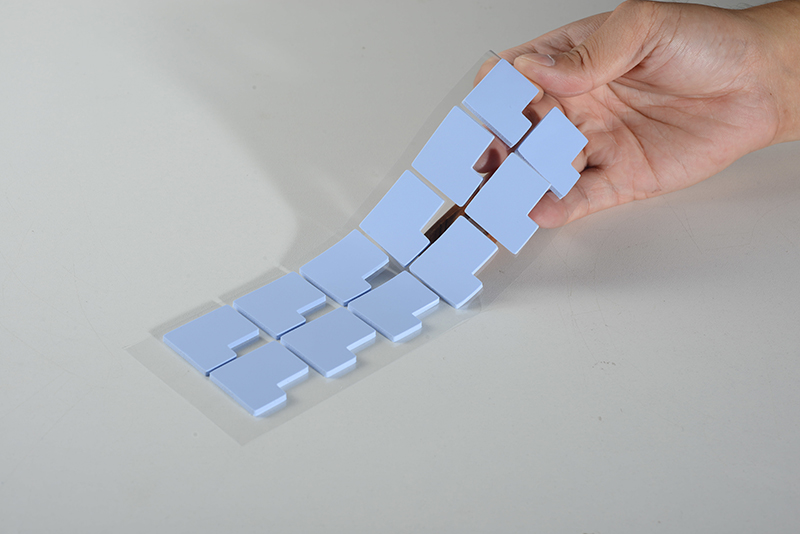

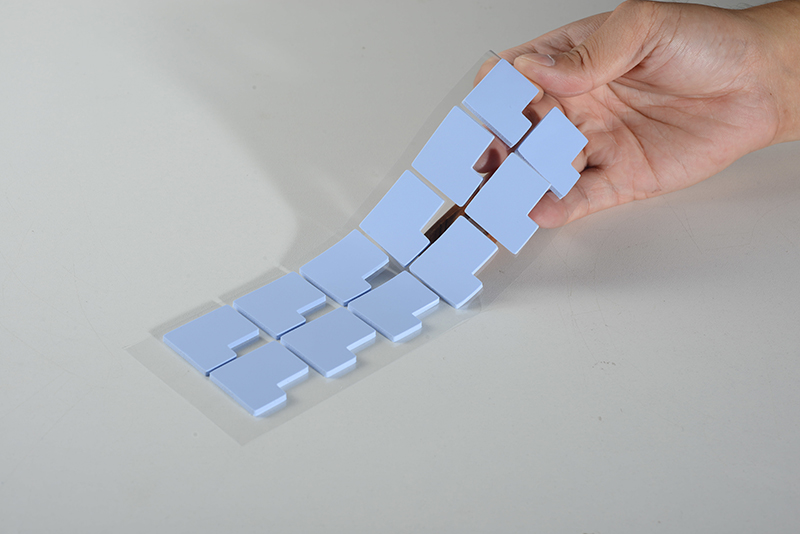

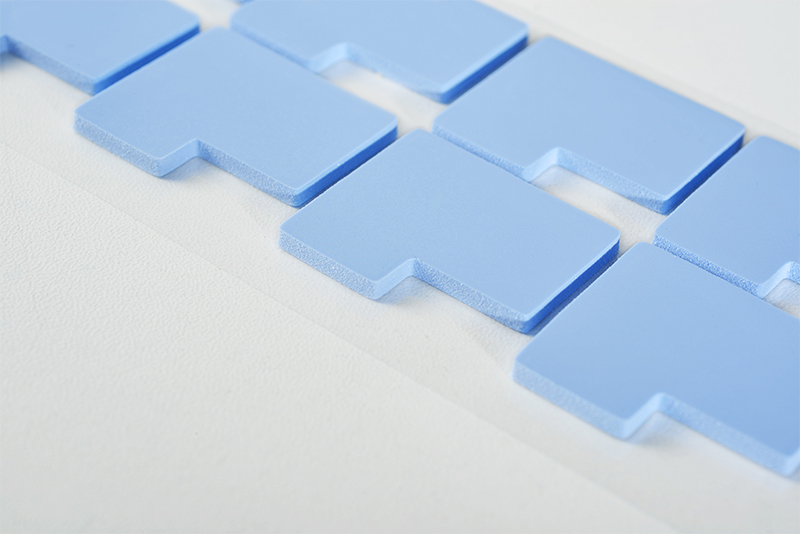

Thermal conductive silicone pads are widely used in electronic devices and other applications that require heat dissipation. These materials not only have excellent thermal conductivity but also possess elasticity, allowing them to form good thermal contact between two surfaces. However, understanding the elastic modulus of thermal conductive silicone pads is crucial when selecting and using them. This article will explore the significance of the elastic modulus, its measurement methods, and its impact on practical applications.

The elastic modulus, also known as Young's modulus, measures a material's resistance to elastic deformation. It defines the degree of deformation a material undergoes when subjected to stress (force). The elastic modulus is measured in Pascals (Pa), often expressed in larger units like Megapascals (MPa) or Gigapascals (GPa).

Mathematically, the elastic modulus E is expressed as:

E = σ/ϵ

where σ is stress and ϵ is strain. Stress is the force applied to a material divided by its cross-sectional area, while strain is the deformation of the material relative to its original length.

Elastic Modulus of Thermal Conductive Silicone Pads

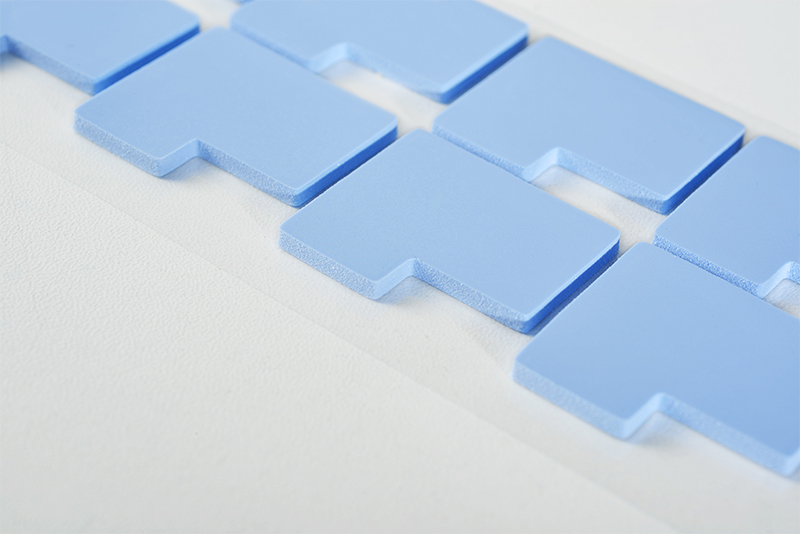

Thermal conductive silicone pads are soft, highly elastic materials with a much lower elastic modulus than metals and ceramics. This low elastic modulus allows the pads to conform to different surface shapes and pressures, ensuring good thermal contact.

Importance of Elastic Modulus

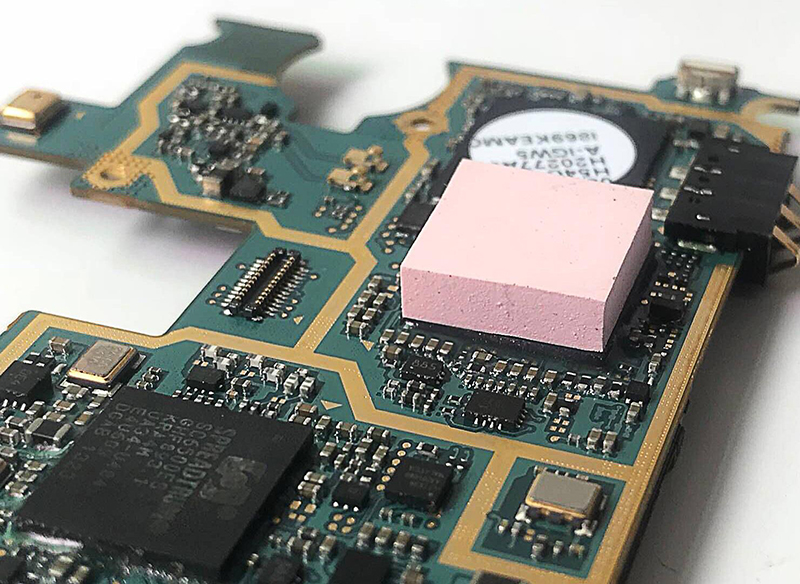

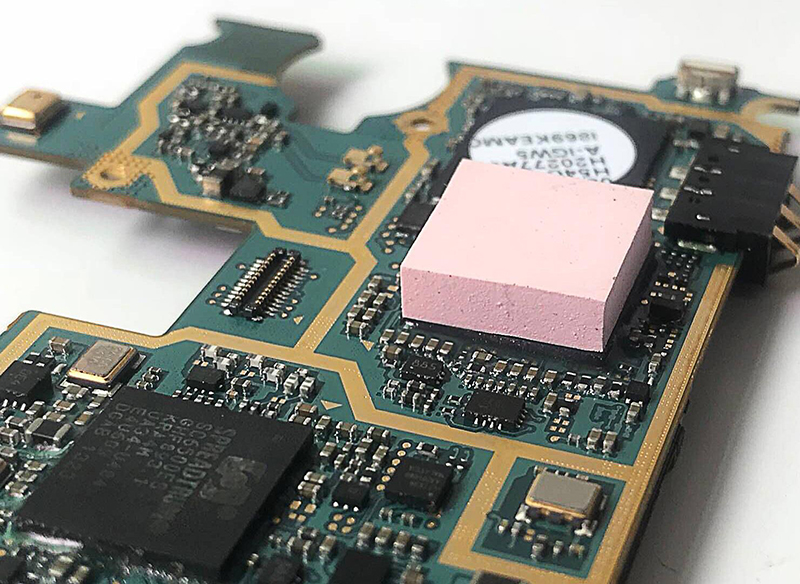

1. Thermal Interface Performance: The primary function of thermal conductive silicone pads is to act as thermal interface materials (TIMs), filling the gaps between heat sources and heat sinks. A low elastic modulus allows the pads to deform under low pressure, filling in tiny surface irregularities and improving thermal conductivity.

2. Mechanical Stress Distribution: In electronic devices, thermal conductive silicone pads help distribute stress caused by thermal expansion and mechanical vibrations, protecting sensitive electronic components from damage.

3. Ease of Installation: Due to their softness and low elastic modulus, thermal conductive silicone pads are easy to cut and install, fitting various shapes and sizes of surfaces.

Measuring the Elastic Modulus of Thermal Conductive Silicone Pads

The elastic modulus of thermal conductive silicone pads is typically measured using tensile or compression tests. Below are the basic steps for both methods:

Tensile Test

1. Prepare the Sample: Cut the thermal conductive silicone pad into standard-sized samples.

2. Mount the Sample: Secure the sample in a tensile testing machine.

3. Apply Force: Gradually apply force and record stress and strain data.

4. Calculate Elastic Modulus: Determine the elastic modulus from the stress-strain curve.

Compression Test

1. Prepare the Sample: Cut the thermal conductive silicone pad into appropriately sized samples.

2. Mount the Sample: Secure the sample in a compression testing machine.

3. Apply Pressure: Gradually apply pressure and record stress and strain data.

4. Calculate Elastic Modulus: Determine the elastic modulus from the stress-strain curve.

Impact of Elastic Modulus in Practical Applications

Understanding the elastic modulus helps engineers evaluate the performance of thermal conductive silicone pads in specific applications. For example, in high-pressure environments, a pad with a low elastic modulus might not provide sufficient support, while in low-pressure environments, it can ensure better thermal contact.

Additionally, the elastic modulus affects the durability and reliability of thermal conductive silicone pads. In repeated thermal cycles and mechanical stress, materials with a higher elastic modulus might be more durable, while those with a lower modulus might deform and fail more easily.

Conclusion

The elastic modulus of thermal conductive silicone pads is a crucial performance indicator that directly impacts their effectiveness in thermal interface management. Understanding and accurately measuring the elastic modulus helps engineers select suitable pads for specific applications, ensuring reliable and efficient operation of electronic devices. By choosing pads with the appropriate elastic modulus, the thermal management performance and lifespan of devices can be significantly improved.

CN >

CN >