In the realm of thermal management, particularly in electronic devices and high-performance engineering applications, the role of thermal conductive materials is pivotal. Among these materials, thermal conductive silicone sheets are widely used due to their excellent thermal conductivity, flexibility, and ease of use. However, to further enhance their performance, the addition of glass fiber is increasingly recognized as a valuable modification. This article explores why incorporating glass fiber into thermal conductive silicone sheets can be highly advantageous, examining the key benefits, underlying mechanisms, and implications for various applications.

The Basics of Thermal Conductive Silicone Sheets

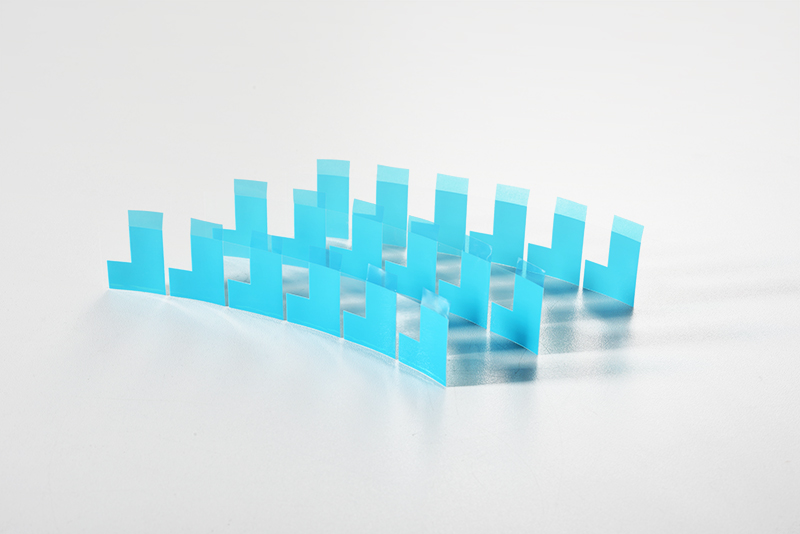

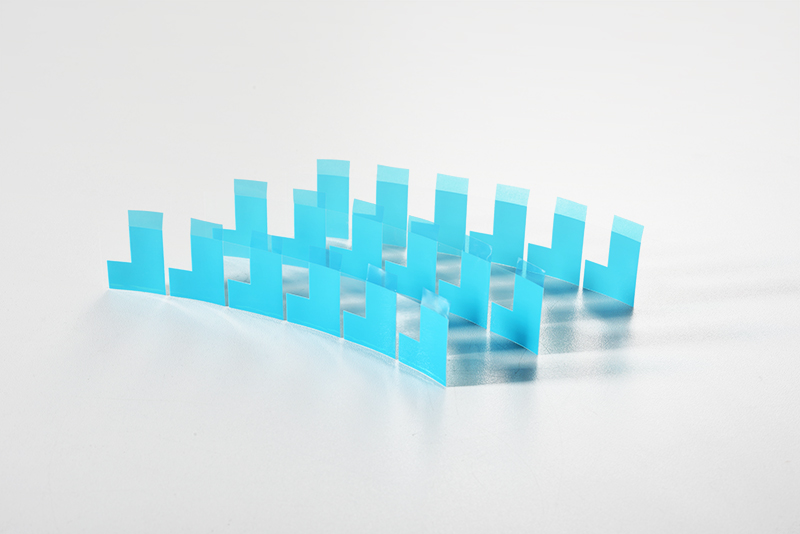

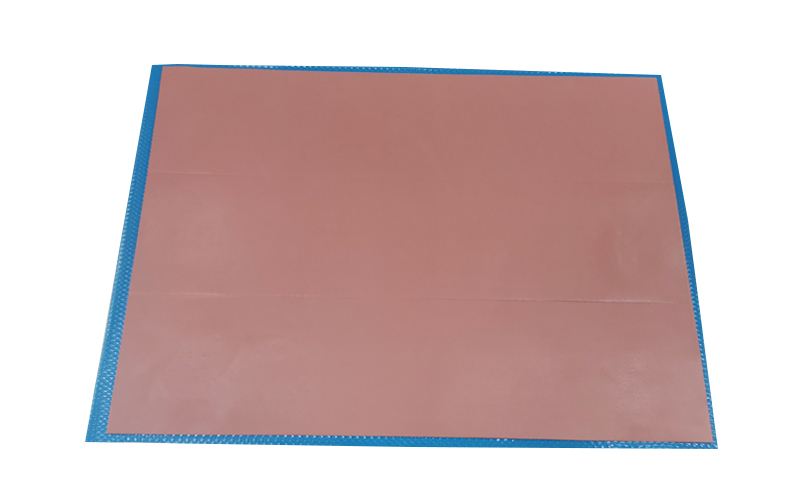

Thermal conductive silicone sheets are engineered to facilitate efficient heat dissipation in electronic assemblies, reducing the risk of overheating and ensuring the reliable operation of devices. These sheets are typically composed of silicone rubber, which is combined with thermal conductive fillers such as metal oxides or silicon carbide to enhance heat transfer capabilities. The intrinsic flexibility and conformability of silicone sheets make them ideal for applications where thermal interface materials need to adapt to varying surfaces and geometries.

Enhancing Mechanical Strength with Glass Fiber

One of the primary reasons to incorporate glass fiber into thermal conductive silicone sheets is to bolster their mechanical strength. Glass fiber is known for its high tensile strength and rigidity, which can significantly improve the structural integrity of the silicone sheet. This enhancement is particularly beneficial in applications where the silicone sheet is subjected to mechanical stresses, such as in high-vibration environments or when used as a thermal interface material in complex assemblies.

1. Increased Durability

Glass fiber reinforcement enhances the durability of silicone sheets by preventing deformation and maintaining the material's shape under pressure. This increased durability is crucial in high-performance applications where the silicone sheet must endure repeated mechanical stress without compromising its thermal conductivity or structural integrity.

2. Improved Dimensional Stability

Incorporating glass fiber helps maintain the dimensional stability of the silicone sheet over time and under varying temperatures. This stability ensures that the sheet remains effective as a thermal interface material, providing consistent thermal performance and reliability throughout its service life.

Enhancing Thermal Conductivity

While silicone sheets inherently possess good thermal conductivity, the addition of glass fiber can further optimize their thermal performance. Glass fiber itself does not contribute to thermal conductivity, but its inclusion helps achieve a more uniform distribution of thermal conductive fillers within the silicone matrix.

1. Better Heat Distribution

The presence of glass fiber can help in achieving a more homogeneous dispersion of thermal conductive fillers, which in turn enhances the uniformity of heat distribution across the silicone sheet. This improved distribution minimizes localized hotspots and ensures more effective heat dissipation.

2. Controlled Thermal Expansion

Glass fiber reinforcement can help manage the thermal expansion characteristics of the silicone sheet. By reducing the overall expansion rate, the sheet can maintain its thermal interface properties more effectively, especially in applications where thermal cycling is a concern.

Practical Applications and Considerations

The integration of glass fiber into thermal conductive silicone sheets offers numerous benefits across a variety of applications. These enhanced properties make the modified sheets suitable for use in high-power electronics, automotive components, and aerospace engineering.

1. High-Power Electronics

In high-power electronics, where efficient heat dissipation is critical to prevent overheating, the added mechanical strength and improved thermal performance provided by glass fiber reinforcement are invaluable. These sheets can reliably manage the heat generated by high-power components, ensuring stable operation and extending the lifespan of the electronic devices.

2. Automotive and Aerospace Applications

In the automotive and aerospace industries, where components are often exposed to harsh conditions and extreme temperatures, the enhanced durability and thermal management capabilities of glass fiber-reinforced silicone sheets are particularly advantageous. These sheets can withstand vibration, thermal cycling, and mechanical stress, making them suitable for critical applications in these sectors.

Conclusion

The addition of glass fiber to thermal conductive silicone sheets represents a significant advancement in material engineering, offering improved mechanical strength, durability, and enhanced thermal performance. By integrating glass fiber, manufacturers can produce silicone sheets that not only excel in heat dissipation but also withstand the rigors of demanding applications. As technology continues to advance and the performance requirements for thermal management materials increase, the role of such innovative solutions becomes ever more crucial. For engineers and designers, understanding and leveraging these benefits can lead to more efficient and reliable thermal management solutions across various industries.

CN >

CN >