Thermal materials play a crucial role in electronic devices and thermal management systems. They primarily function to conduct heat efficiently, thereby reducing component temperatures, extending device lifespan, and enhancing performance. Among these materials, thermal grease and thermal gel are commonly used options. Although they share similarities in applications, they have significant differences in performance, usage, and characteristics. NFION will explore these differences in detail to help readers make informed decisions when choosing the appropriate thermal material.

Thermal Grease

Definition and Composition

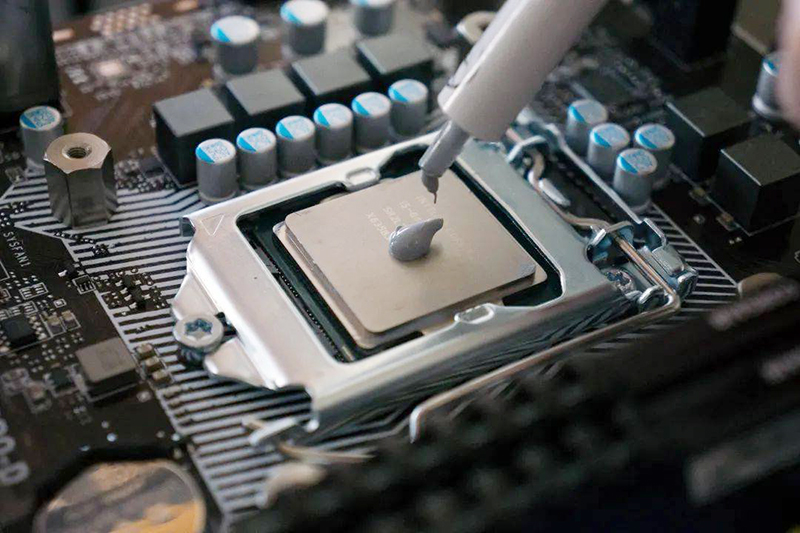

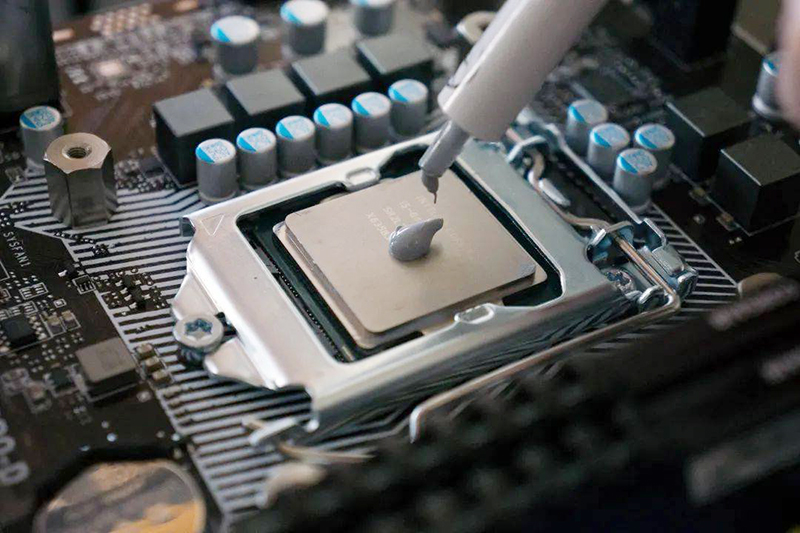

Thermal grease, also known as thermal paste, is typically composed of silicone oil mixed with thermally conductive particles such as aluminum oxide, boron nitride, or metal powders. Its primary function is to fill the microscopic gaps between electronic components and heat sinks, thereby improving thermal conductivity.

Advantages

● High Thermal Conductivity: Thermal grease usually has a high thermal conductivity, efficiently transferring heat.

● Easy Application: Its viscous nature makes it easy to apply to surfaces requiring heat dissipation.

● Wide Applicability: Suitable for various electronic devices, from computer CPUs to high-power LED lighting systems.

Disadvantages

● Complex Maintenance: Thermal grease may dry out or flow over time, necessitating periodic reapplication.

● Risk of Short Circuit: Improper use of certain metal-filled thermal greases can lead to short circuits in electronic components.

Thermal Gel

Definition and Composition

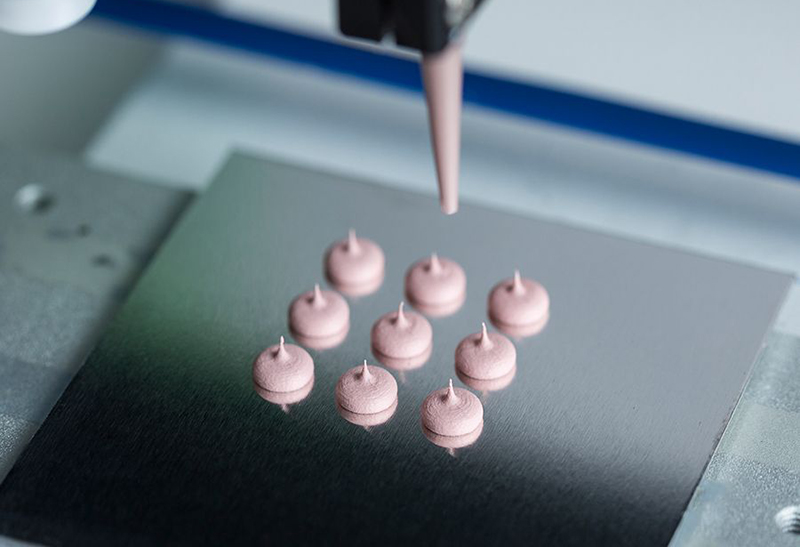

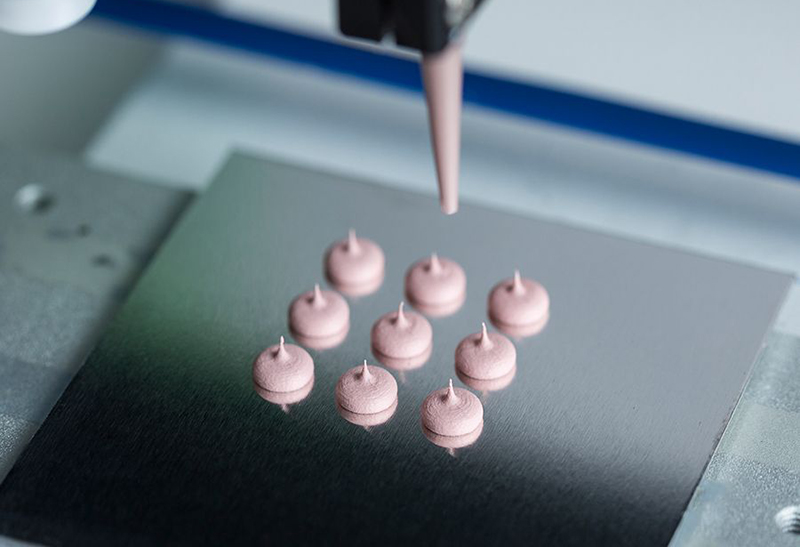

Thermal gel is a newer type of thermal material, typically consisting of silicone gel and thermally conductive fillers. Compared to thermal grease, thermal gel has a softer texture and certain viscoelastic properties.

Advantages

● High Stability: Thermal gel has high stability and is less likely to fail due to temperature changes or over time.

● Long-term Reliability: It does not dry out or flow, making it more reliable over long-term use.

● Excellent Filling Performance: Thermal gel can better fill microscopic gaps, providing more efficient heat transfer.

Disadvantages

● Higher Cost: Thermal gel is generally more expensive than thermal grease.

● Application Limitations: In certain high-compression environments, thermal gel may not perform as well as thermal grease.

Performance Comparison

Thermal Performance

Both thermal grease and thermal gel have their merits. Thermal grease typically performs better initially, but its performance may degrade over time. In contrast, thermal gel maintains high thermal performance over long-term use due to its stable nature.

Reliability and Lifespan

Thermal grease requires periodic maintenance and reapplication, adding complexity to its use. Conversely, thermal gel’s high stability and longevity make it more advantageous for applications requiring long-term reliability.

Applicability

Thermal grease is suitable for devices that need frequent maintenance and adjustments, whereas thermal gel is ideal for environments where maintenance is challenging, such as embedded systems or sealed devices.

Application Examples

Thermal Grease Applications

1. Computer CPUs and GPUs: Due to its high thermal conductivity and ease of application, thermal grease is commonly used in computer processors and graphics cards.

2. High-power LED Lighting: Thermal grease effectively conducts heat in LED lighting systems, extending the lifespan of LEDs.

Thermal Gel Applications

1. New Energy Vehicle Batteries: Thermal gel is widely used in new energy vehicle battery systems to ensure thermal management and safety.

2. Communication Devices: Increasingly used in communication devices requiring long-term reliability.

5. Conclusion

Both thermal grease and thermal gel have their advantages and disadvantages. Choosing the right thermal material depends on specific application requirements and environmental conditions. Thermal grease is suitable for high thermal conductivity and easy maintenance applications, while thermal gel performs better in applications requiring long-term stability and reliability. Understanding their differences and characteristics can help in making informed decisions, effectively enhancing device performance and lifespan.

CN >

CN >