In the era of rapid development of high-tech devices, heat dissipation has become one of the key factors affecting the performance enhancement of electronic devices. To address this issue, thermal interface materials, particularly thermal silicone pads, have been widely adopted across multiple sectors including electronics, LED lighting, computer hardware, and new energy vehicles, thanks to their excellent thermal conductivity and flexibility. However, as public health consciousness rises, debates surrounding the toxicity of thermal silicone pads have grown increasingly prominent. This article delves into the composition, safety assessment, environmental standards, and practical applications of thermal silicone pads, aiming to provide readers with a thorough and professional response.

Basic Composition of Thermal Silicone pads

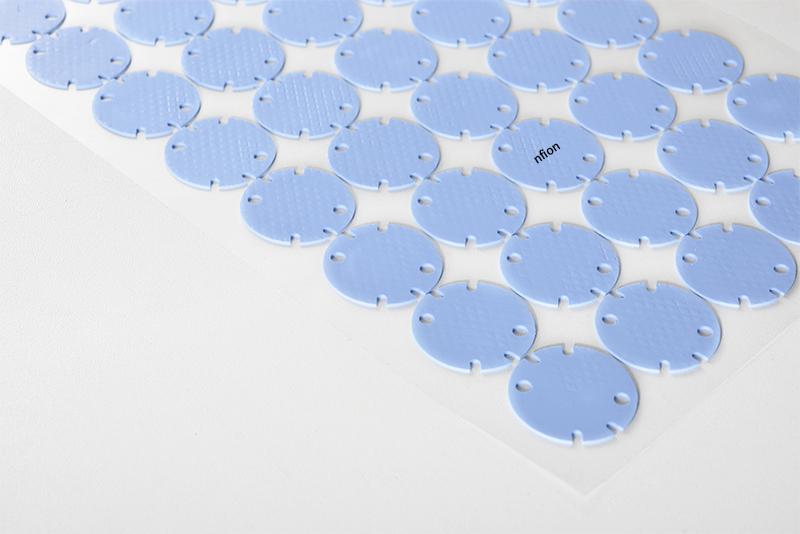

Thermal silicone pads are polymer materials primarily made from silicone rubber, with thermally conductive fillers (such as aluminum oxide, boron nitride, etc.) added through special processes. Characterized by high flexibility, compressibility, and efficient heat transfer capabilities, they effectively dissipate heat within confined spaces, thereby safeguarding electronic components against heat damage.

Safety Analysis of Thermal Silicone pads

Ingredient Safety

Silicone Rubber Base: Silicone rubber itself is a relatively safe polymer material known for its good biocompatibility and chemical stability, commonly used in medical and food contact applications. Under normal conditions, silicone rubber does not easily volatilize or decompose, posing minimal harm to humans.

Thermal Conductive Fillers: Common fillers like aluminum oxide and boron nitride are inorganic substances with stable chemical properties that do not evaporate or emit toxic gases. These fillers, prevalent in nature, have long-standing industrial applications with minimal impact on human health and the environment.

Processing Additives: The production of thermal silicone pads may involve adding small amounts of crosslinking agents, catalysts, etc., to enhance product performance. Selection and dosage of these additives must be strictly controlled to ensure compliance with relevant safety standards. Modern manufacturing trends favor low-toxicity or non-toxic additives, minimizing potential risks to the environment and human health.

Safety Assessment of Thermal Silicone pads

Toxicological Data: Currently, there is no compelling toxicological data indicating any components in thermal silicone pads pose a direct threat to human health.

Environmental Impact: Thermal silicone pads do not generate harmful substances during use, having a minor environmental footprint.

Usage Safety: Under normal usage conditions, thermal silicone pads do not release toxic gases or liquids, rendering them safe.

Environmental & Safety Standards

To ensure consumer safety and environmental protection, international regulations such as the EU's RoHS Directive (restricting specific hazardous substances in electrical and electronic equipment), REACH regulations (registration, evaluation, authorization, and restriction of chemicals), and the UL certification in the US, set stringent standards for electronic materials. Thermal silicone pads, as integral components of electronic devices, must adhere to these standards, guaranteeing the absence of harmful substances like lead, mercury, cadmium, hexavalent chromium, and ensuring no pollution during regular use and disposal.

Considerations in Practical Applications

While qualified thermal silicone pads are deemed safe based on composition and standards, practical applications should consider:

Proper Selection: Different electronic products require thermal silicone pads with varying performance specifications. Choosing the right product can minimize potential safety hazards.

Choosing Safe Thermal Silicone pads

Consumers can consider the following when selecting safe and reliable thermal silicone pads:

1.Opt for reputable brands and manufacturers: These typically have more robust quality management systems and testing methods to ensure product quality and safety.like Nfion Thermal.

2.Check for product certifications and test reports: Such as UL and CE certifications, which attest to product conformity with relevant standards and regulations.

3.Focus on product ingredients and performance indicators: Understanding the product's composition and performance metrics, e.g., thermal conductivity, hardness, tensile strength, ensures product suitability.

Operation & Maintenance: Follow manufacturer guidelines during installation, wearing appropriate personal protective equipment to prevent material debris from entering the respiratory system or eyes. Regular inspections and maintenance ensure optimal functioning and prevent safety issues from aging or damage.

Disposal: Although thermal silicone pads have minimal environmental impact, follow local environmental regulations for proper recycling or disposal to avoid pollution from indiscriminate discarding.

Conclusion

In summary, thermal silicone pads, as an efficient and adaptable heat dissipation solution, are designed and manufactured with safety and environmental considerations in mind. Properly sourced and used thermal silicone pads, with their components and production processes stringently regulated, are safe for users and the environment. Nevertheless, adherence to safety protocols and personal protection during use remains crucial. With technological advancements and rising environmental standards, future thermal silicone pads will further enhance their eco-friendly properties while maintaining effective heat dissipation, contributing positively to the green development of electronic technology.

CN >

CN >