In electronic devices and various heat dissipation systems, thermal conductive silicone grease is a common and crucial material. It is mainly used to fill the tiny gaps between heating elements and heat sinks to improve the efficiency of heat conduction and ensure the normal operation and stability of the equipment. However, whether thermal conductive silicone grease has the function of preventing rust is a frequently overlooked but rather practical issue.

First of all, let's understand the basic characteristics of thermal conductive silicone grease. Thermal conductive silicone grease usually consists of silicone oil, thermal conductive fillers (such as aluminum oxide, zinc oxide, etc.) and various additives. Its main role is to reduce the contact thermal resistance so that the heat can be transferred more smoothly from the heating element to the heat sink. Due to its good thermal conductivity and the ability to adapt to various complex interfaces, thermal conductive silicone grease has been widely used in the fields of computers, electronic devices, automobiles, and so on.

Then, back to our core question: Does thermal conductive silicone grease prevent rust? To answer this question, we need to analyze from several aspects.

From the perspective of composition, the silicone oil in thermal conductive silicone grease has certain hydrophobicity and inertness, which means it can prevent water and oxygen from directly contacting the metal surface to a certain extent. However, this does not mean that it can completely prevent metal from rusting. In some cases, if there are corrosive gases or liquids in the environment, the silicone oil may not provide sufficient protection.

The thermal conductive fillers in thermal conductive silicone grease are usually some inorganic compounds, such as aluminum oxide. These fillers themselves do not have the function of preventing rust, but their existence may have a certain impact on rust prevention. For example, some fine filler particles may fill in the tiny defects on the metal surface, thereby to a certain extent preventing the invasion of corrosive substances. But this protective effect is very limited and may gradually fail over time.

In addition, the additives in thermal conductive silicone grease may also have an impact on rust prevention. Some additives may have antioxidant or corrosion-inhibiting functions, which can slow down the rusting speed of metals to a certain extent. However, the content of these additives is usually relatively low, and their rust prevention effects are relatively limited.

In practical applications, whether thermal conductive silicone grease can play the role of rust prevention also depends on many other factors. For example, the use environment of the equipment is a very important factor. If the equipment is in a dry and clean environment, the possibility of metal rusting is relatively small, and at this time, thermal conductive silicone grease may be able to provide a certain auxiliary rust prevention effect. But if the equipment is in a humid and corrosive environment, the rust prevention effect of thermal conductive silicone grease may be greatly reduced.

In addition, the treatment method of the metal surface will also affect the rust prevention effect of thermal conductive silicone grease. If the metal surface has undergone appropriate rust prevention treatment such as phosphating and galvanizing before coating with thermal conductive silicone grease, then thermal conductive silicone grease combined with the rust prevention treatment layer may provide better rust prevention effects. But if the metal surface has not undergone any rust prevention treatment and only relies on thermal conductive silicone grease to prevent rust, its effect is usually not ideal.

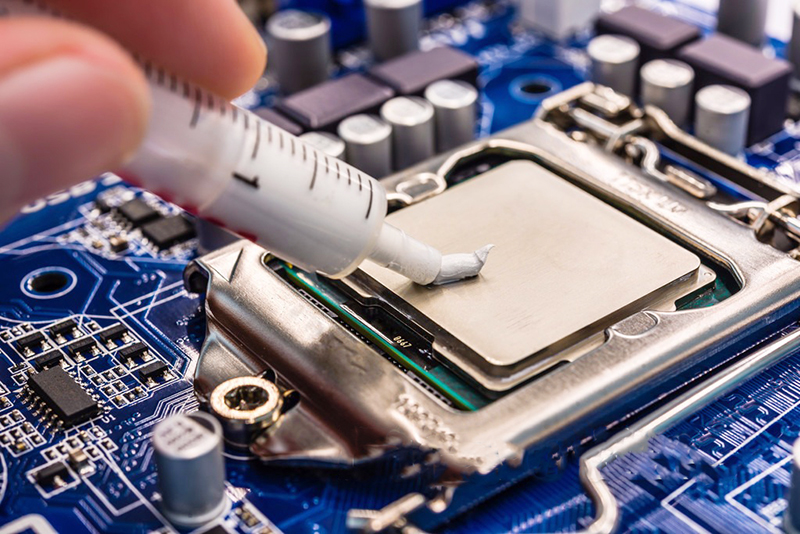

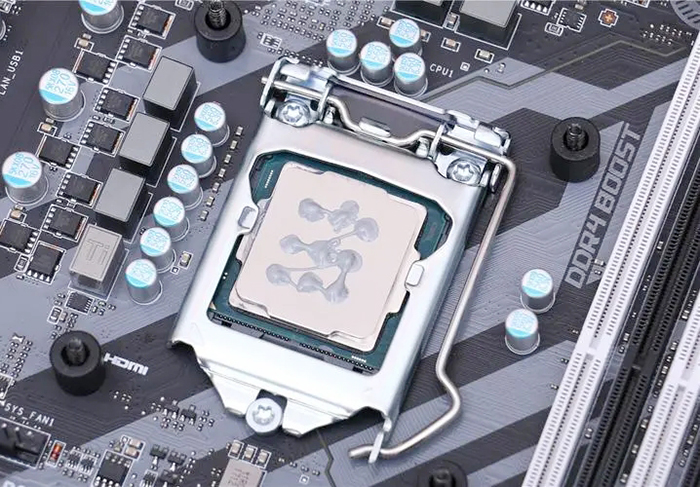

To better understand the rust prevention effect of thermal conductive silicone grease, we can look at some specific examples. In the computer field, thermal conductive silicone grease is usually applied between the CPU and the heat sink. Under normal circumstances, the thermal conductive silicone grease in this application scenario mainly plays the role of heat conduction, and the demand for rust prevention is relatively low. Because computers are usually used in indoor environments and the environment is relatively stable, the risk of metal rusting is small. However, if the computer is in a high humidity or corrosive environment for a long time, even if thermal conductive silicone grease is applied, metal components such as CPU pins may still show signs of rusting.

In the field of automotive electronics, some electronic control units (ECUs) and sensors also use thermal conductive silicone grease. Since the car will face various harsh environmental conditions such as high temperature, high humidity, and corrosive substances during driving, the rust prevention requirements for metal components are relatively high. In this case, relying solely on thermal conductive silicone grease to prevent rust is far from enough. Usually, special rust prevention treatments such as galvanizing and coating with rust prevention paint are also required.

To improve the rust prevention effect of thermal conductive silicone grease, the following methods can be considered:

One is to choose thermal conductive silicone grease containing rust prevention additives. There are some thermal conductive silicone grease products specifically designed for rust prevention needs on the market, and these products add more rust prevention additives, which can improve the rust prevention effect to a certain extent.

The second is to perform appropriate rust prevention treatment on the metal surface before coating with thermal conductive silicone grease. For example, the metal surface can be phosphated with phosphating solution or coated with a layer of rust prevention paint.

The third is to pay attention to the use environment of the equipment. Try to avoid the equipment being in a humid and corrosive environment. If it cannot be avoided, some protective measures can be taken, such as installing a waterproof cover.

The fourth is to regularly inspect and maintain the equipment. Discover the signs of metal rusting in time and take corresponding treatment measures, such as removing rust and re-applying rust prevention treatment layers.

In conclusion, thermal conductive silicone grease itself does not have a very strong rust prevention function, but may have a certain auxiliary effect on metal rusting under certain conditions. In practical applications, the rust prevention effect of thermal conductive silicone grease needs to be comprehensively considered and selected according to the specific use environment and needs. If there are high requirements for metal rust prevention, we cannot rely only on thermal conductive silicone grease, but also need to take other more comprehensive and effective rust prevention measures. At the same time, regular inspection and maintenance are also important measures to ensure the long-term stable operation of the equipment and prevent metal rusting.

CN >

CN >