In today's era of rapid technological advancement, portable electronic devices such as Bluetooth speakers have gained immense popularity among consumers due to their wireless convenience and exceptional audio quality. However, as technology progresses and users demand higher performance from these products, miniaturization and high performance in design trends have also introduced unprecedented challenges in heat dissipation. This is particularly true for Bluetooth speakers that integrate high-power audio amplifiers, digital signal processors (DSPs), and batteries – all heat-generating components. Ensuring efficient heat dissipation to guarantee long-term stable operation has thus become a crucial technical challenge for designers. It is against this backdrop that thermal conductive silicone pads, with their unique material properties and application advantages, have gradually emerged as the key solution to addressing the heat dissipation issues of Bluetooth speakers.

- Performance Degradation: High temperatures can impair the performance of electronic components, reducing the stability of Bluetooth signal transmission, affecting the output power of audio amplifiers, and thereby causing audio quality deterioration and unstable connections.

- Reduced Lifespan: Prolonged exposure to high temperatures accelerates the aging of electronic components, shortening the lifespan of Bluetooth speakers.

Traditional cooling methods, including metal heat sinks and fans, have been employed to address these heat dissipation challenges. Nonetheless, these approaches have limitations, such as limited heat dissipation efficiency of metal heat sinks and noise generation by fans, necessitating the exploration of a more efficient and reliable cooling solution.

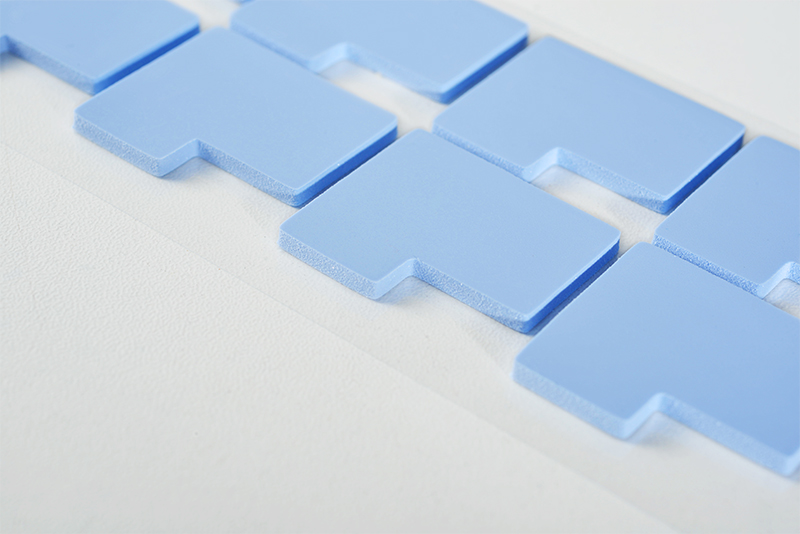

1. Excellent Thermal Conductivity: With thermal conductivity coefficients ranging from 1.0W/mK - 12.0W/mK, these pads allow for the selection of suitable models based on different applications to effectively transmit heat generated by electronic components and reduce localized hotspots.

2. Superior Flexibility and Compressibility: The soft and elastic nature of silicone enables adaptation to various uneven surfaces and maintains good contact even under vibration or deformation, ensuring unobstructed heat transfer paths.

3. Insulation: As insulating materials, they provide efficient heat conduction while preventing short circuits, ensuring the safe operation of electronic devices.

4. Weather Resistance and Reliability: With excellent temperature resistance and anti-aging properties, they maintain stable physical properties within a wide temperature range of -40 to 200°C, making them suitable for long-term use in various environments.

5. Low Stress: Thermal conductive silicone pads generate minimal stress during installation and use, avoiding damage to electronic components.

6. Environmentally Friendly and Non-Toxic: Typically made from eco-friendly, non-toxic materials, they are harmless to humans and the environment.

7. Ease of Installation: Unlike traditional metal heat sinks or thermal paste, thermal conductive silicone pads can be cut into any shape for easy installation. They leave no residue during disassembly or maintenance, enhancing production efficiency and ease of maintenance.

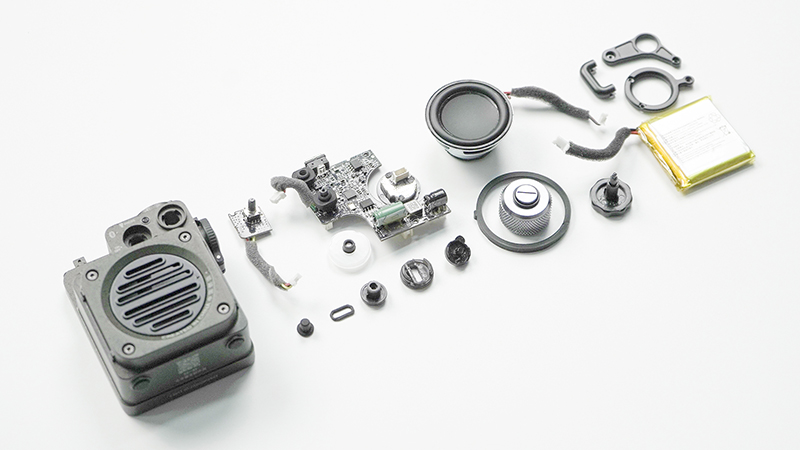

- Between the Bluetooth module and the enclosure: As one of the major heat-producing components in Bluetooth speakers, placing thermal conductive silicone pads between the Bluetooth module and the enclosure quickly conducts heat from the module to the enclosure for dissipation.

- Between the audio amplifier and heat sink: Audio amplifiers, being high-power components, generate significant heat during operation. The placement of thermal conductive silicone pads between the amplifier and heat sink enhances heat conduction efficiency and lowers the amplifier’s temperature.

- Between the battery and the enclosure: Batteries generate heat during charging and discharging. Placing thermal conductive silicone pads between the battery and the enclosure conducts this heat to the enclosure, preventing overheating of the battery.

- Thermal Conductivity Coefficient: A vital indicator of thermal conductivity performance, a higher coefficient generally indicates better performance. Selection should be based on the speaker's cooling requirements.

- Thickness: Affects heat conduction efficiency and installation difficulty. Thinner pads offer better conductivity but increase installation complexity. Thickness should be chosen based on the speaker's structure and cooling needs.

- Surface Cleaning: Prior to installation, clean the surfaces of electronic components and heat sinks or enclosures to ensure effective heat transfer.

- Accurate Cutting: Tailor the thermal conductive silicone pad according to component and heat sink dimensions to avoid misfit.

CN >

CN >