With the flourishing development of the fifth generation mobile communication technology (5G), we are stepping into a new era characterized by faster data transmission speeds, broader connectivity, and lower latency. However, accompanying these technological leaps are unprecedented thermal management challenges. The high-density integration, high-power output, and continuous operation demands of 5G devices lead to heat generation far exceeding previous levels, posing severe tests to device reliability and performance. It is against this backdrop that high-performance thermal management materials have become an indispensable cornerstone of the 5G era. This article delves into the significance of thermal management materials in 5G applications, analyzes their technical advantages, and provides guidance for users in material selection.

Heat Dissipation Issues in 5G Devices

During operation, 5G devices generate substantial heat, primarily due to the following factors:

- Higher Communication Frequencies: 5G networks utilize higher frequencies than 4G, resulting in greater energy loss during signal transmission, which is then converted into heat.

- Increased Data Traffic: 5G’s capability to support larger data volumes necessitates higher power consumption by components such as processors and RF modules, leading to increased heating.

- Denser Device Layout: To achieve smaller and thinner 5G device designs, internal components are arranged more densely, facilitating heat accumulation.

Thus, thermal management materials, as the key to addressing heat dissipation issues, see their performance and application become critically important.

Overview of Thermal Management Materials

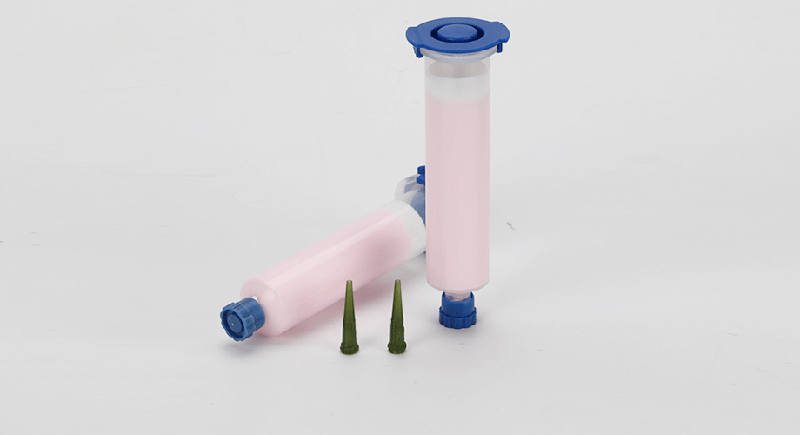

Thermal management materials are a class of materials specifically designed to control and regulate heat transfer. They enhance heat conduction, convection, and radiation to efficiently dissipate heat. In 5G applications, these materials are mainly categorized into conductive fillers (like graphene, boron nitride), phase change materials, thermal interface materials (TIMs), and cooling coatings, each serving different mechanisms to facilitate efficient heat transfer or storage, thereby controlling and reducing internal device temperatures.

Characteristics and Performance of Thermal Management Materials

- High Thermal Conductivity: This is a core characteristic, enabling rapid heat transfer from heat sources to cooling components such as heat sinks or heat pipes.

- Low Thermal Resistance: Minimizing resistance allows smoother heat flow with minimal loss, enhancing cooling efficiency.

- Good Insulating Properties: Materials must insulate electronic components to prevent short circuits while facilitating heat transfer.

- Stability and Durability: These materials must maintain stable performance under varying conditions and have a long service life.

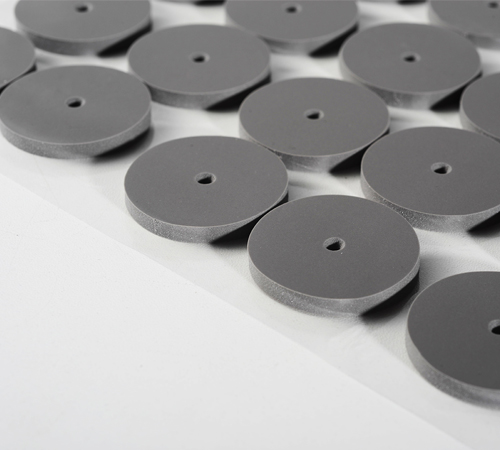

- Adaptability and Processability: They should fit diverse 5G designs, being moldable into various shapes and sizes for specific installations.

Advantages of Thermal Management Materials in 5G Applications

- Enhanced Cooling Efficiency: Their superior thermal conductivity rapidly transfers heat, maintaining low internal temperatures for stable operation and prolonged lifespan, especially crucial in high-power density scenarios like 5G base stations and devices.

- Reduced Cooling Space Requirements: With limited space due to high integration, these materials optimize heat paths for efficient cooling within tight confines.

- Lower Energy Consumption and Costs: Efficient cooling reduces temperature-related energy increases and performance degradation, simplifying cooling systems and reducing costs, vital for mass production and deployment of 5G devices.

- Improved Reliability and Stability: Overheating is a primary cause of device failure; thermal management materials ensure stability, critical for 5G’s continuous operation under temperature sensitivity.

- Adaptation to Complex Environments: 5G devices operate in varied conditions; advanced materials withstand these environments while maintaining efficient cooling.

Specific Application Cases of Thermal Management Materials in 5G

- 5G Base Station Equipment: Essential for network stability, these generate considerable heat. Graphene cooling plates are used in power amplifiers and high-power components for rapid heat transfer.

- Smartphones: 5G adoption increases data speed and power consumption, leading to heat issues. Premium smartphones integrate graphene films for heat dispersion, maintaining cool operation.

- Data Centers: Supporting 5G networks, they house servers generating significant heat. Efficient air cooling systems with copper or aluminum substrates, or liquid cooling with heat pipes, ensure effective heat management.

- Millimeter Wave Radars: Key for autonomous vehicles, these operate at high frequencies with substantial heat output. High thermal conductivity TIMs and heat sinks ensure radar reliability.

User Selection Guide

When selecting thermal management materials, consider:

- The operating environment,

- Specific thermal management needs,

- Cost-effectiveness,

- And sustainability, prioritizing eco-friendly options.

Conclusion

Thermal management materials are pivotal to the performance and longevity of 5G devices. Advancements in material science will continue to propel innovations in 5G and future 6G technologies. Understanding the characteristics and advantages of these materials is crucial for efficient, reliable, and sustainable 5G applications. As a professional thermal management material manufacturer, NFION offers comprehensive solutions, partnering with industry leaders to address the challenges and opportunities presented by the 5G era.

CN >

CN >