Which Thermal Interface Material Is Best for GPU Cooling? A Full Comparison of Pads, Grease, and Gel

Introduction: The Key to GPU Stability Lies Beyond Compute Power

As AI computing, graphics rendering, and high-performance workloads continue to grow, the thermal design power (TDP) of GPUs is increasing rapidly.

When power consumption exceeds 300W or even 500W, thermal management becomes the decisive factor that determines performance stability and long-term reliability.

Its purpose is to fill microscopic gaps, eliminate trapped air, and create an efficient thermal conduction path, ensuring heat is transferred away from the GPU effectively.

This article analyzes three common TIMs used in GPU thermal design — thermal pads, thermal grease, and thermal gels — comparing their performance characteristics and application scenarios, followed by practical selection advice.

Core Function of Thermal Interface Materials

Even after precision polishing, the GPU and heatsink surfaces are never perfectly flat.

These micro-voids are filled with air, which has an extremely low thermal conductivity of 0.026 W/m·K.

TIMs fill these voids, establishing a stable thermal path to:

● Reduce interface thermal resistance and enhance heat flow efficiency;

● Equalize temperature distribution, avoiding local hotspots;

● Absorb thermal stress, preventing mechanical deformation;

● Improve long-term reliability under thermal cycling.

In short, a high-quality TIM is the invisible foundation of an efficient GPU cooling system.

Common Types of GPU Thermal Interface Materials

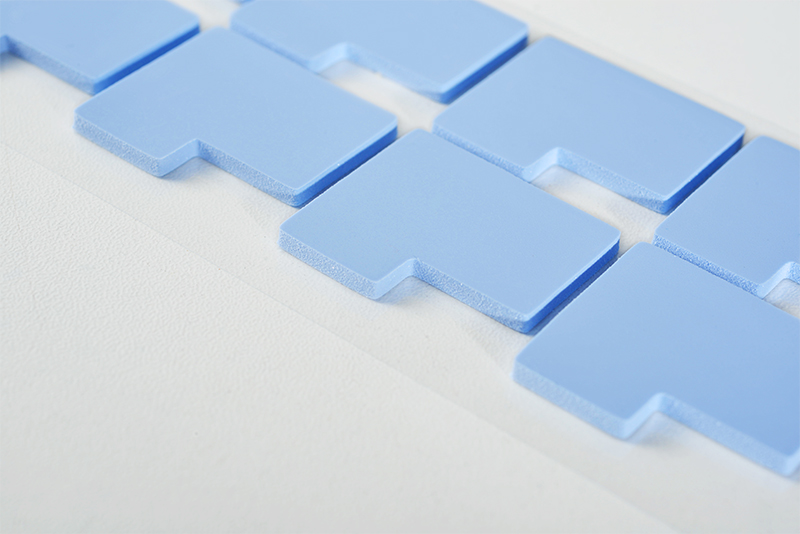

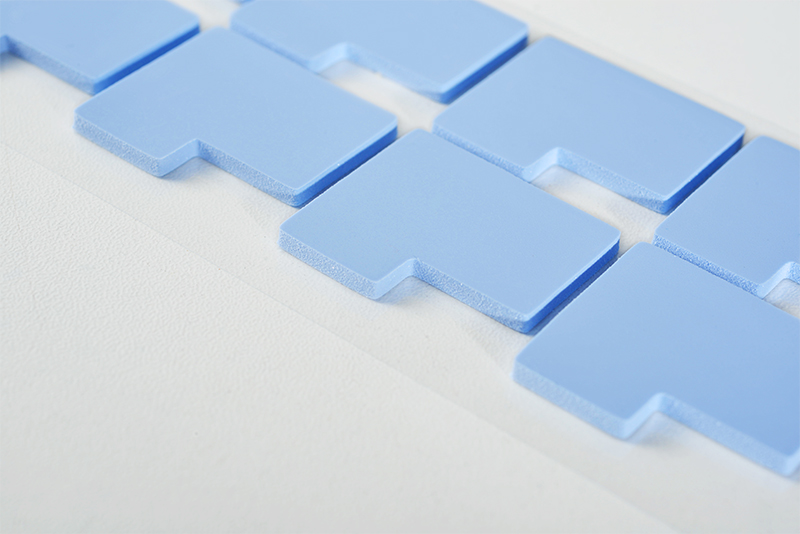

Thermal pads are the most widely used TIMs in GPU modules and server graphics cards.

They are made from a silicone rubber matrix combined with thermally conductive fillers such as alumina, boron nitride, or magnesium oxide.

Thermal Conductivity Range: 1.0 – 12.0 W/m·K

Advantages:

● Excellent compressibility to adapt to various gaps and tolerances;

● High electrical insulation and safety;

● Easy to assemble, suitable for automated production;

● Outstanding long-term stability with no pump-out or cracking.

Typical Applications: GPU modules, VRAM cooling, VRM components, server GPU arrays.

Drawback:

While highly reliable, excessive thickness increases thermal resistance, so pads under 1mm are preferred for high-power GPUs.

Thermal grease is a paste-like material with excellent wettability and interface contact, achieving extremely low contact thermal resistance.

Thermal Conductivity Range: 1.0 – 6.0 W/m·K

Advantages:

● Outstanding thermal transfer efficiency;

● Thin layer, minimal thermal resistance;

● Ideal for short-term extreme cooling demands.

Drawbacks:

● May dry out or experience pump-out effects over time;

● Difficult to clean and reapply;

● Typically non-insulating, requiring careful application.

Typical Applications: High-end desktop GPUs, AI accelerator cards, liquid-cooled GPU systems.

▲ Engineering Tip: For systems with consistent clamping force and extreme thermal needs, thermal grease offers the lowest interface resistance.

Thermal gel is a newer TIM increasingly used in GPU servers and automotive computing systems.

It combines the high conductivity of grease with the stability of pads, featuring semi-solid flowability, low volatility, and long-term reliability.

Thermal Conductivity Range: 2.0 – 10.0 W/m·K

Advantages:

● Excellent flowability to fill complex gaps;

● Self-healing and non-drying for long service life;

● Compatible with automated dispensing processes;

● Stable low thermal resistance under continuous heat cycles.

Drawbacks:

Higher material cost and requires specific storage and dispensing equipment.

Typical Applications: Data center GPU modules, automotive GPUs, industrial AI computing platforms.

Performance Comparison and Selection Guide

|

Type

|

Thermal Conductivity (W/m·K)

|

Flexibility

|

Stability

|

Electrical Insulation

|

Process Compatibility

|

Typical Applications

|

|

Thermal Pad

|

1.0 – 12.0

|

★★★★☆

|

★★★★★

|

Yes

|

Cutting / Mounting

|

GPU modules, VRAM

|

|

Thermal Grease

|

1.0 – 6.0

|

★★★★★

|

★★☆☆☆

|

No

|

Manual Coating

|

High-performance GPU

|

|

Thermal Gel

|

2.0 – 10.0

|

★★★★★

|

★★★★★

|

Optional

|

Automated Dispensing

|

Data center GPU, Automotive GPU

|

Selection Suggestions:

● For mass production and reliability, use thermal pads;

● For extreme performance and low resistance, use thermal grease;

● For automated assembly and long-term operation, use thermal gel.

The optimal solution balances thermal performance, process integration, and reliability through testing and system validation.

Conclusion: The Decisive Layer in GPU Thermal Design

GPU thermal management is an invisible yet decisive battlefield — and TIMs are the silent heroes.

They bridge the gap between silicon and metal, determining how efficiently heat escapes and how reliably systems perform.

As GPUs continue to evolve toward higher power density and compact architectures, the demand for high-conductivity, low-resistance, and automation-ready TIMs will keep rising.

Whether it’s flexible thermal pads, performance-driven thermal grease, or long-life thermal gels, effective material selection remains the key to unlocking GPU efficiency and reliability.

CN >

CN >