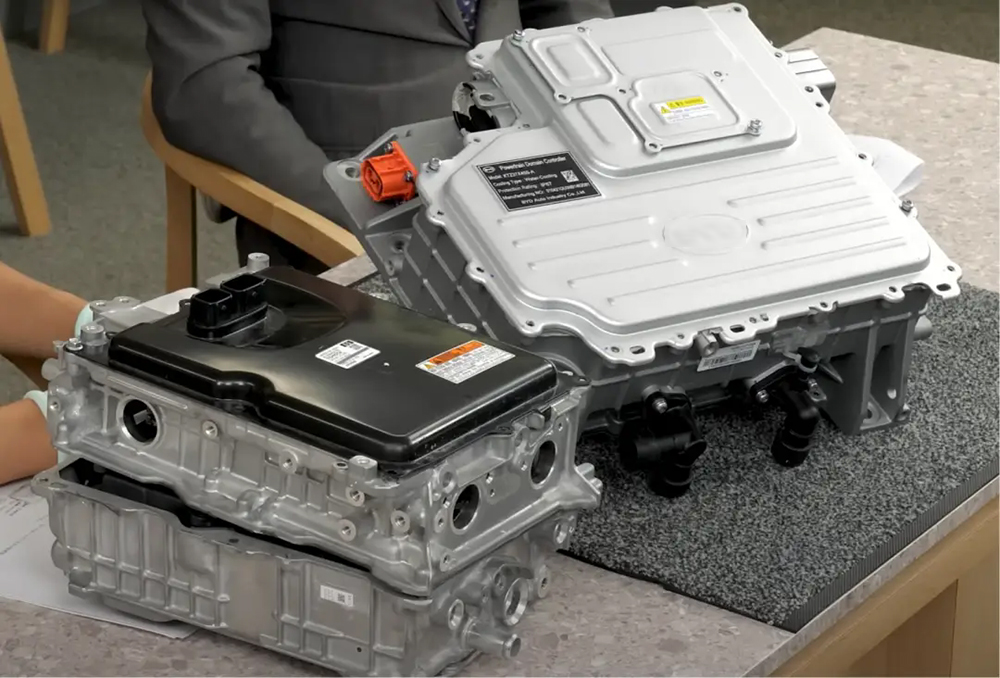

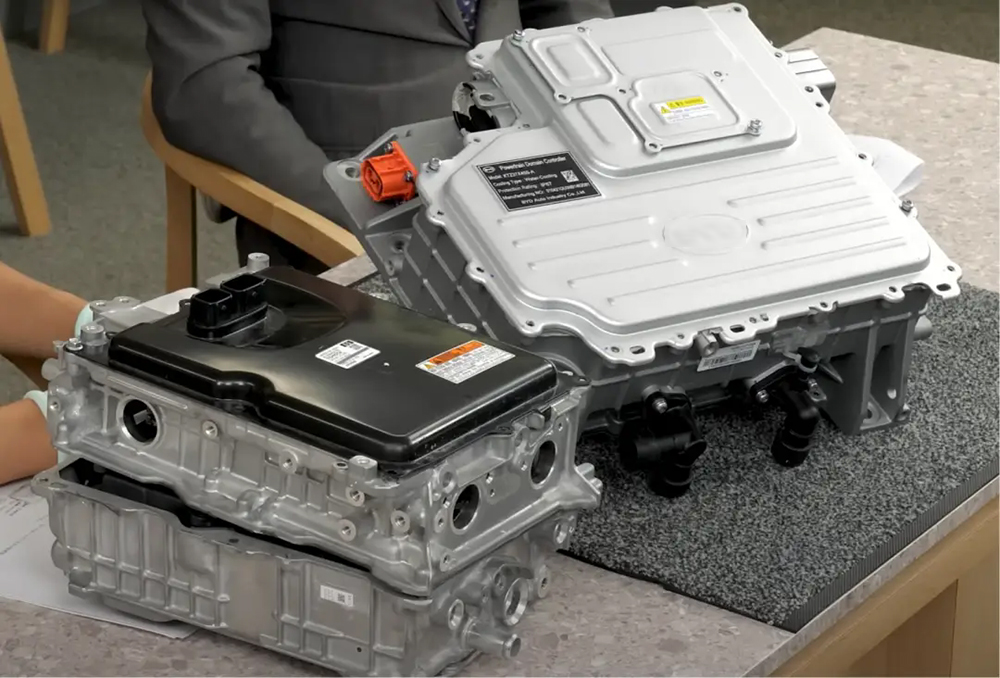

In the power electronics system of new energy vehicles (NEVs), the vehicle inverter serves as both the “brain” and the “heart” of power conversion. It transforms the DC power from the battery into AC power to drive the motor efficiently.

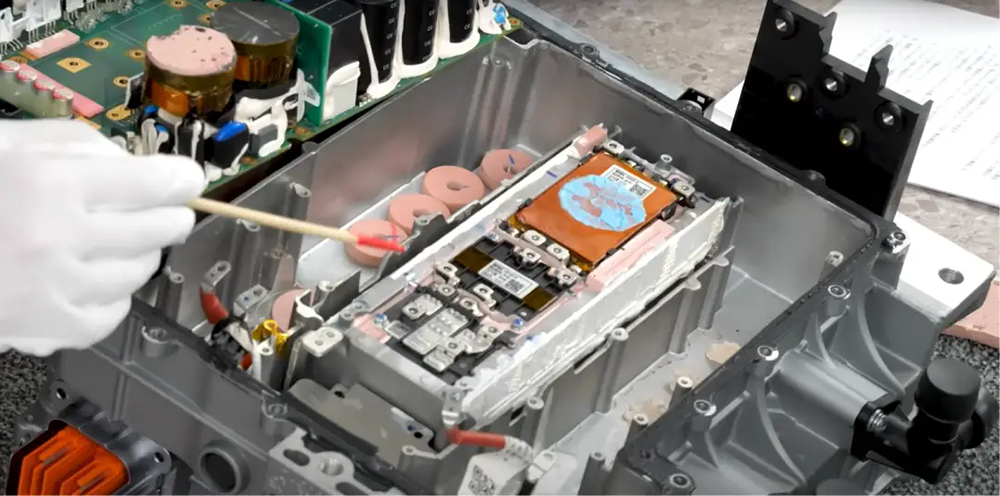

With continuous integration trends, the vehicle inverter now combines multiple functions, including the on-board charger (OBC), DC/DC converter, and battery management system (BMS) — forming a highly integrated electronic module responsible for energy conversion, charging control, and system management.

However, such high-density, multifunctional integration brings significant thermal management challenges. Power devices operate under high load and frequent start-stop conditions, generating substantial heat. Without efficient thermal dissipation, performance degrades and component lifespan shortens.

Selecting a high-performance thermal interface material (TIM) that ensures superior thermal conductivity, insulation, and long-term stability is therefore essential.

NFION NF150-150 thermal pad is designed precisely for these demanding automotive environments, offering exceptional thermal and mechanical performance.

Thermal Management Challenges in Vehicle Inverters

Vehicle inverters house multiple high-power components—MOSFETs, IGBTs, inductors, and capacitors—which generate heat during high-frequency switching. Due to limited internal space and restricted airflow, the thermal design must ensure high efficiency and electrical insulation simultaneously. Key challenges include:

● High heat flux density and rapid local temperature rise

● Repeated thermal cycles and mechanical stress

● Balancing insulation safety and thermal efficiency

Thus, the TIM must deliver high thermal conductivity, excellent compressibility, and long-term reliability to maintain performance stability in harsh automotive environments.

Precisely Matched for Automotive Conditions: Core Advantages of NF150-150

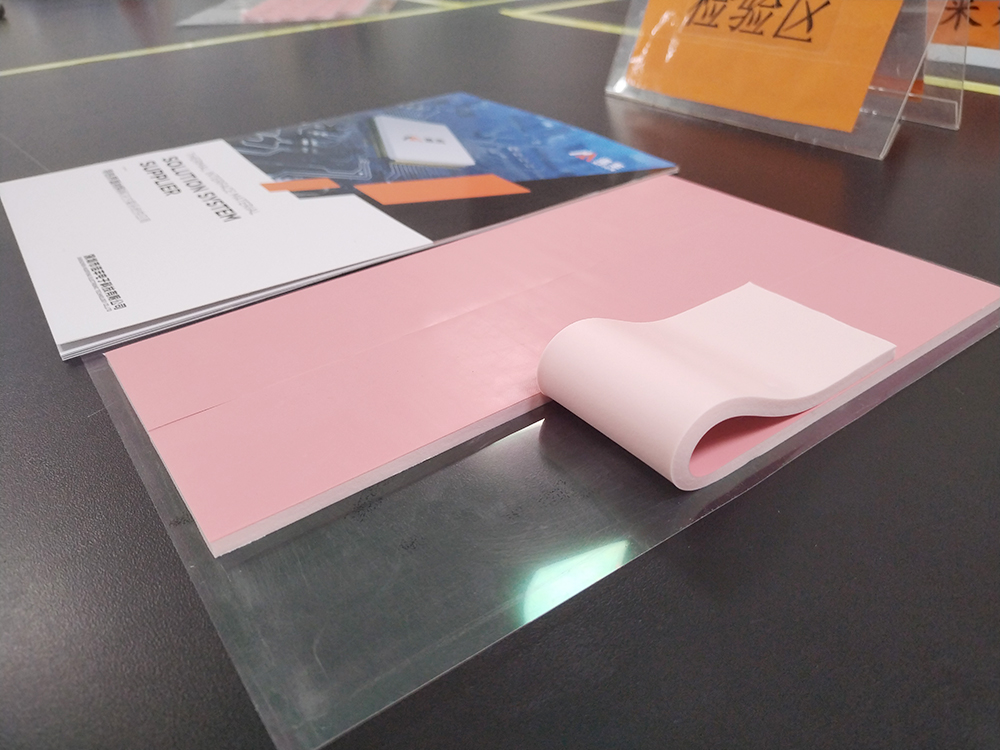

The NF150-150 thermal silicone pad is a high-performance TIM engineered to tackle high heat flux density and complex automotive thermal environments.

(1) Outstanding Thermal Conductivity

NF150-150 provides excellent thermal conductivity, enabling rapid heat transfer from power devices to heat sinks or metal housings. This ensures efficient temperature balance and prevents hot spots in compact inverter structures.

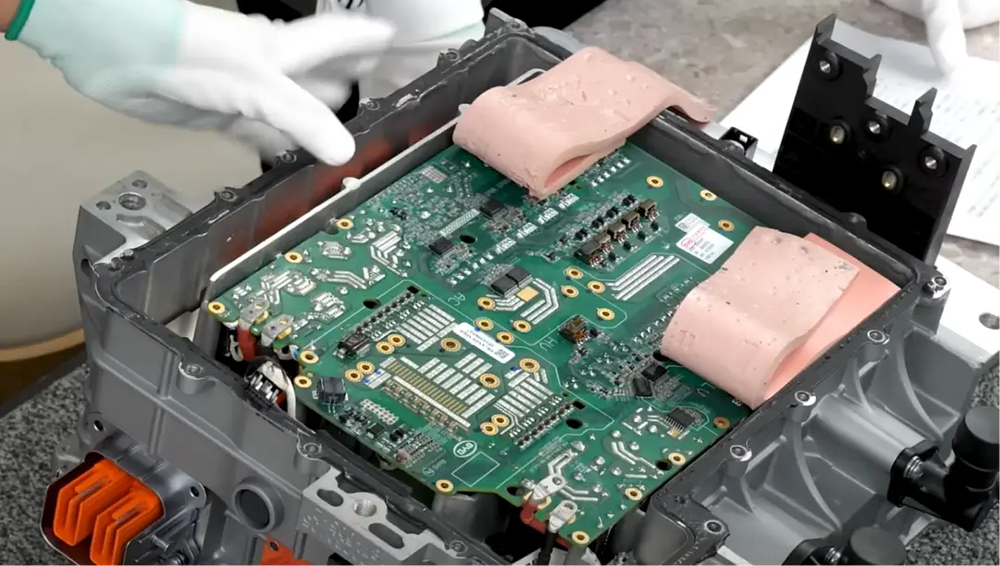

(2) Excellent Surface Compliance and Low Thermal Resistance

The silicone-based material is soft and highly compressible, allowing it to fill microscopic voids and eliminate air gaps — one of the worst thermal insulators. This ensures:

● Significantly reduced interface thermal resistance

● Enhanced thermal coupling between devices and heat sinks

Such low-resistance contact is vital for efficient heat dissipation in high-power inverter systems.

(3) Reliability and Stability in Harsh Environments

The NF150-150 demonstrates exceptional stability under wide temperature variations, vibration, and electrical stress:

● Temperature resistance: Stable performance from -40℃to +150℃, enduring multiple thermal cycles.

● Electrical insulation: With a dielectric strength >6KV, and optional silicone-coated fiberglass cloth, it enhances both mechanical durability and insulation safety — ideal for high-voltage compact designs.

● Vibration damping: The elastic property absorbs mechanical stress, protecting solder joints and power modules from vibration fatigue.

Typical Application Scenarios: Multi-Module Thermal Synergy

In integrated inverter architectures, the NF150-150 thermal pad can be applied across several key modules:

● Between IGBT power module and heat sink:

Rapid temperature transfer and uniform heat distribution, preventing localized overheating.

● Between DC/DC inductor and aluminum substrate:

Provides an efficient heat path and relieves thermal stress on solder joints and structural components.

● Between OBC rectifier module and metal housing:

Maintains controlled temperature rise during prolonged charging, ensuring system reliability.

● Between BMS control board and enclosure:

Offers both insulation and thermal conduction to keep monitoring chips stable.

This modular thermal design enables NF150-150 to optimize both localized heat dissipation and overall temperature balance, significantly improving system-wide thermal management efficiency.

Verified by Testing: Data Speaks for Itself

In validation tests conducted on a mainstream NEV inverter system, NF150-150 demonstrated remarkable improvements:

● Reduced key component temperature by 8–12°C

● Lowered total system thermal resistance by ~15%

● Extended thermal cycle lifespan by over 1.8×

These results confirm that NF150-150 not only enhances heat transfer efficiency but also mitigates thermal stress-induced fatigue, ensuring long-term reliability under high power and frequent operation cycles.

Conclusion

As the automotive industry advances toward higher integration, higher power density, and greater reliability, effective thermal management becomes a defining factor of system performance.

NFION NF150-150 thermal pad, with its superior thermal conductivity, insulation, compressibility, and environmental stability, stands as an ideal solution for thermal management in vehicle inverters and associated electronic modules.

It ensures efficient heat control, enhances safety, and supports the enduring reliability required by next-generation electric vehicles.

CN >

CN >