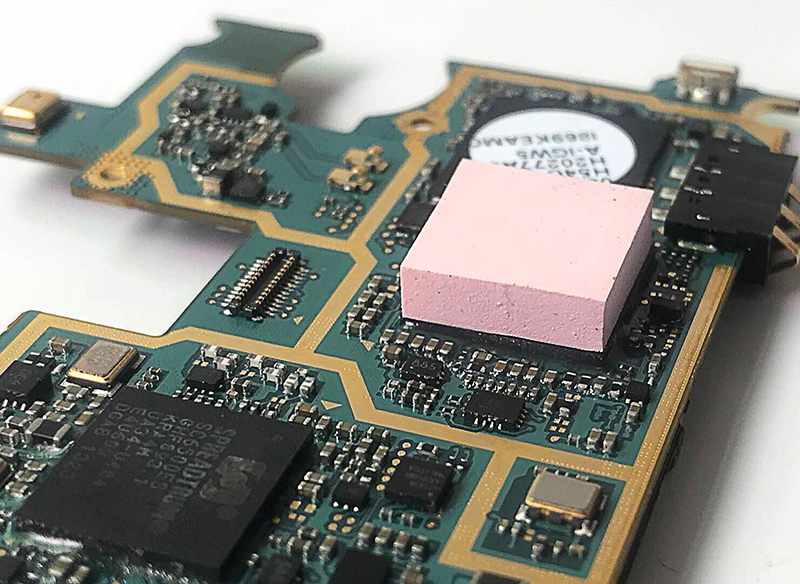

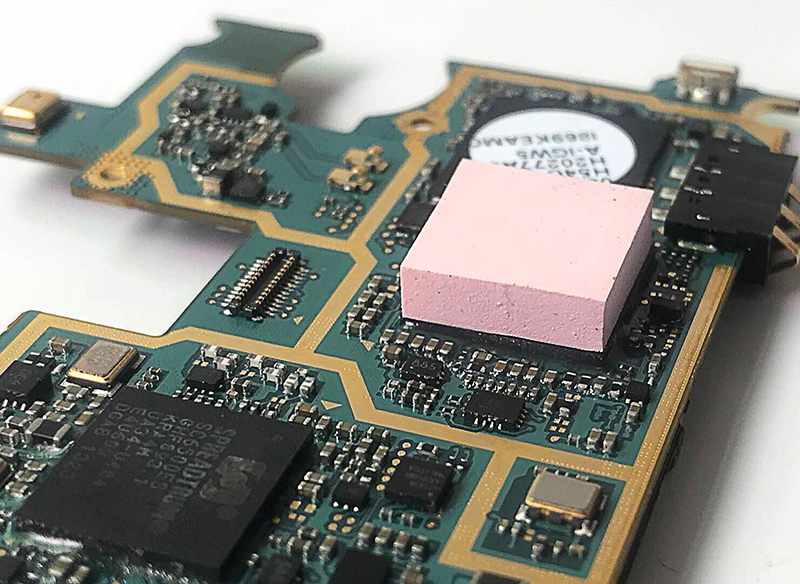

In the design of electronic device cooling solutions, the choice of thermal interface materials is crucial. From CPUs to GPUs, and various power modules, efficient heat transfer is key to ensuring stable device operation and extending their lifespan. Among numerous thermal materials, sil thermal pads are highly favored for their excellent thermal conductivity, electrical insulation, softness, and ease of handling. However, when selecting and applying sil thermal pads, beyond common parameters like thermal conductivity, thickness, and hardness, there's a vital yet often overlooked performance indicator: tensile strength. So, why should we pay special attention to the tensile strength of sil thermal pads?

Tensile Strength: The Unseen Guardian of "Toughness"

Tensile strength, in simple terms, is a material's ability to resist breaking when subjected to tensile load. For sil thermal pads, their tensile strength directly relates to the product's reliability and durability in practical applications. Imagine a sil thermal pad lacking sufficient tensile strength; it might "fail" at critical moments:

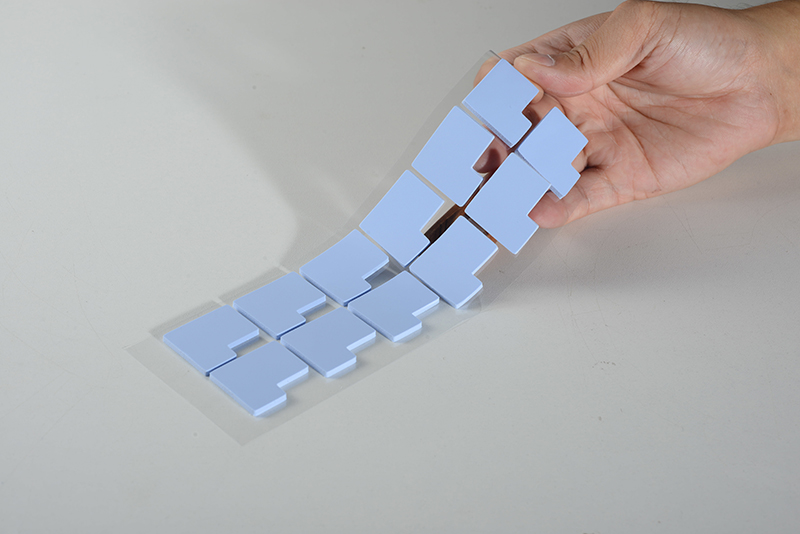

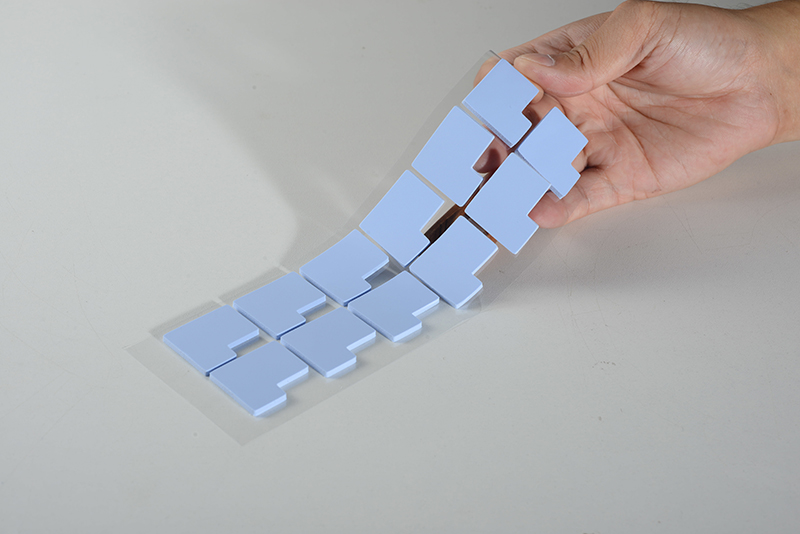

▪ Stress Challenges During Assembly: During the assembly of electronic products, sil thermal pads often need to be stretched, bent, or compressed to fit various installation gaps and structures. If the pad's tensile strength is insufficient, it can easily tear or damage during these operations, leading to installation failure or even compromising thermal performance. Especially on automated production lines, precise gripping and positioning by robotic arms require sil thermal pads to possess a certain degree of toughness to withstand instantaneous tensile forces.

▪ Thermal Expansion and Contraction During Long-term Operation: Electronic devices generate heat when operating and cool down when turned off. This cyclic thermal expansion and contraction can cause stress between different materials. As a gap-filling medium, sil thermal pads need to withstand minor displacements and deformations from two interfaces. If their tensile strength is inadequate, long-term stretch and compression cycles may lead to fatigue damage within the sil thermal pad, subsequently causing cracks or even detachment from the bonding surface, forming air gaps that severely affect thermal efficiency.

▪ Resistance to External Vibration and Impact: Some electronic devices, such as automotive electronics, industrial control equipment, or portable devices, may be subjected to vibration or impact during operation. Sil thermal pads, as elastomers connecting heating elements to heat sinks, need to absorb and buffer these mechanical stresses. High-tensile-strength sil thermal pads can better resist these external forces, preventing structural damage or thermal interface failure caused by vibration.

▪ Convenience for Rework and Maintenance: When a device requires rework or maintenance, the sil thermal pad sometimes needs to be peeled off its original position. If the sil thermal pad has high tensile strength, it can maintain material integrity when removed, making it less prone to shattering or leaving residues, thus facilitating subsequent cleaning and reinstallation. Conversely, low-tensile-strength sil thermal pads may fragment during removal, increasing rework difficulty.

How to Assess the Tensile Strength of Sil Thermal Pads?

Professional engineers typically refer to the material's physical property data sheet when selecting sil thermal pads, which clearly indicates the tensile strength value, usually in megapascals (MPa) or pounds per square inch (psi). Besides consulting data sheets, a comprehensive assessment can be made through:

▪ Supplier's Professional Reports: Reliable suppliers will provide detailed product specifications and test reports, including specific tensile strength values and test methods.

▪ Actual Sample Testing: In the early stages of a project, small-batch sample testing is an effective way to verify material performance. The tensile properties of sil thermal pads can be evaluated under conditions simulating real application environments.

▪ Consideration of Application Scenario Requirements: Set reasonable tensile strength requirements based on the end product's application environment, operating temperature range, vibration requirements, and assembly processes. For instance, for products that require frequent disassembly and reassembly or endure significant mechanical stress, sil thermal pads with higher tensile strength should be chosen.

Conclusion

The tensile strength of sil thermal pads is not an isolated parameter; it is closely linked to the material's toughness, durability, and reliability in practical applications. Ignoring tensile strength can lead to a series of potential problems, from reduced production efficiency to unstable product performance, and ultimately, failure. Therefore, in thermal design, in addition to focusing on overt indicators like thermal conductivity, we should also give adequate attention to the tensile strength of sil thermal pads. Choosing a sil thermal pad with appropriate tensile strength and reliable performance is a crucial step in ensuring the long-term stable operation of electronic devices and enhancing overall product competitiveness. Next time you're choosing a sil thermal pad, you might ask, "What about its tensile strength?"

CN >

CN >