Exhibition Background: Global Opportunities for New Energy Development

With the global energy structure undergoing profound changes, industries such as lithium batteries, hydrogen energy, and electric vehicles are rapidly emerging, and technological innovations across the entire value chain are accelerating. As one of the world’s most influential events in the battery industry, the 17th China International Battery Fair (CIBF2025) was grandly held in Shenzhen, China, from May 15 to 17, 2025. Thousands of battery manufacturers, material suppliers, equipment manufacturers, and end-application companies from around the world gathered to participate.

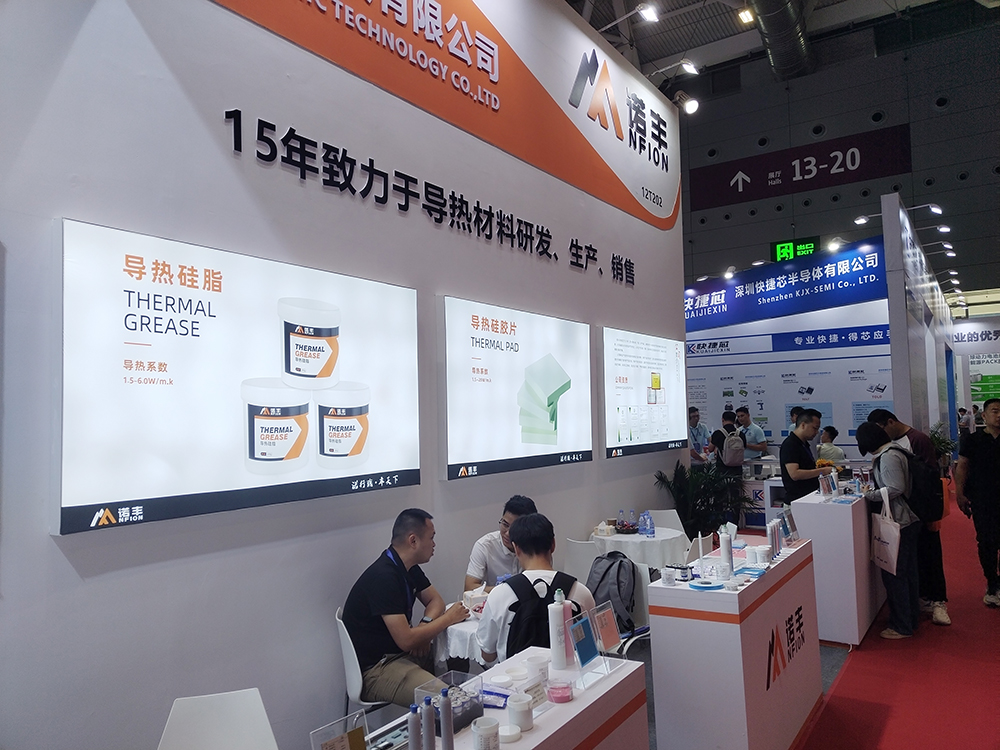

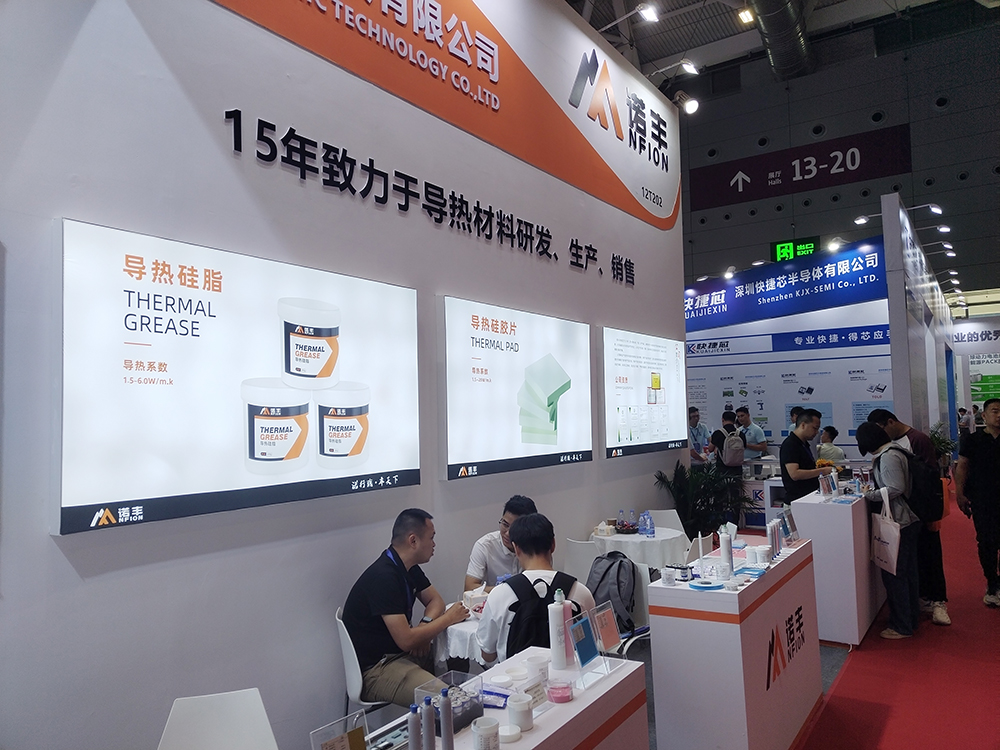

As a professional supplier in the field of new energy thermal management, NFION returned to the event with a new image as a “Comprehensive Thermal Management System Provider for New Energy,” showcasing its thermal interface, insulation, bonding, and potting material solutions across power batteries, energy storage systems, BMS control modules, and electric drive systems.

Industry Pain Points: More Complex and Demanding Thermal Management Needs

With the growing pursuit of fast charging, high power, and high integration in new energy vehicles, the power density of battery packs, electric drives, and energy storage modules has increased significantly. This has resulted in sharply rising heat loads and more severe thermal runaway risks. Achieving long-term system safety and stability while maintaining performance has become a key challenge across the entire new energy value chain.

NFION has been deeply engaged in the thermal management field for over a decade, accurately identifying thermal conduction, accumulation, and diffusion issues in new energy equipment operation. By focusing on critical application areas such as interface filling, structural bonding, module potting, and system insulation, NFION has built a diversified and multi-functional thermal management materials platform to meet comprehensive needs from component level to system level.

Star Product Matrix: Thermal + Insulation + Potting for Full Coverage

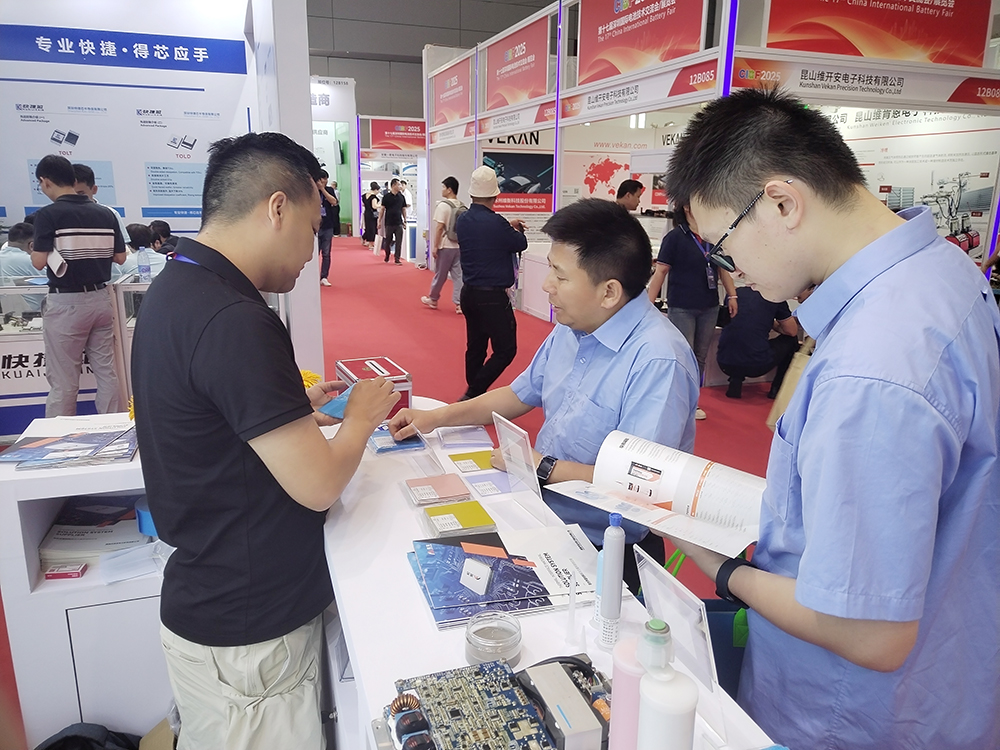

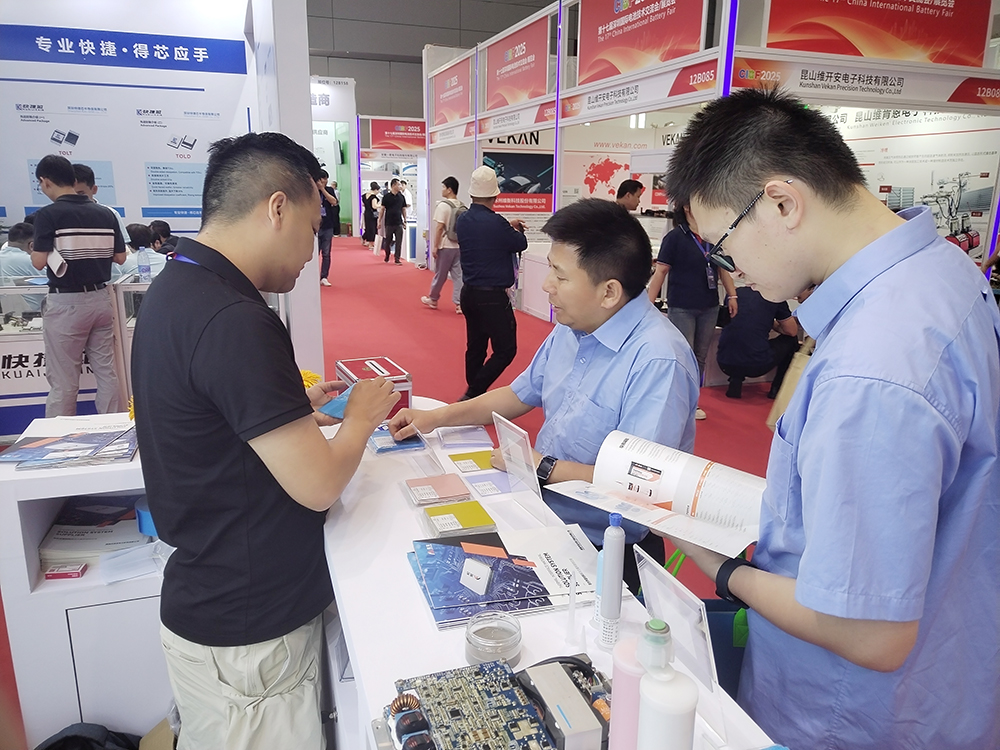

At CIBF2025, NFION presented a wide range of thermal management materials that drew the attention of many professional visitors:

Thermal Pads: Suitable for thermal interfaces in PACK structures, power modules, and inverters. Featuring excellent softness, compressibility, and electrical insulation. Thermal conductivity ranges from 1.0 to 12 W/m·K.

Thermal Gel: Ideal for gaps between cells and BMS heat dissipation. Offers high flowability, low stress, low thermal resistance, and is automation-friendly. Thermal conductivity reaches up to 10.0 W/m·K.

Thermal Adhesive: Used for structural bonding and heat conduction between battery modules and enclosures. High bonding strength and compatibility with various materials.

Thermal Potting Compound: Designed for encapsulating EV control units, electric drive systems, and energy storage controllers. Excellent flowability, insulation, and flame retardancy, with thermal conductivity options from 1.0 to 3.0 W/m·K.

Silicone Foam: Used for battery insulation, waterproof sealing (IP67/IP68), and cold plate support, helping prevent thermal runaway and circuit shorts.

Systematic Thermal Management: Integration of Materials, Simulation, and Processes

NFION doesn’t just provide individual materials—it delivers application-oriented system-level solutions. Leveraging a strong R&D platform, thermal simulation capabilities, and co-development experience, NFION offers end-to-end technical support, from thermal modeling and material selection to sample testing and mass production.

For instance, in battery pack thermal management, NFION solutions can include:

Filling cell gaps with thermal gel for rapid heat transfer;

Using thermal pads and adhesives to achieve three-in-one functions: heat dissipation, bonding, and insulation;

Potting the entire module area for sealed and long-life operation;

Adding insulation materials to block inter-cell heat diffusion and create a “thermal barrier layer” to enhance stability.

Through this “thermal + insulation + bonding + encapsulation” four-in-one design, NFION helps customers achieve more efficient thermal control, improved system reliability, and enhanced safety.

Advancing New Energy for a Greener Future

Today’s global new energy industry is entering a new phase where intelligence, efficiency, and safety are equally emphasized. As the cornerstone of system stability, thermal management materials and processes are becoming crucial drivers of industrial upgrades.

NFION remains committed to the principle of “Driving Thermal Management Upgrades with Material Innovation” and has successfully served leading clients including BYD, Xiaomi, Sunwoda, and Sungrow. Looking ahead, NFION will continue to strengthen its material R&D, intelligent manufacturing, and global market expansion, aiming to become a core force in the new energy thermal management sector.

Conclusion: Leading Green Transformation Through Thermal Management, NFION Powers Value Enhancement

Through the international platform of CIBF2025, NFION not only showcased its advanced technology in new energy thermal materials, but also redefined the industry’s new standards for “safety, reliability, and efficiency” from a system-wide perspective. Moving forward, NFION will continue collaborating with upstream and downstream partners to build a safe and efficient thermal control ecosystem and create a low-carbon, green future together.

CN >

CN >