In high-end fields such as electronics, automotive, and new energy, thermal performance directly determines product stability and lifespan. As a professional thermal conductive pad manufacturer, NFION Thermal is driven by technological innovation and rigorous quality management, continuously overcoming process bottlenecks to meet the growing market demand for efficient thermal management materials.

By leveraging the concept of "new quality productivity," NFION Thermal has successfully transitioned from traditional manufacturing to a new model characterized by high quality and efficiency, further cementing its benchmark status in the industry. This article will explore NFION Thermal's practices and achievements in the field of thermal conductive pads from the perspectives of advanced manufacturing, technological innovation, quality assurance, and customized services.

Advanced Manufacturing: Precision Crafting for High-Quality Products

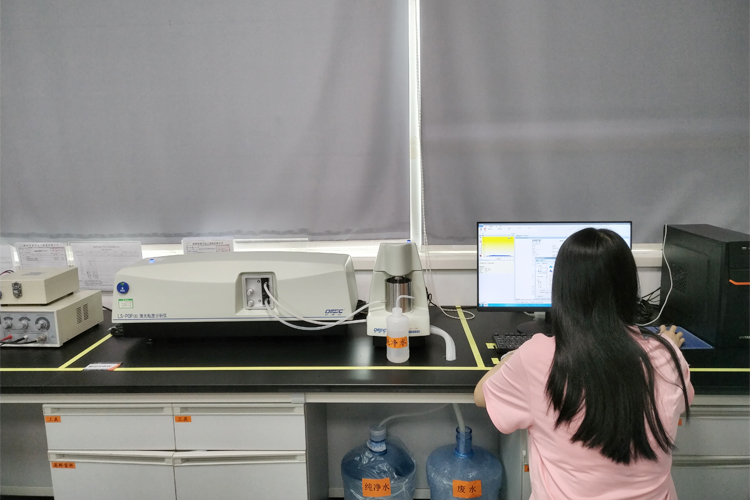

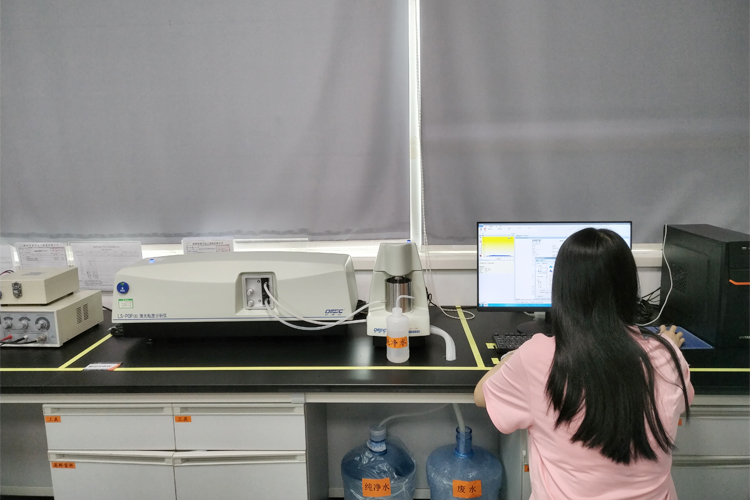

NFION Thermal relies on modern automated production lines and intelligent testing systems to achieve precise control throughout the entire production process, from raw material formulation to product delivery. The company has introduced high-precision dual planetary mixers, automatic compression molding systems, CNC automated cutting machines, and corona production lines. Through data-driven management and real-time monitoring, every batch of products meets strict technical specifications.

At the same time, the company continuously optimizes production processes, leveraging automated control systems to reduce human intervention, improve production efficiency, and enhance product consistency. This fully embodies the application of "new quality productivity" in manufacturing—achieving high quality and efficiency through technological upgrades and management innovation, ensuring NFION Thermal remains a market leader.

Technological Innovation: R&D-Driven Product Performance Upgrades

In product development, NFION Thermal continues to increase investment in technology, collaborating deeply with research institutions and universities at home and abroad. The focus is on breakthroughs in key areas such as high thermal conductivity, high-temperature resistance, and low stress.

▲ New Material Development: By optimizing the ratio of silicone matrix and high-performance thermal fillers, NFION has successfully developed next-generation thermal conductive pads with higher thermal conductivity and improved stability, meeting the cooling needs of high-power devices.

▲ Process Innovation: By adopting advanced mixing techniques and refined coating processes, NFION has significantly enhanced the thermal performance and durability of its products, ensuring excellent performance even in extreme environments.

▲ Intellectual Property Accumulation: The company has obtained multiple core patents, establishing a technological barrier centered on independent research and development, ensuring strong market competitiveness.

This approach, based on R&D and process innovation, not only enables continuous product upgrades but also injects sustainable vitality into the entire production system.

Strict Quality Control: Winning Market Trust Through Excellence

NFION Thermal adheres to a "quality-first" development philosophy, implementing a comprehensive internal quality control system.

▲ Comprehensive Testing: Each batch of products undergoes rigorous performance testing before leaving the factory, including thermal conductivity, temperature resistance, and adhesion strength, ensuring stability and reliability.

▲ Continuous Improvement: Based on customer feedback and market dynamics, NFION continuously optimizes its testing processes and technical standards to enhance product quality and achieve perfection in every detail.

▲ Customer Recognition: Thanks to stable product performance and outstanding technical service, NFION has established long-term partnerships with many renowned enterprises, becoming a key supplier in the automotive electronics, network communications, and new energy sectors.

By maintaining strict quality control while embracing new quality productivity, NFION has found the perfect balance between product excellence and production efficiency.

Customized Services: Meeting Diverse Market Needs with Flexibility

To address the specific thermal management needs of various industries, NFION Thermal provides one-stop solutions ranging from standard products to fully customized solutions.

▲ Product Customization: Whether for high-temperature applications in extreme environments or applications with strict electrical insulation requirements, NFION can adjust product formulations and processes according to customer needs, delivering tailored thermal management solutions.

▲ Technical Support: NFION has a dedicated pre-sales and after-sales service team that provides full-process support, from product selection and application design to on-site technical guidance. This helps clients quickly resolve thermal challenges and reduce system integration risks.

This customized service model exemplifies how "new quality productivity" is applied in the market, allowing for flexible adjustments in production and R&D strategies to better meet diverse customer needs.

NFION's Practical Case: Innovation Driving Industry Upgrades

In collaboration with BYD's new energy vehicle manufacturing division, NFION Thermal provided a customized thermal conductive pad solution to address the cooling needs of high-power electronic control units.

▲ Problem Analysis: The main challenge was heat dissipation issues in long-term high-temperature and high-load conditions, which could lead to uneven thermal distribution and excessive temperature rise.

▲ Technical Solution: By optimizing the composition and ratio of thermal fillers, NFION improved the heat transfer performance of the silicone matrix. Additionally, the refined coating process enhanced the overall thermal conductivity.

▲ Remarkable Results: After multiple trials and optimizations, the customized product successfully reduced equipment temperature, improved system stability, and significantly extended product lifespan. This helped the client save substantial maintenance costs and provided valuable experience for similar future projects.

This case demonstrates how NFION leverages the concept of new quality productivity, utilizing technological advancements and process optimizations to develop high-end products that meet stringent market requirements while maintaining a competitive edge.

Future Outlook: Leading Industry Transformation with New Quality Productivity

As demand for efficient thermal management materials continues to grow in sectors such as 5G, IoT, and new energy, NFION Thermal will continue driving technological innovation, deepening industry-academia collaborations, and expanding application fields. Looking ahead, the company plans to integrate intelligent manufacturing and digital factory concepts to advance from traditional production to a new quality productivity model.

By continuously improving production efficiency and product performance, NFION Thermal aims not only to establish itself as a global benchmark in the thermal conductive pad industry but also to lead the entire thermal management materials sector toward a new era of higher quality and efficiency.

Conclusion

NFION Thermal, with its robust manufacturing strength, continuous technological innovation, and strict quality control, provides customers with high-performance, high-reliability thermal conductive pad products. The emerging concept of new quality productivity has endowed the company with a new production approach and management mindset, enabling NFION Thermal to transition from traditional manufacturing to high-quality, high-efficiency productivity while continuously meeting market demands. In the future, leveraging this powerful momentum, the company will continue to make strides in thermal technology innovation and market expansion, leading the industry into a new era of higher standards.

CN >

CN >