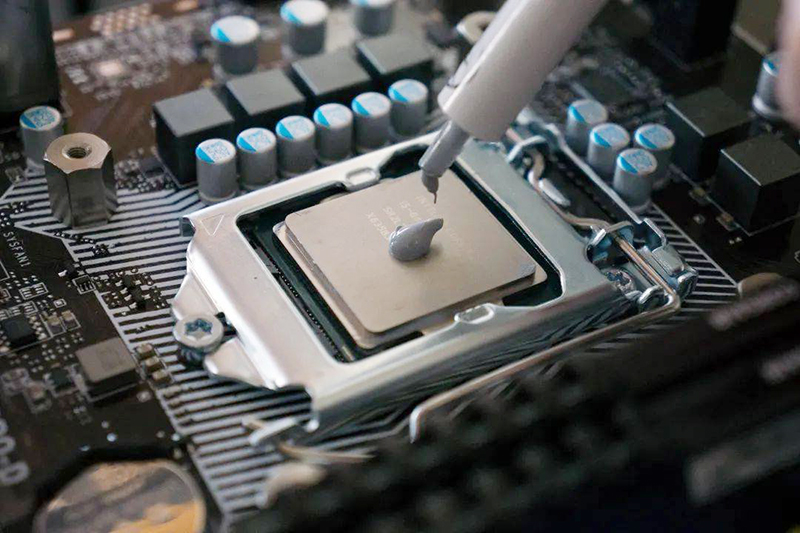

Overview of Thermal Grease

1. Superior Thermal Conductivity for Enhanced Heat Dissipation

2. Ultra-Low Thermal Resistance to Boost Heat Transfer Efficiency

3. Excellent Wettability to Ensure Tight Contact

4. Easy Application Adaptable to Various Scenarios

5. Good Temperature Resistance and Chemical Stability

6. Excellent Electrical Insulation Performance

7. Non-Curing Property for Easy Disassembly and Maintenance

8. Environmentally Friendly and Safe

Modern thermal greases are generally made from eco-friendly materials that comply with international standards such as RoHS.

● Non-Toxic and Harmless: High-quality thermal grease contains no harmful substances, posing no risk to human health or the environment.

9. Suitable for High-Power and High-Precision Electronic Devices

For high-power density chips, GPUs, IGBTs, and other electronic components, thermal grease offers a stable thermal management solution. It prevents performance degradation or component damage due to overheating, ensuring stable operation even under heavy loads.

Application Fields of Thermal Grease

Thanks to its excellent thermal performance and flexible application methods, thermal grease is widely used in:

1. Computers and Servers: Managing thermal interfaces between CPUs, GPUs, and heat sinks.

2. LED Lighting: Helping LED chips dissipate heat quickly to extend their lifespan.

3. Power Electronic Devices: Such as IGBT modules and MOSFETs, ensuring stable device operation.

4. New Energy Vehicles: Used in key areas like battery packs, charging modules, and onboard inverters for thermal management.

5. Communication Equipment: Including 5G base stations, switches, and power modules to reduce device temperatures and enhance reliability.

Conclusion

In summary, thermal grease provides an efficient and stable heat dissipation solution for electronic devices due to its outstanding thermal conductivity, ultra-low thermal resistance, and excellent wettability. It quickly transfers heat to lower device operating temperatures and extend lifespan. Its ease of application, non-curing property, and excellent temperature and chemical stability significantly enhance maintenance and replacement convenience. Furthermore, its excellent electrical insulation and eco-friendly attributes offer comprehensive protection for high-power, high-precision electronic devices, ensuring safety and reliability under heavy loads. Clearly, thermal grease holds broad application prospects in computers, LED lighting, power electronics, new energy vehicles, and communication equipment, and will continue to drive innovation in thermal management technology in the future.

CN >

CN >