Thermal grease, commonly referred to as thermal paste, is widely used as a thermal interface material (TIM) to enhance heat transfer between components such as processors and heatsinks in various electronic devices. While thermal grease offers several benefits, including improving heat dissipation and lowering component temperatures, it also has several disadvantages. NFION Thermal aims to provide a detailed, in-depth exploration of the drawbacks associated with thermal grease, helping readers better understand its limitations and potential issues in practical applications.

Limited Durability and Breakdown Over Time

One of the primary disadvantages of thermal grease is its tendency to degrade over time. The heat cycles in electronic components cause the thermal paste to break down, leading to a gradual reduction in its thermal conductivity. As the paste ages, it may dry out, harden, or even separate into its base components, leading to reduced performance. This degradation can result in overheating, as the interface between the processor and the heatsink becomes less effective, ultimately reducing the cooling efficiency of the system.

Furthermore, the drying or hardening of the thermal grease can make it challenging to remove or reapply, which is a significant issue during maintenance or upgrades. For systems that require periodic maintenance, the long-term durability of thermal grease is a critical consideration.

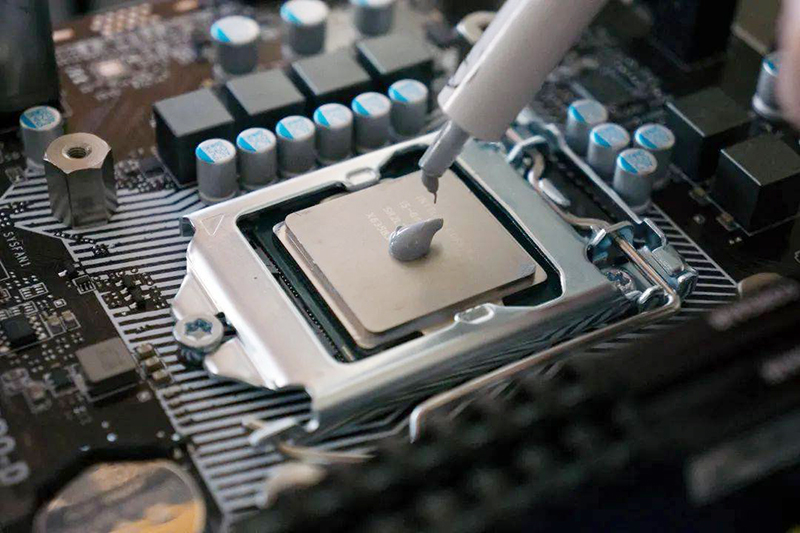

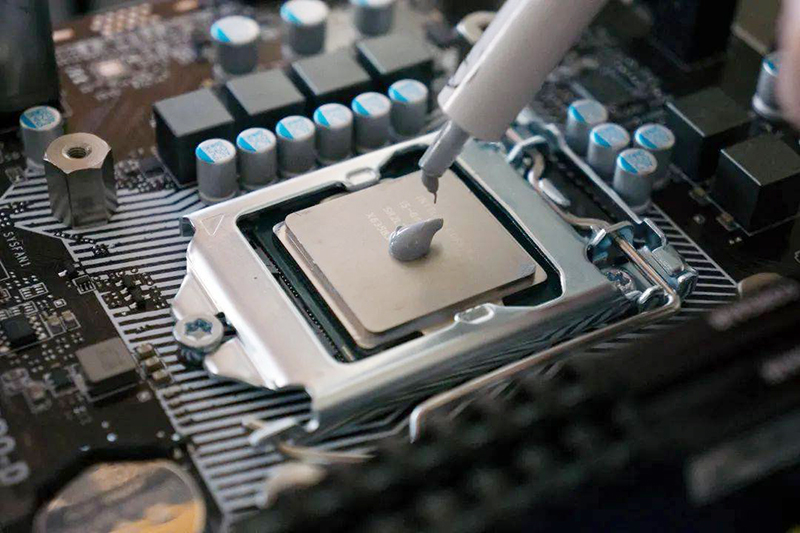

Messy Application Process

Another notable disadvantage of thermal grease is the complexity and messiness of the application process. When applying thermal paste, it is crucial to apply a thin, even layer to avoid excess paste, which can spill over the edges and cause electrical shorts or other issues. An improper application can result in poor heat transfer performance and even damage to the components due to the paste's potential to leak onto sensitive areas.

In addition, cleaning off old thermal paste can be a tedious task. The paste can be difficult to remove from both the CPU and heatsink surfaces, especially if it has hardened over time. Special solvents or wipes are often required to clean off the residue, adding another step to the maintenance process.

Potential for Uneven Distribution

While thermal grease is designed to improve the heat transfer between surfaces, achieving uniform coverage can be challenging. If the thermal paste is not applied evenly, some areas may have excessive paste, while others may have insufficient coverage. Inadequate paste in certain areas can result in poor thermal conduction, leading to higher operating temperatures and potentially causing thermal throttling or failure in critical components.

Achieving an even layer of thermal paste requires skill and precision, which may not always be possible for novice users. Even slight deviations in application can have a significant impact on the thermal performance of the system.

Conductivity and Potential for Short Circuits

Thermal grease is typically made from a mixture of silicone, metal oxides, or other compounds designed to improve heat conductivity. However, some types of thermal paste, particularly cheaper options, can be electrically conductive. If excess paste spills onto the motherboard or other electronic components, it can cause short circuits, leading to permanent damage or malfunction.

The risk of electrical conductivity is an important factor to consider when selecting thermal grease, especially when working with high-performance systems where the consequences of short-circuiting can be severe. This is why many high-end thermal pastes are non-conductive, but even then, careful application is still crucial to avoid mishaps.

Not Ideal for High-Pressure or High-Torque Applications

In systems where components are subjected to significant mechanical pressure or torque, such as high-performance processors or systems with intensive cooling setups, thermal grease may not be the most reliable option. In such conditions, the paste may be compressed or squeezed out from between the surfaces, reducing its effectiveness. The lack of a permanent bond between the processor and heatsink can lead to inconsistent thermal performance, especially under heavy usage.

For such high-stress applications, other thermal interface materials like thermal pads or phase change materials (PCMs) may provide better performance due to their more stable mechanical properties.

Incompatibility with Certain Materials

Not all thermal greases are compatible with every material or surface. Some types of thermal paste may not adhere well to certain materials like aluminum or plastic, potentially leading to inconsistent performance or issues with thermal conductivity. Additionally, the chemical composition of certain thermal pastes can react with certain metals, potentially causing corrosion or other types of damage.

When selecting thermal grease, it is essential to ensure compatibility with the specific materials used in the cooling system to prevent long-term damage.

Conclusion

Thermal grease is an essential component in many electronic devices to ensure efficient heat dissipation and prevent overheating. However, as outlined, it comes with several notable disadvantages that must be carefully considered. These include limited durability over time, the messy application process, challenges with achieving even distribution, the risk of short circuits, unsuitability for high-pressure applications, and material compatibility issues. While thermal paste remains a popular choice, users must weigh these drawbacks against its benefits and consider alternative thermal interface materials for specific applications.

Understanding these disadvantages will help users make more informed decisions about their thermal management solutions, ensuring optimal performance and longevity for their electronic systems.

CN >

CN >