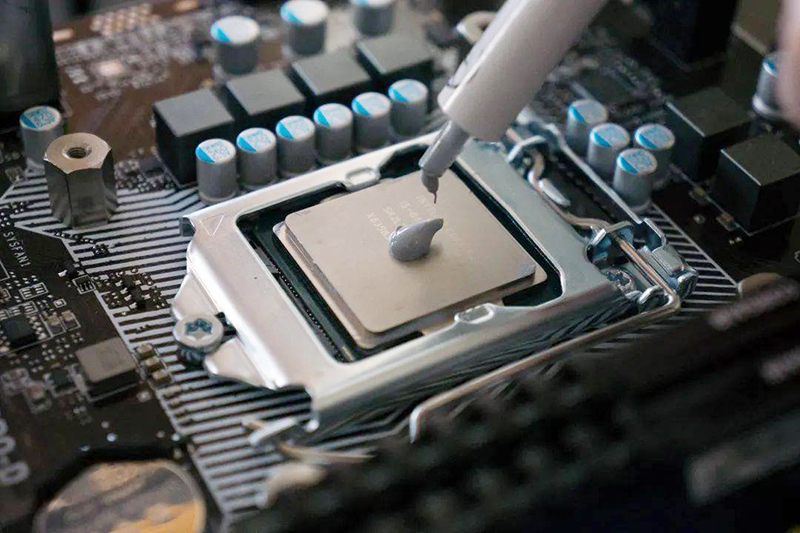

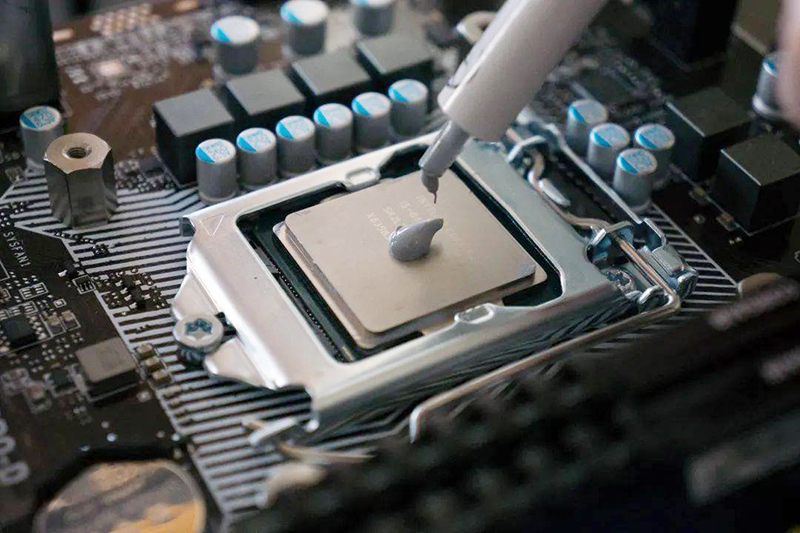

In electronic heat dissipation applications, thermal grease is widely used for its excellent thermal conductivity. Acting as a thermal interface material between heat-generating components and heat sinks, thermal grease effectively reduces contact thermal resistance and enhances device cooling efficiency. However, many users are concerned about whether thermal grease is electrically conductive—a factor crucial for safety and suitability around sensitive electronic components. Nfion Thermal will explore the composition, properties, and conductivity of thermal grease in depth to help readers better understand its characteristics and considerations for real-world applications.

Composition and Working Principle of Thermal Grease

Thermal grease is a thick, semi-fluid substance usually made by blending silicone oil (such as polydimethylsiloxane) with high thermal conductivity fillers like aluminum oxide, zinc oxide, or boron nitride. The primary function of thermal grease is to fill air gaps between heat-generating elements and heat sinks, creating a uniform thermal pathway that efficiently transfers heat to the heat sink. The main components of thermal grease are:

1. Base Material: Silicone oil (polydimethylsiloxane, PDMS), a non-polar compound known for its thermal stability and chemical inertness.

2. Thermal Conductive Fillers: Common fillers include aluminum oxide, zinc oxide, boron nitride, metal oxides, and carbon-based materials. These fillers improve thermal conductivity but are kept in small particles to ensure a uniform distribution within the base material and establish a conductive thermal network.

The thermal conductivity of thermal grease largely depends on the thermal properties and concentration of its fillers. Generally, thermal greases are designed to avoid conductive materials, as they are intended for heat conduction, not electrical conduction.

Conductivity Analysis of Thermal Grease

The electrical conductivity of thermal grease depends on the type and distribution of fillers within the base material. Most commercially available thermal greases use non-conductive fillers, such as aluminum oxide or zinc oxide, and thus, they are typically non-conductive. However, some special conductive thermal greases are available for applications requiring both conductivity and thermal performance.

1. Standard Thermal Grease: Non-Conductive

For standard thermal greases used in common heat dissipation needs, fillers like aluminum oxide, zinc oxide, and boron nitride are electrically insulating. These materials improve thermal performance while maintaining electrical insulation, reducing the risk of short circuits between electronic components. Non-conductive thermal greases are widely used in sensitive electronic devices such as CPUs, GPUs, and LED lighting, where they effectively manage heat without posing electrical safety risks.

2. Conductive Thermal Grease: Electrically Conductive

In specific applications, thermal grease may need both thermal and electrical conductivity. For example, electronic shielding or grounding applications may use thermal grease with conductive fillers such as silver powder, carbon nanotubes, or graphene. While these fillers provide conductivity, they are more costly, and the uniformity of filler distribution must be carefully managed to avoid short circuits or excessive conductivity.

III. Impact of Thermal Grease Conductivity on Applications

The electrical conductivity of thermal grease directly affects its applicability and safety in various scenarios. Below is a discussion of how conductivity influences real-world applications:

1. Heat Dissipation Applications: For most electronic heat dissipation cases, non-conductive thermal grease provides effective heat management without the risk of short circuits. Non-conductive thermal greases are the most common choice for applications such as CPUs and GPUs.

2. Grounding and Shielding Applications: In electronic shielding and grounding applications, conductive thermal grease can perform both heat and electrical conduction functions. For example, thermal grease containing graphene or silver powder can transfer heat and offer some electrical conductivity, suitable for electromagnetic shielding or current conduction applications.

3. High-Frequency or High-Voltage Environments: In high-frequency or high-voltage environments, conductive thermal grease must be used carefully to prevent short circuits. Non-conductive thermal grease is a safer choice, as it provides reliable insulation and minimizes the risk of arcing and overcurrent.

How to Select Suitable Thermal Grease

When selecting thermal grease, users should consider both thermal requirements and the electrical characteristics of their devices, assessing conductivity factors carefully. Here are some selection tips:

1. Thermal Performance: For common heat dissipation needs, non-conductive thermal grease with high thermal conductivity is sufficient for most heat sink and electronic component applications.

2. Electrical Insulation: For applications where electrical insulation is required, non-conductive thermal grease provides reliable insulation, reducing the risk of short circuits.

3. Conductivity Requirements: If conductive thermal grease is required, select products with uniformly distributed conductive fillers that provide stable conductivity. Also, ensure the concentration of conductive fillers aligns with device needs.

Conclusion

In conclusion, most thermal greases are non-conductive, making them safe for standard electronic component heat dissipation applications. However, conductive thermal greases with specific properties can be used for applications requiring both thermal and electrical conductivity. Users should balance conductivity and thermal performance according to device-specific requirements to ensure both efficient heat dissipation and electrical safety.

CN >

CN >