Enhancing Battery Safety and Performance with Silicone Thermal Pads in Energy Storage Systems

In modern energy storage systems, the rapid development of battery technology has provided strong support for renewable energy systems, electric vehicles, and smart grids. However, as the energy density of energy storage battery packs increases, heat dissipation has become a critical challenge. If heat dissipation is not properly managed, excessive internal temperatures within the battery pack can reduce system efficiency, shorten battery life, and even pose safety risks. To address this issue, silicone thermal pads have emerged as an effective thermal management material, widely used in energy storage battery packs.

Heat Dissipation Requirements and Challenges in Energy Storage Battery Packs

Energy storage battery packs are typically composed of multiple individual cells connected in series or parallel, with each cell generating heat during charging and discharging. As the capacity of the battery pack increases, the heat generated by individual cells also increases, making the overall heat dissipation more complex. If heat is unevenly distributed or localized overheating occurs, it may lead to thermal runaway, causing system failures or even severe accidents.

The heat dissipation requirements can be summarized as follows:

1. Uniform Heat Distribution: Ensuring balanced temperatures across all battery cells to avoid localized overheating.

2. Efficient Heat Dissipation Pathways: Providing an efficient and stable pathway for heat generated inside the battery to dissipate.

3. Lightweight and Space Optimization: Achieving effective thermal management within limited space while maintaining the lightweight and compact design of the battery pack.

These demands place high requirements on the performance of thermal materials. Traditional cooling methods, such as air and liquid cooling, though effective, may not be practical in certain applications. Silicone thermal pads, with their unique properties, play an increasingly important role in thermal management.

Properties and Advantages of Silicone Thermal Pads

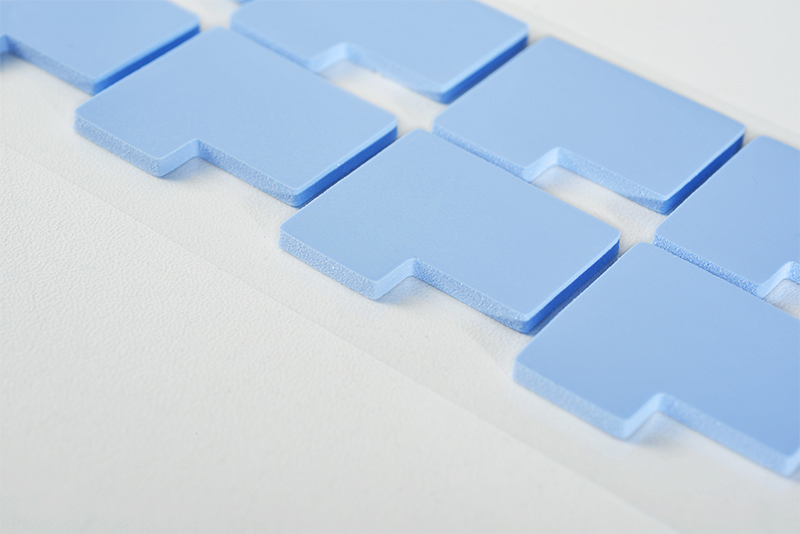

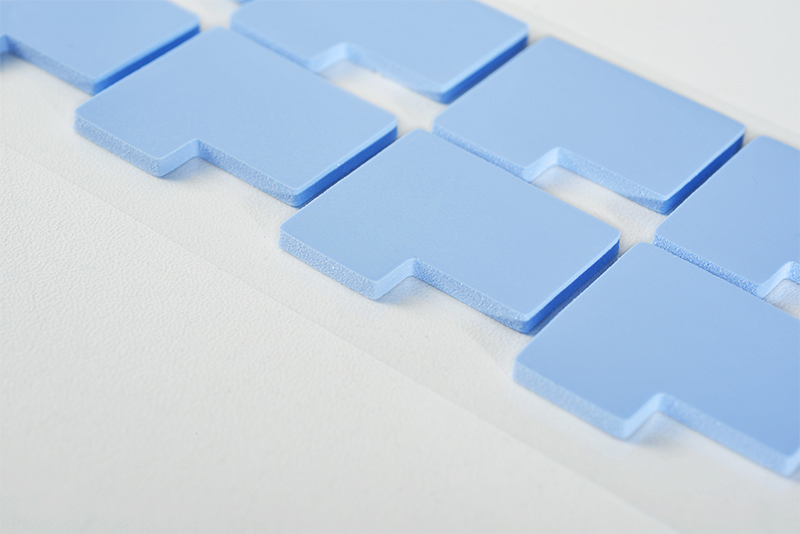

Silicone thermal pads are composite materials based on silicone rubber, filled with thermal conductive fillers. Their excellent thermal conductivity and flexibility make them an ideal choice for thermal management in energy storage battery packs. The key advantages are as follows:

1. High Thermal Conductivity: Silicone thermal pads generally exhibit high thermal conductivity (1-5 W/m·K), enabling rapid heat transfer within the battery pack to prevent localized overheating and improve overall thermal efficiency.

2. Good Flexibility and Filling Capability: The flexibility of silicone thermal pads allows them to effectively fill gaps within the battery pack, increasing the thermal contact area and reducing thermal resistance. This is especially useful in accommodating irregular shapes within complex battery pack structures.

3. Electrical Insulation: As an insulating material, silicone thermal pads offer excellent electrical insulation, preventing safety hazards from poor electrical contact or short circuits within the battery pack.

4. Vibration Resistance and Durability: During operation, battery packs may be subjected to mechanical vibrations and environmental shocks. Silicone thermal pads not only provide vibration absorption but also maintain physical stability and durability at high temperatures.

5. Lightweight and Design Flexibility: The lightweight design of silicone thermal pads reduces the overall weight of the battery pack, and their flexibility allows for customization in different shapes and thicknesses to optimize the thermal management layout.

Applications of Silicone Thermal Pads in Energy Storage Battery Packs

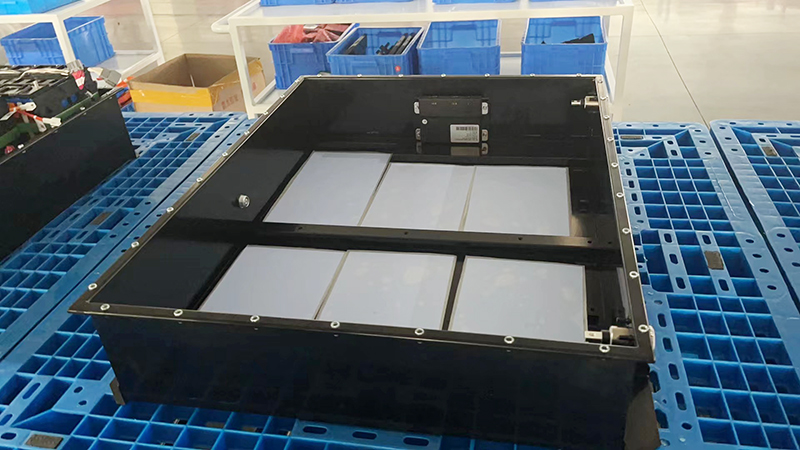

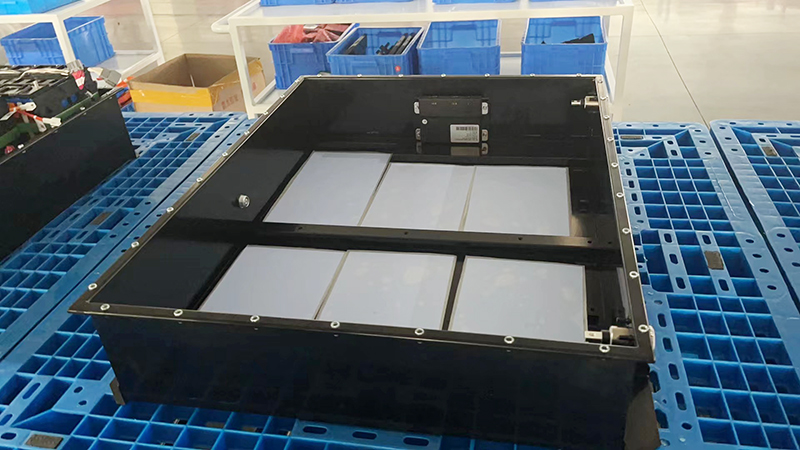

1. Thermal Management Between Battery Cells and Heat Sinks

In battery pack design, managing the thermal interface between battery cells and heat sinks (such as metal heat sinks or liquid cooling plates) is critical to achieving efficient heat dissipation. Silicone thermal pads act as thermal interface materials (TIMs), filling the micro-gaps between cells and heat sinks to lower thermal resistance and enhance heat dissipation. Their flexibility also absorbs the stress caused by thermal expansion and contraction, preventing structural damage to the battery pack during long-term operation.

2. Thermal Isolation Between Battery Modules

Energy storage battery packs typically consist of multiple modules, and large temperature differences between these modules can lead to thermal runaway. Adding silicone thermal pads between modules can not only effectively transfer heat and prevent overheating but also achieve thermal isolation, ensuring uniform heat distribution across the entire battery pack.

3. Overall Thermal Design of the Battery Pack

Beyond serving as a thermal interface material, silicone thermal pads can also be used as elements of the entire thermal design of the battery pack. For instance, applying silicone thermal pads to the inner surface of the battery pack housing can quickly transfer internal heat to external cooling systems. Additionally, silicone thermal pads can be combined with other cooling components (such as aluminum heat sinks or liquid cooling plates) to further improve overall heat dissipation performance.

4. Future Trends in Silicone Thermal Pads for Energy Storage Systems

As energy storage technology continues to advance, silicone thermal pads are evolving in terms of performance and application areas. In the future, they will develop in the following directions:

1. Higher Thermal Performance: By introducing new fillers and manufacturing processes, silicone thermal pads will achieve higher thermal conductivity to meet the heat dissipation needs of higher energy density battery packs.

2. Smart Thermal Management Materials: Combining with smart sensing technology, silicone thermal pads will be developed to monitor and adjust temperatures in real-time, achieving more intelligent thermal management.

3. Environmental Sustainability: More emphasis will be placed on environmental protection and sustainability in material selection and production processes, reducing environmental impact and promoting greener energy storage systems.

Conclusion

As an important part of heat dissipation solutions in energy storage battery packs, silicone thermal pads provide excellent thermal conductivity, flexibility, electrical insulation, and design flexibility to effectively solve internal heat management challenges. With the continuous progress of energy storage technology, silicone thermal pads will play an increasingly important role in future thermal management applications, ensuring the safety, reliability, and efficiency of energy storage systems.

CN >

CN >