As modern electronic devices trend towards higher performance and miniaturization, thermal management of battery cells has become a critical challenge for design engineers. During operation, battery cells generate significant amounts of heat, and without timely and effective dissipation, this heat can lead to overheating, negatively impacting performance, lifespan, and even posing safety risks. Thermal insulation pads, as a crucial thermal management material, play a vital role in battery cell thermal management due to their excellent thermal conductivity and flexibility.

Basic Characteristics of Thermal Insulation Pads

Thermal insulation pads are composed of silicone rubber and thermal conductive fillers, providing good thermal conductivity, flexibility, and insulation. Common thermal conductive fillers include aluminum oxide, boron nitride, and zinc oxide, which significantly enhance the thermal conductivity of the insulation pads. Additionally, these pads exhibit high-temperature resistance, compressibility, and anti-aging properties, enabling them to perform consistently and reliably in a variety of complex working environments over extended periods.

The Mechanisms of Thermal Insulation Pads in Battery Cells

● Heat Conduction

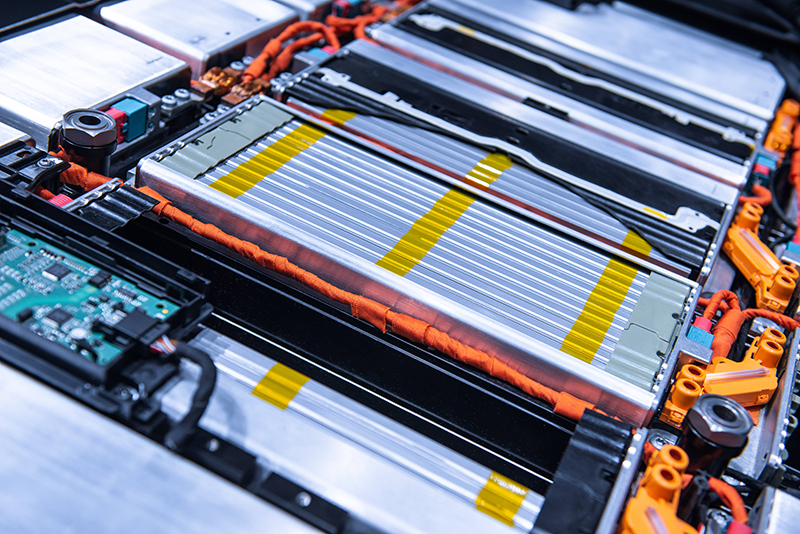

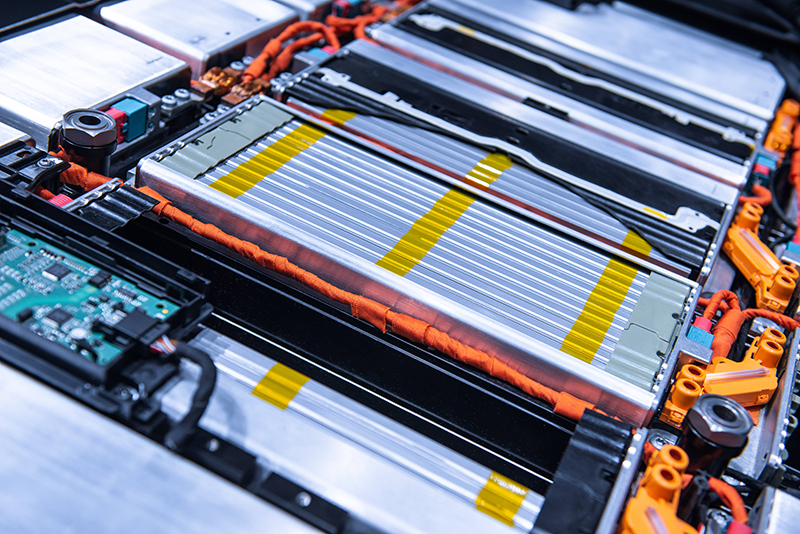

During operation, battery cells generate heat that needs to be transferred away through a medium to prevent excessive temperatures that could cause electrochemical imbalance. Thermal insulation pads, with their high thermal conductivity, can efficiently transfer heat generated by the battery cells to heat sinks or metal casings, effectively lowering the operating temperature of the cells and thereby maintaining their stable performance.

● Cushioning and Filling in Thermal Management

Thermal insulation pads not only offer good thermal conductivity but also serve as cushioning and filling materials between battery cells and heat sinks due to their softness. The surfaces of battery cells and heat sinks may have certain roughness or irregularities, and direct contact may result in insufficient contact area, thus affecting heat dissipation. Insulation pads fill these microscopic gaps, increasing the contact area and improving heat transfer efficiency. Additionally, they cushion external pressures, protecting the battery cells from mechanical stress.

● Electrical Insulation

In addition to thermal conductivity, safety must also be considered in battery cell thermal management. Thermal insulation pads provide excellent electrical insulation, which is particularly important in densely integrated electronic devices. This property effectively prevents electrical short circuits between battery cells or between cells and other electronic components, ensuring safe operation of the device.

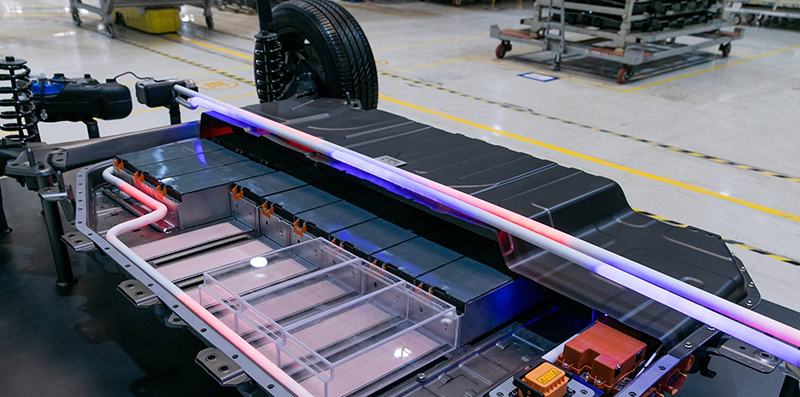

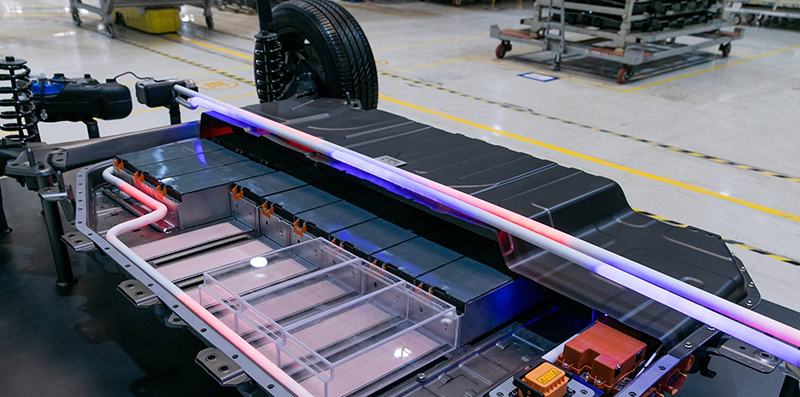

Applications of Thermal Insulation Pads in Battery Cells

In the thermal management of battery cells, thermal insulation pads are typically applied in the following areas:

● Between the Battery Cell and Casing: Acting as a thermal interface material between the battery cell and the casing, these pads enhance the efficiency of heat transfer from the cell to the casing.

● Between the Battery Cell and Heat Sink: Using thermal insulation pads between the battery cell and the heat sink ensures rapid transfer of heat to the heat dissipation system.

● Within Battery Modules: Within battery modules, these pads can connect different cells, ensuring uniform heat distribution.

Advantages of Thermal Insulation Pads

● Efficient Heat Dissipation, Prolonging Battery Life

By using thermal insulation pads, battery cells can operate at lower temperatures, thereby extending their lifespan. Research indicates that for every 10°C reduction in battery temperature, the lifespan can double. Therefore, efficient thermal management is crucial for extending battery life.

● Enhanced Device Performance and Stability

Excessive temperatures can lead to performance degradation of battery cells and may even cause thermal runaway, affecting device stability. Thermal insulation pads efficiently dissipate heat while maintaining the operating temperature of the cells within an ideal range, thereby enhancing overall device performance and reliability.

● Reducing Device Size and Supporting Design Optimization

The high thermal management capability of insulation pads minimizes the need for additional heat dissipation structures, significantly reducing device size and supporting the miniaturization of modern electronic devices. This not only improves device portability but also allows for optimized internal spatial arrangements.

Optimization of Thermal Insulation Pad Performance

To further enhance the effectiveness of thermal insulation pads in battery cell heat dissipation, researchers and engineers are continually exploring and optimizing their performance:

● Selection of Thermal Conductive Fillers: By choosing different types and ratios of thermal conductive fillers, the thermal conductivity of insulation pads can be optimized.

● Improvement of Base Materials: Enhancing the formulation of the silicone rubber base material can improve its temperature resistance and durability.

● Customization of Thickness and Shape: Customizing the thickness and shape of the insulation pads based on the thermal dissipation needs of the battery cells ensures compatibility with various application scenarios.

Conclusion

Thermal insulation pads play an indispensable role in the thermal management of battery cells. Their excellent thermal conductivity, flexibility, and electrical insulation properties make them essential materials in modern electronic device thermal management. By effectively utilizing thermal insulation pads, engineers can significantly improve the heat dissipation efficiency of battery cells, extend their lifespan, and enhance the performance and safety of devices. As the performance demands of electronic devices continue to rise, the application of thermal insulation pads in battery cells will become increasingly widespread, and their importance will only grow.

CN >

CN >