Why Do Thermal Conductive Pads Degrade?

Author:NFION

Date:2025-03-27 17:26:15

Introduction

Thermal conductive pads are essential in electronic device thermal management and are widely used across various electronic products. However, many users notice that the cooling performance of these pads declines over time, leading to concerns about their long-term effectiveness. What exactly causes the degradation of thermal conductive pads? What scientific principles govern this process? This article unveils the truth behind thermal conductive pad degradation, helping you better understand how this material performs and changes over time.

Basic Principles of Thermal Conductive Pads

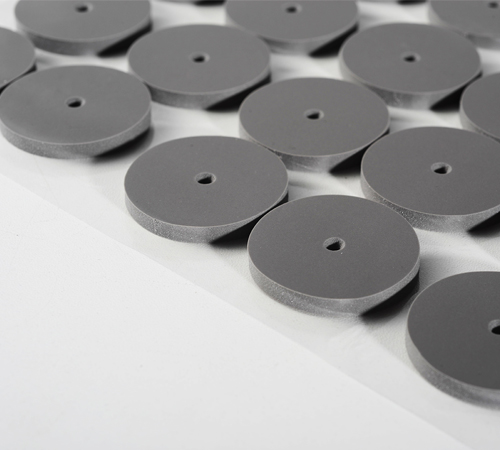

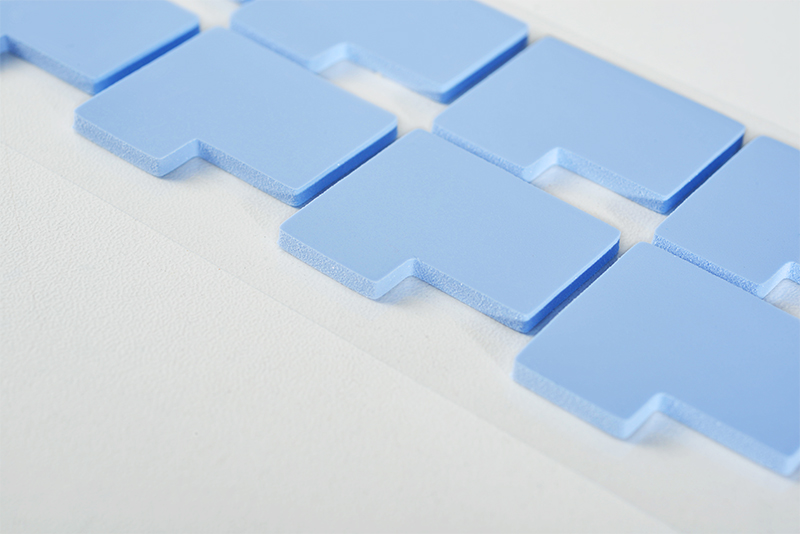

Before diving into the reasons for degradation, we must first understand the fundamental working principles of thermal conductive pads. These materials act as thermal interface materials (TIMs) placed between electronic components and heat sinks. They fill microscopic surface irregularities, enhancing heat transfer and reducing device operating temperatures.

The core component of these pads is silicone, which offers good thermal conductivity and flexibility, enabling it to conform to different surfaces and ensure effective heat dissipation.

Causes of Thermal Conductive Pad Degradation

1. Thermal Cycling and Aging

Thermal conductive pads undergo frequent temperature fluctuations as electronic devices operate. These temperature changes cause expansion and contraction, accelerating the aging process of the pad’s internal structure. Over time, molecular changes occur in the silicone, leading to a reduction in thermal conductivity and overall cooling performance.

2. Pressure Changes and Seal Failure

During long-term use, thermal conductive pads experience pressure variations due to continuous device operation. These fluctuations may reduce the pad’s ability to maintain tight contact between surfaces, leading to thermal interface degradation. When heat transfer efficiency decreases due to poor contact, overall cooling performance deteriorates.

3. Moisture Absorption and Oxidation

Thermal conductive pads can absorb moisture from the environment, causing swelling and changes in their physical properties. Additionally, moisture exposure can accelerate oxidation, further degrading the material’s thermal conductivity. The combined effects of moisture and oxygen contribute significantly to the performance decline of thermal conductive pads.

The Impact of Thermal Conductive Pad Degradation

The degradation of thermal conductive pads directly affects the cooling efficiency of electronic devices. As thermal conductivity decreases, devices may experience overheating, compromising their stability and lifespan. In industries such as high-performance computing, servers, and telecommunications, inadequate heat dissipation can lead to system failures or hardware damage.

How to Slow Down Thermal Conductive Pad Degradation

1. Choose High-Quality Materials

Selecting high-quality thermal conductive pads is crucial for minimizing degradation. Premium materials offer better resistance to temperature, pressure, and oxidation, significantly extending the product's lifespan.

2. Optimize the Operating Environment

Avoid exposing devices to extreme temperatures or humidity levels. Maintaining an optimal operating temperature can slow down the degradation process. Additionally, regularly inspecting and cleaning the cooling system ensures consistent performance and prolongs the pad’s effectiveness.

3. Regular Replacement of Thermal Materials

Despite preventive measures, thermal conductive pads will inevitably degrade over time. Periodic replacement is essential for maintaining long-term system stability. In high-load applications, replacing the pads restores optimal cooling performance and prevents hardware failure due to overheating.

Conclusion

Thermal conductive pad degradation is an unavoidable process, but understanding the scientific principles behind it allows for better prevention and management. Choosing high-quality materials, optimizing working environments, and scheduling timely replacements are key strategies for prolonging the lifespan of thermal conductive pads and ensuring device stability.

With proper maintenance and careful material selection, you can slow down thermal conductive pad degradation, maintain high-efficiency cooling performance, and ensure the reliable operation of your electronic devices.

CN >

CN >