Introduction

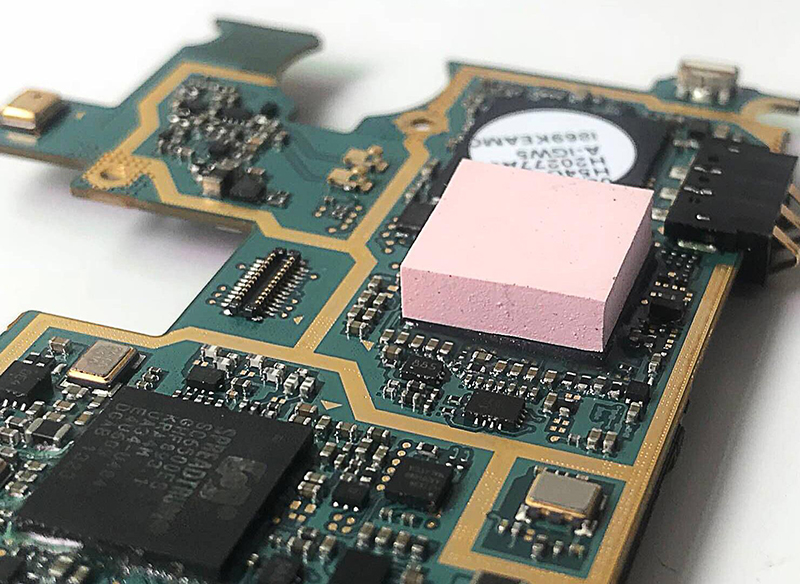

In electronic device thermal management, thermal conductive pads are widely used for heat transfer between high-power components such as IC chips, power modules, LED lighting, and communication equipment due to their excellent thermal conductivity and soft filling properties. However, in long-term use or high-temperature environments, some thermal conductive pads may exhibit oil bleeding, raising concerns about whether it affects circuit safety or even damages devices. This article will analyze the causes of oil bleeding in thermal conductive pads, its possible impact, and how to select low-bleeding, high-quality products to minimize potential risks.

1. Causes of Oil Bleeding in Thermal Conductive Pads

1.1 Definition of Oil Bleeding

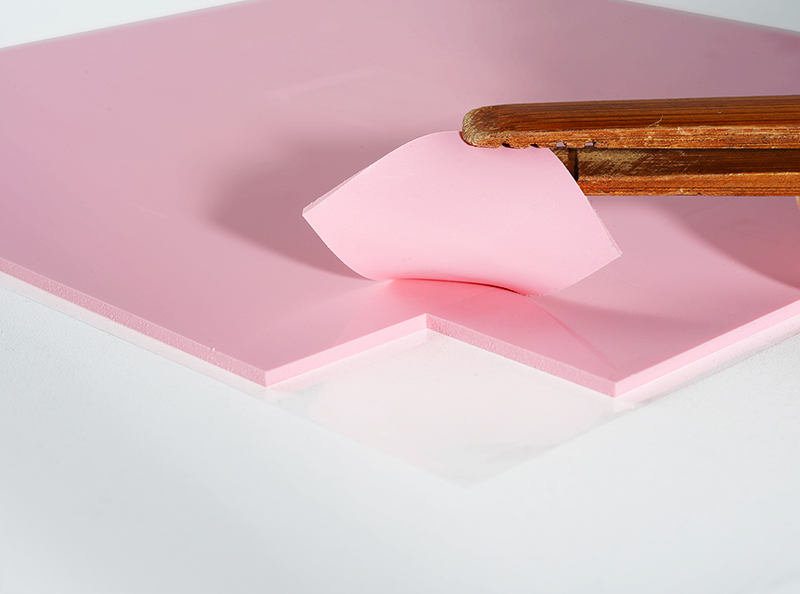

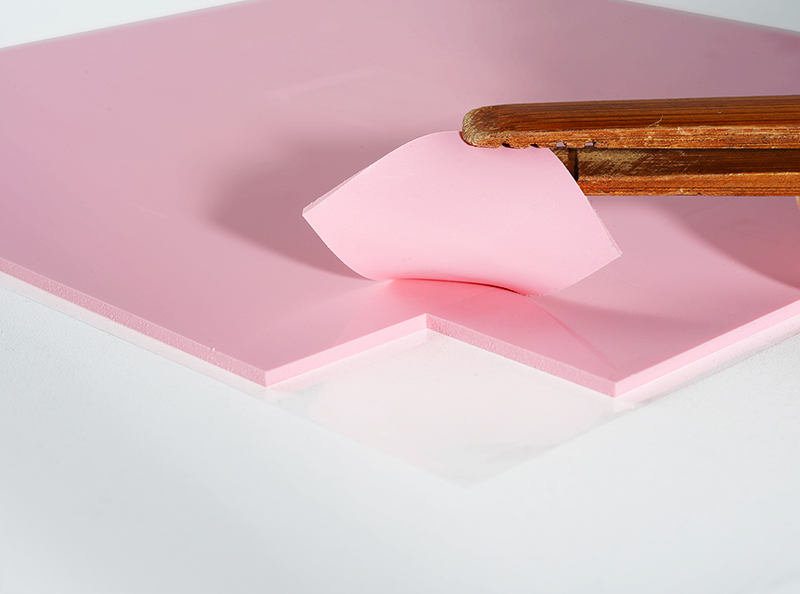

Oil bleeding in thermal conductive pads refers to the exudation of low-molecular-weight silicone oil from the material over time or under high temperatures, forming an oil film or oil droplets. While this phenomenon may affect product performance, whether it can damage circuits requires further analysis.

1.2 Main Factors Leading to Oil Bleeding

(1) Material Composition

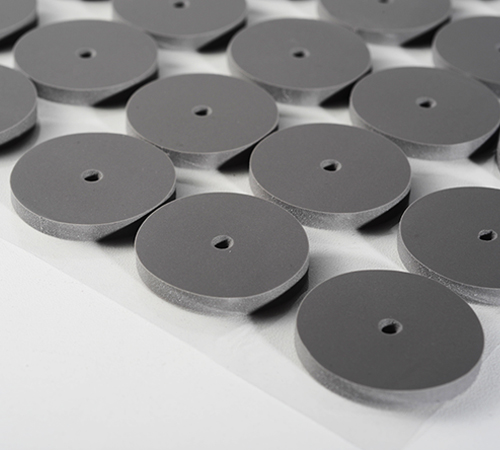

● The core components of thermal conductive pads are silicone rubber and thermal fillers (such as aluminum oxide, boron nitride, and magnesium oxide).

● If the silicone rubber contains excessive low-molecular-weight silicone oil or has insufficient cross-linking, silicone oil is more likely to exude.

(2) Manufacturing Process

● Incomplete Curing: Silicone rubber must form a stable cross-linked network during curing. If curing is insufficient, silicone oil will bleed more easily.

● Inadequate Volatile Removal: High-quality thermal conductive pads typically undergo high-temperature volatile removal (e.g., heating at 150–200°C for several hours) to reduce residual low-molecular-weight silicone oil.

(3) Environmental Factors

● High Temperatures: Thermal pads usually operate in environments ranging from 50°C to 150°C. If the temperature exceeds 200°C, oil bleeding will intensify.

● Long-Term Use: The longer the use period, the greater the likelihood of silicone oil migration, especially in continuously compressed environments.

2. Impact of Oil Bleeding on Circuits

To determine whether oil bleeding from thermal conductive pads can damage circuits, we need to analyze its potential effects from different perspectives.

2.1 Electrical Safety: Can It Cause Short Circuits?

● Silicone oil is an electrical insulator, with a volume resistivity typically between 10¹² and 10¹⁵ Ω·cm, higher than that of air and glass. Therefore, normally exuded silicone oil does not directly cause short circuits.

● However, if the silicone oil contains conductive impurities (such as metal particles or carbon powder), it may reduce insulation and affect circuit safety.

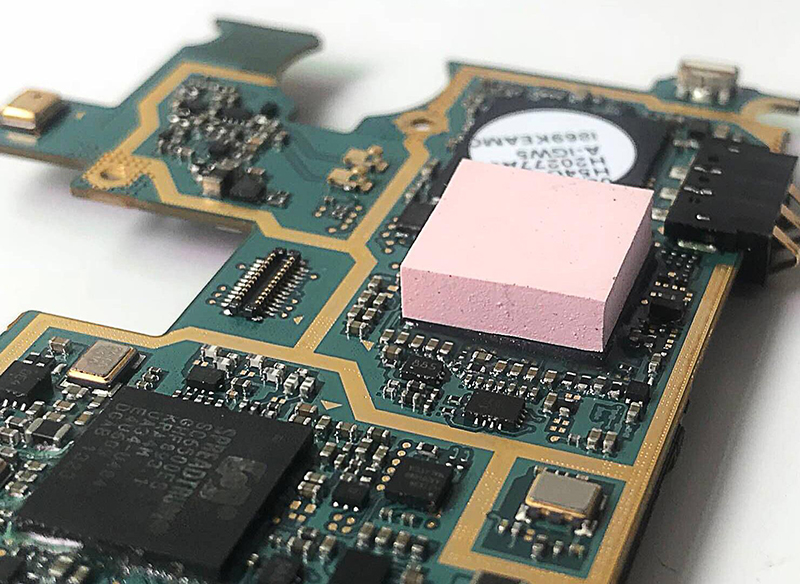

2.2 Decreased Thermal Performance

● The thermal conductivity of silicone oil is only about 0.1 W/m·K, much lower than that of thermal fillers (2–10 W/m·K).

● Excessive oil bleeding may reduce the overall thermal performance of the thermal pad, leading to higher component temperatures and potential reliability issues.

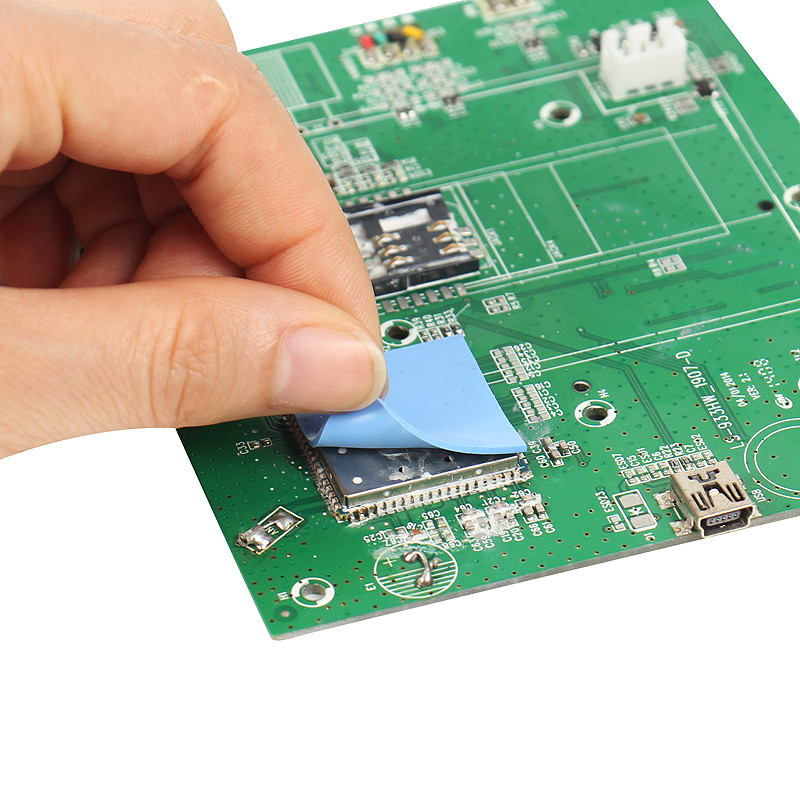

2.3 Circuit Board Contamination and Long-Term Reliability Risks

★ Silicone oil has low surface tension, making it prone to spreading and seeping onto PCB surfaces, especially in precision circuits and connectors.

★ Possible issues include:

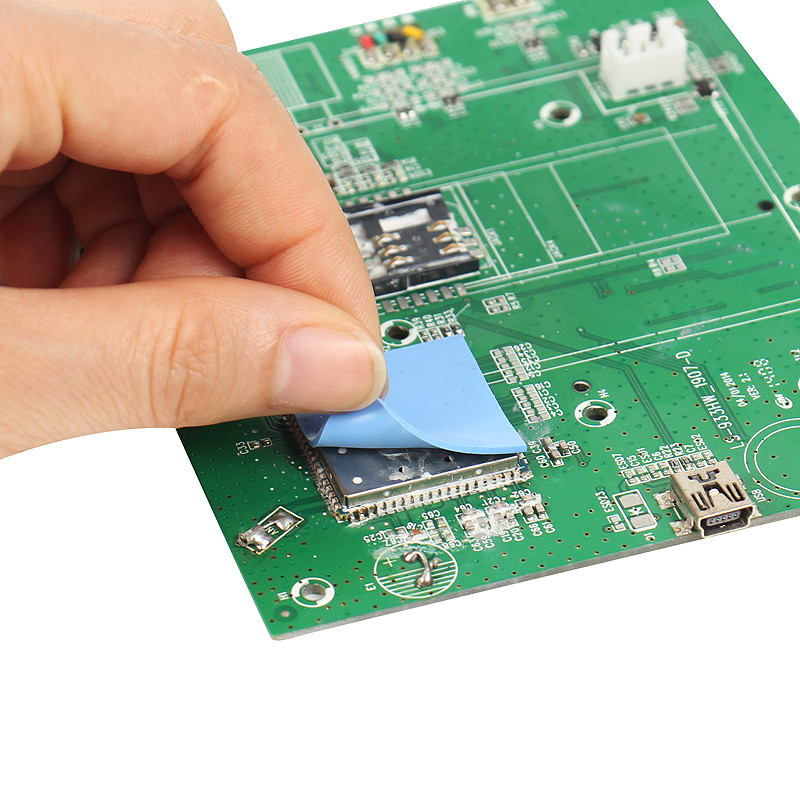

● Reduced contact reliability, leading to unstable signal transmission.

● Contaminated solder joints and connectors, affecting long-term durability.

● Accumulation of dust, accelerating equipment aging.

2.4 Impact on Plastic and Rubber Components

● Some plastics (such as PC and ABS) and rubbers (such as EPDM) are sensitive to silicone oil. Prolonged exposure may cause plastic embrittlement or rubber swelling/softening, reducing overall device reliability.

3. How to Choose Low-Bleeding Thermal Conductive Pads?

3.1 Selection Guidelines

1. Check Material Volatility Data

● Choose products with low volatility that meet ASTM E595 standards, focusing on Total Mass Loss (TML) and Collected Volatile Condensable Material (CVCM) indicators.

2. Select Products with High-Temperature Stability

● Thermal pads with ceramic fillers (e.g., boron nitride) are more temperature-resistant and have lower oil bleeding rates than those with standard aluminum oxide fillers.

3. Prioritize Products That Undergo High-Temperature Aging Tests

● For example, an 85°C/85% humidity 1000-hour aging test can verify long-term stability.

3.2 Maintenance & Optimization Tips

● Avoid extreme temperatures to slow silicone oil migration.

● Regularly clean circuit boards, especially connectors and terminals, to prevent silicone oil buildup.

● Consider alternative materials like thermal gels or ceramic-based thermal pads, which are less prone to oil bleeding.

3.3 NFION Thermal Solutions for Reliable Performance

NFION, a professional thermal material manufacturer, provides high-performance solutions with strict quality control to ensure minimal oil bleeding and long-term stability.

Why Choose NFION Thermal Pads?

✅ Low Oil Bleeding Technology: Advanced high-temperature volatile removal ensures long-term stability.

✅ Premium Raw Materials: High-purity silicone rubber and thermal fillers minimize low-molecular-weight silicone oil content.

✅ Reliability Testing: Products undergo 85°C/85% humidity 1000-hour aging tests to ensure safety.

✅ Wide Range of Thermal Conductivities: Options from 1 W/m·K to 12 W/m·K to meet various application needs.

Choosing NFION thermal conductive pads enhances heat dissipation efficiency while reducing the risk of oil bleeding, ensuring long-term stability for electronic components.

4. Conclusion

Oil bleeding in thermal conductive pads can indeed pose risks, particularly in high-precision and high-reliability electronic devices. Excessive oil exudation may affect heat dissipation, contaminate PCBs, reduce contact reliability, and even degrade certain plastic and rubber components. By selecting low-bleeding, high-quality materials, optimizing manufacturing processes (such as high-temperature volatile removal), and implementing proper circuit design (such as enhanced sealing and cleaning measures), engineers can effectively minimize these risks.

As electronic devices become increasingly sophisticated, addressing the oil bleeding issue in thermal conductive pads is crucial. Only through scientific material selection, stringent quality control, and efficient thermal management can circuit safety and stable operation be ensured, ultimately extending equipment lifespan.

CN >

CN >