With the continuous increase in data traffic and the performance of network devices, network switches, as the core equipment in data centers and enterprise networks, face increasingly serious heat management challenges. In high-load, high-frequency data exchange environments, the internal electronic components of network switches generate a large amount of heat. If this heat is not efficiently dissipated, it can negatively affect the device's stability, performance, and lifespan. Thermal gap pads, as an efficient thermal management material, play an indispensable role in the cooling system of network switches.

Overview of Thermal Gap Pads

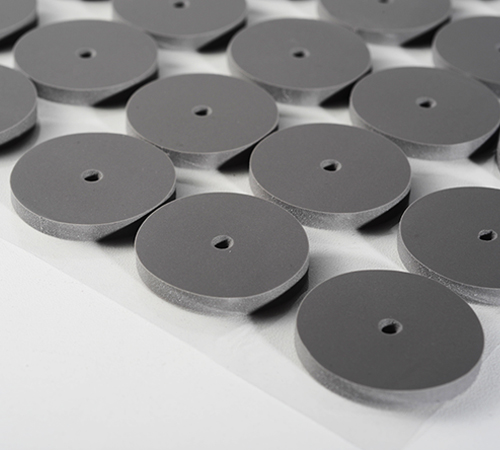

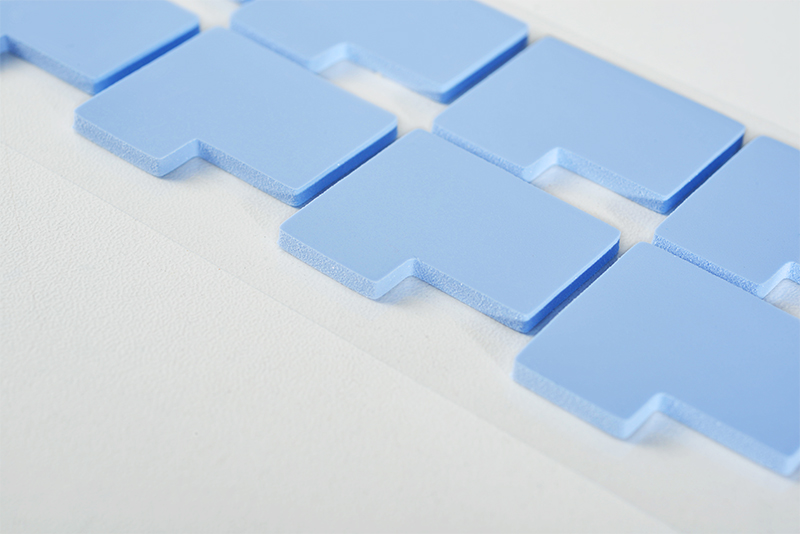

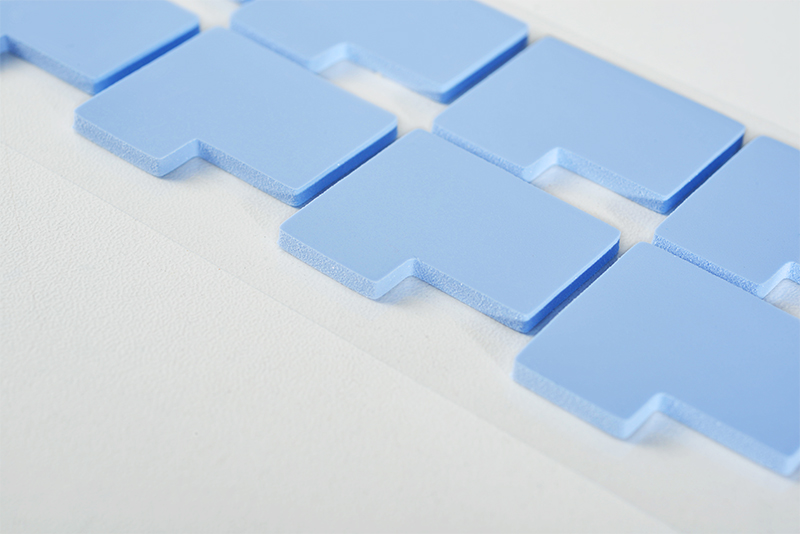

Thermal gap pads (Thermal Interface Material, TIM) are materials used for efficient heat transfer, usually made of silicone rubber mixed with fillers such as metal oxides or thermal conductive particles. They have relatively high thermal conductivity. Unlike traditional cooling methods (such as heatsinks and fans), thermal gap pads can directly contact heat sources and cooling elements, ensuring that heat is efficiently transferred to the cooling system, thereby lowering the temperature of the device.

The features of thermal gap pads include:

1. Excellent Thermal Conductivity: Effectively transfers heat generated by the device.

2. Good Flexibility: Adapts to various irregular surfaces and fills small gaps.

3. High Temperature Resistance: Retains its physical properties under high temperature conditions.

4. Electrical Insulation: Prevents electrical issues, ensuring the safety of the device.

In network switches, the role of thermal gap pads mainly manifests in the following areas:

1. Efficient Heat Transfer

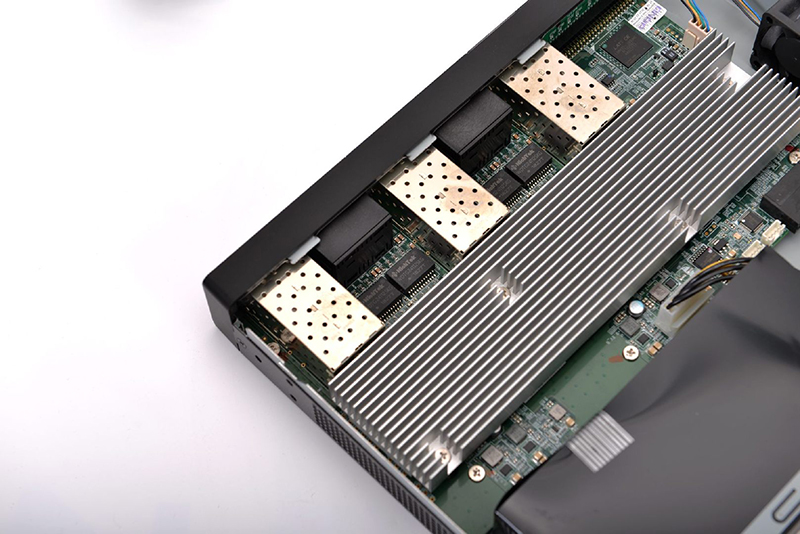

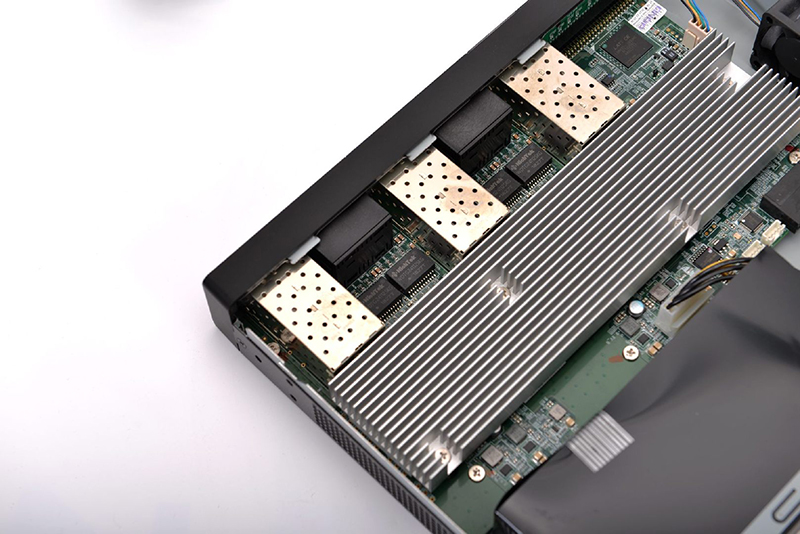

Key components in network switches, such as processors, memory modules, and power units, generate a lot of heat during operation. Thermal gap pads efficiently transfer this heat from the heat source to the heatsinks, heat spreaders, or other cooling systems. Due to their excellent thermal conductivity, thermal gap pads can quickly and evenly distribute the heat, preventing localized overheating and improving the cooling efficiency of the device.

2. Improvement of Thermal Contact

In the design of network switches, there are often small gaps between components such as the processor, heatsink, and base plate. Although these gaps are not easily noticeable, they can hinder heat transfer. The flexibility of thermal gap pads allows them to fill these small gaps, creating a tighter thermal contact and improving heat transfer efficiency. This property makes thermal gap pads an ideal material for solving the problem of uneven cooling in devices.

3. Reduction of Thermal Stress

Since the electronic components in network switches are subjected to temperature fluctuations over extended periods, thermal stress can cause component damage or solder joint failure. Thermal gap pads not only enhance heat transfer but also help alleviate thermal stress. Their elasticity and flexibility enable thermal gap pads to adapt to thermal expansion and contraction of the components, effectively protecting internal components and extending the device's lifespan.

4. Enhancing System Stability

Efficient cooling ensures that network switches maintain stable performance during long-term, high-load operation. By optimizing thermal management, thermal gap pads reduce temperature fluctuations within the switch, thus enhancing device stability. Stable operating temperatures not only improve the reliability of network switches but also reduce the risk of failure and downtime.

5. Simplification of Cooling Design

In the thermal management design of network switches, thermal gap pads offer engineers a simple yet highly effective solution. Compared to traditional cooling systems like heatsinks or liquid cooling, using thermal gap pads can simplify design complexity, reduce costs, and provide outstanding cooling performance. Due to their flexibility and adaptability, thermal gap pads can be used with various components of different shapes and sizes, making them highly versatile.

Selection and Application of Thermal Gap Pads

Selecting the appropriate thermal gap pad is key to ensuring optimal cooling performance in network switches. Here are some factors to consider when choosing thermal gap pads:

1. Thermal Conductivity

Thermal conductivity is one of the core performance indicators of thermal gap pads. Choosing a pad with appropriate thermal conductivity can significantly improve cooling efficiency. For high-performance network switches, it is recommended to select thermal gap pads with higher thermal conductivity to handle heavier thermal loads.

2. Thickness and Compressibility

The thickness and compressibility of thermal gap pads directly affect the quality of contact between the pads and component surfaces. Thin and highly compressible materials can fill smaller gaps, improving thermal contact. Selecting the right thickness and compressibility maximizes cooling effectiveness.

3. Environmental Adaptability

The high-temperature resistance and environmental adaptability of thermal gap pads are critical, especially in high-temperature operating environments. The stability and durability of the material determine whether it can maintain its thermal conductivity over time.

4. Electrical Insulation

In addition to good thermal conductivity, thermal gap pads must also provide electrical insulation to prevent short circuits and electrical issues. Therefore, it is essential to ensure that the selected pads meet the electrical insulation requirements.

Conclusion

The role of thermal gap pads in network switches cannot be overlooked. By providing efficient heat transfer, improving thermal contact, alleviating thermal stress, and enhancing system stability, thermal gap pads optimize the cooling performance of devices and extend their lifespan. As the performance of network switches continues to increase, the demand for effective thermal management solutions also rises. Thermal gap pads, as an efficient thermal management material, will play an increasingly important role in the design of future network switches.

CN >

CN >