When it comes to effective thermal management in electronic devices, choosing the right thermal interface material (TIM) is crucial. Two common options are thermal paste (also known as thermal grease) and thermal pads. While both serve the same general purpose—facilitating heat transfer between components like CPUs, GPUs, or other heat-generating parts and heat sinks—they are distinct materials with different properties. A common question that arises among engineers, technicians, and DIY enthusiasts is whether thermal paste should be applied on top of thermal pads to improve performance. NFION delves into the factors that influence this decision, providing a comprehensive analysis of when and why you might or might not apply thermal paste to thermal pads.

Understanding Thermal Pads and Thermal Paste

Before addressing the question directly, it’s important to understand the role and characteristics of both thermal pads and thermal paste.

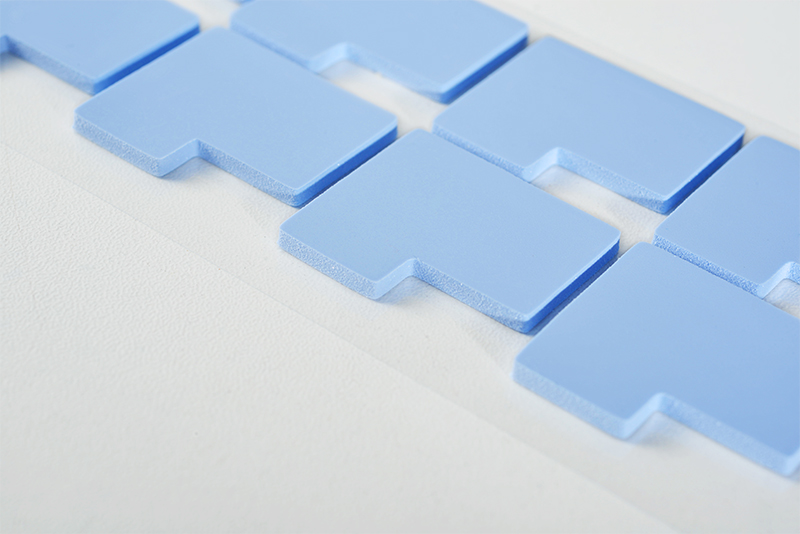

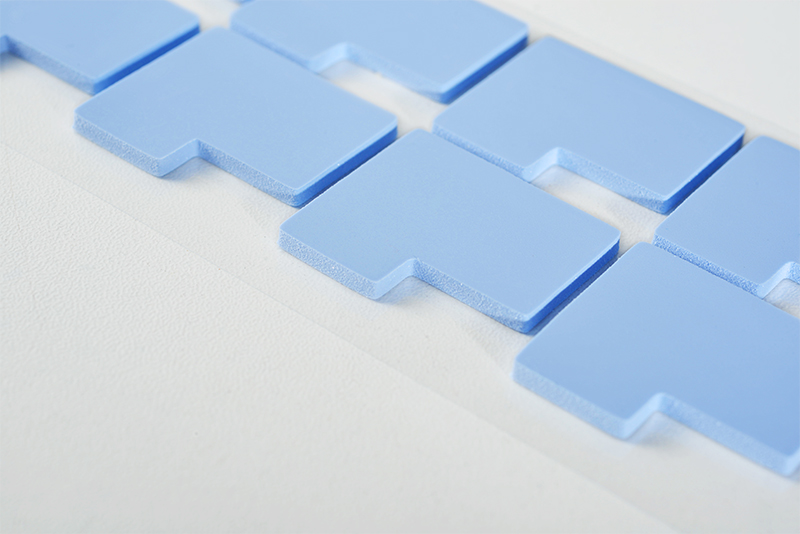

Thermal Pads:

Thermal pads are pre-formed materials made from thermally conductive compounds, often infused with a combination of silicone, ceramics, and fillers. They are typically used in applications where ease of use, consistency, and reliability are prioritized. Thermal pads come in various thicknesses and are designed to be placed directly between heat-generating components and heat sinks. Their key advantage lies in their simplicity and uniformity, eliminating the need for messy application and the risk of over- or under-applying.

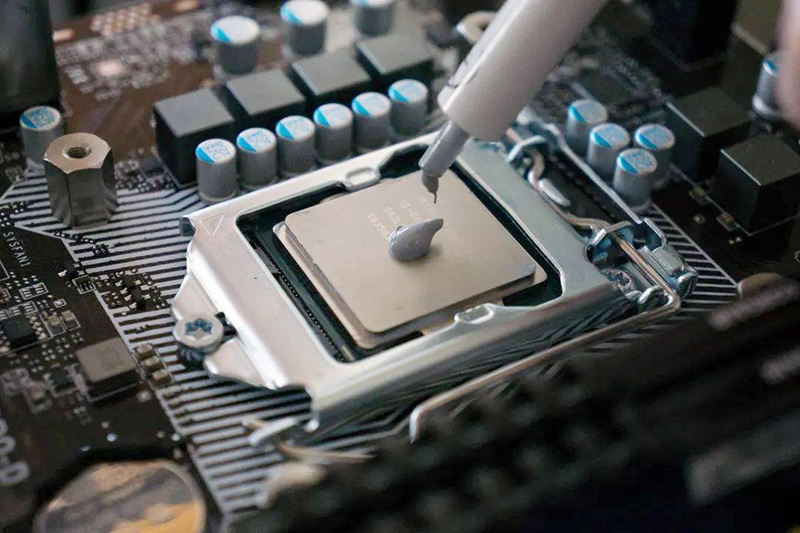

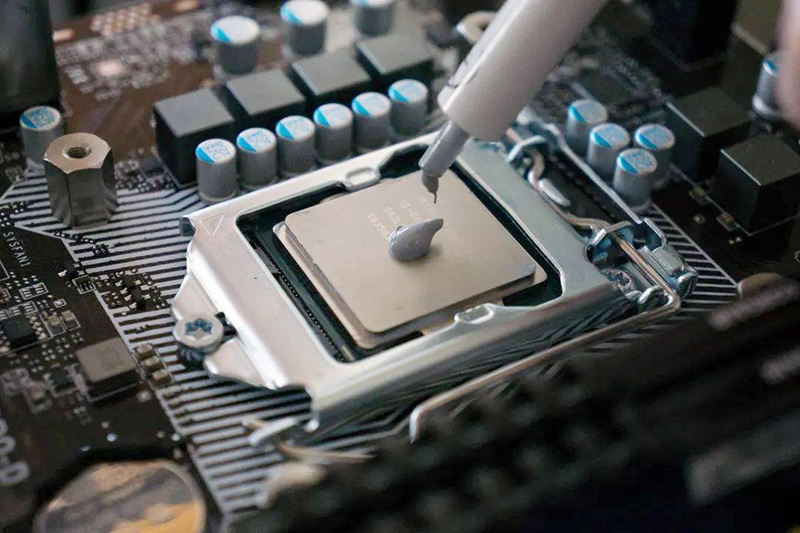

Thermal Paste:

Thermal paste, or thermal grease, is a viscous substance that is applied in small amounts between two surfaces to improve heat transfer. It is primarily made of a combination of thermally conductive materials suspended in a binder, such as metal oxides, ceramics, or carbon. Thermal paste fills microscopic gaps between surfaces that might be present even with the best mechanical contact, ensuring maximum heat transfer.

Thermal Performance: Pad vs. Paste

The fundamental purpose of both thermal pads and thermal paste is to reduce thermal resistance between two surfaces, typically a processor and its heat sink. However, they do so in different ways.

Thermal Pads:

Thermal pads offer moderate thermal conductivity and are generally thicker than thermal paste. Their efficiency is influenced by factors such as thickness, material composition, and pressure exerted during installation. While thermal pads are convenient, they typically provide less heat transfer performance compared to high-quality thermal paste. This is because thermal pads can’t achieve the same level of microscopic contact as thermal paste, especially on surfaces that are not perfectly flat.

Thermal Paste:

Thermal paste excels in filling micro-gaps and irregularities between the surfaces. It offers superior thermal conductivity when applied properly, as it can create a much thinner layer, improving thermal transfer. High-performance thermal pastes can achieve excellent heat dissipation properties, often outperforming thermal pads in terms of pure thermal performance.

Should Thermal Paste Be Applied to Thermal Pads?

In general, applying thermal paste on top of thermal pads is not necessary and, in most cases, not recommended. Here’s why:

1. Redundant Layering:

Thermal pads, by their very nature, are designed to be a complete solution for thermal interface needs. Adding thermal paste on top of a thermal pad does not significantly improve heat transfer. In fact, it may reduce the overall performance due to the combination of two materials with different thermal properties and viscosities, leading to less efficient heat conduction.

2. Increased Thickness:

Thermal pads already add a certain amount of thickness between the heat-generating component and the heat sink. Applying thermal paste on top will further increase the thickness of the thermal interface, which can create additional thermal resistance, potentially reducing performance.

3. Practical Considerations:

Thermal paste can create a mess if improperly applied, and combining it with a thermal pad could complicate the installation process. The paste may spill over, leading to unwanted contamination or uneven distribution, which could compromise the overall thermal management.

When Could Thermal Paste Be Useful with Thermal Pads?

There are rare situations where combining thermal paste with thermal pads might be considered:

1. Low-Quality Thermal Pads:

If the thermal pads being used are of low quality, particularly those with poor thermal conductivity or inconsistent thickness, adding a thin layer of thermal paste on top might marginally improve heat transfer. However, this is typically a workaround rather than a solution, as the primary issue lies with the pad itself.

2. High-Pressure Applications:

In high-pressure scenarios, such as those involving very tight heatsink mounting, the compression of the thermal pad might result in uneven contact. In these cases, applying a thin layer of thermal paste on top of the thermal pad could help fill gaps and improve contact surface uniformity.

3. Critical High-Performance Builds:

In highly critical, high-performance applications—such as gaming PCs or overclocking setups—where every degree of temperature reduction matters, some users might choose to apply thermal paste on top of a thermal pad to squeeze out additional performance. However, in these situations, high-quality thermal paste or thermal pads specifically designed for high-performance scenarios would likely yield better results.

Alternatives to Using Both Thermal Pads and Paste

If your goal is optimal heat transfer, it may be best to use one of the two solutions, not both. Here’s an overview of potential alternatives:

Using Only Thermal Paste:

For high-end thermal performance, using only a high-quality thermal paste is often the best option, especially for CPU and GPU applications. It offers the most efficient thermal transfer by creating the thinnest and most uniform layer between components.

Using Only Thermal Pads:

In applications where ease of use, consistency, and long-term reliability are important—such as in devices with less stringent thermal demands—thermal pads are often sufficient. For mass production environments or consumer devices, pads provide an efficient, low-maintenance solution.

Conclusion

In summary, while the idea of applying thermal paste on top of thermal pads might seem like a way to enhance thermal performance, it is generally not a necessary or beneficial practice. The inherent design of thermal pads already meets the needs of most applications, and adding thermal paste typically offers no significant advantages and can even hinder performance.

For applications that demand the highest thermal performance, it is recommended to choose either high-quality thermal paste or thermal pads, depending on the specific requirements of your project. When in doubt, selecting the right material based on your application’s thermal needs, installation considerations, and component types will provide the best results.

CN >

CN >