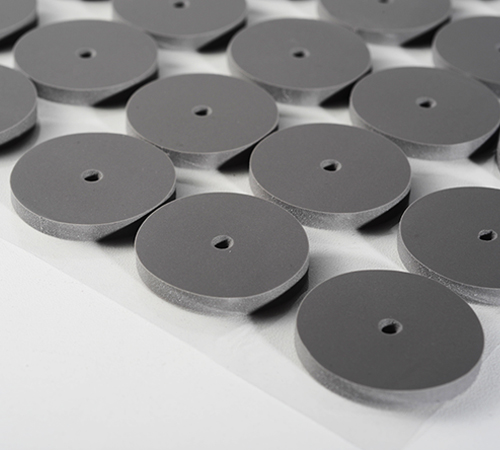

Silicone thermal pads, widely used in electronic devices as essential thermal management materials, not only offer excellent thermal conductivity but also need to provide effective electrical insulation in complex electrical environments. Breakdown voltage, a key indicator of the electrical insulation performance of silicone thermal pads, directly impacts their safety and reliability in practical applications. To meet the stringent requirements for high electrical insulation and stability in electronic devices, enhancing the breakdown voltage of silicone thermal pads is a crucial aspect of product design and manufacturing. Nfion explores effective methods to improve the breakdown voltage of silicone thermal pads from multiple perspectives, including material composition, thickness, environmental conditions, production processes, and surface treatments.

Material Formulation Optimization

The main components of silicone thermal pads include a silicone rubber matrix and thermally conductive fillers, which determine the material's thermal conductivity and electrical insulation properties. By selecting and adjusting material formulations, it is possible to effectively improve the breakdown voltage:

1. Selection of High-Insulation Thermal Fillers: Thermal fillers such as boron nitride and aluminum oxide enhance thermal conductivity and affect the material's electrical performance. High-insulation fillers like boron nitride exhibit excellent insulating properties, balancing thermal and insulation performance. Optimizing the proportion and distribution of fillers can effectively improve both thermal conductivity and breakdown voltage.

2. High-Purity Silicone Rubber Matrix: The purity of silicone rubber as the base material significantly affects electrical insulation. Using high-purity silicone rubber helps reduce impurities' impact, improving the material's breakdown voltage.

3. Careful Use of Additives: Additives like plasticizers or flame retardants are often used to enhance flexibility and heat resistance. However, excessive additives may compromise electrical performance, so selecting appropriate types and amounts is essential to ensure they do not reduce breakdown voltage.

Thickness Control

The thickness of silicone thermal pads directly influences their electrical insulation performance. Generally, breakdown voltage is proportional to thickness; that is, thicker materials offer higher breakdown voltage. This is because thicker materials provide a longer pathway for electrical current, making electrical breakdown less likely. However, increasing thickness may reduce thermal efficiency and flexibility, so finding a balance between breakdown voltage and thermal performance is essential in designing silicone thermal pads.

Influence of Environmental Conditions

The breakdown voltage performance of silicone thermal pads may vary under different environmental conditions, especially with changes in temperature and humidity:

1. Temperature: The breakdown voltage of silicone thermal pads decreases as temperature rises. High temperatures may reduce the material's insulation properties. Therefore, in high-temperature environments, selecting heat-resistant materials or enhancing high-temperature performance through proper modification is key to maintaining high breakdown voltage.

2. Humidity: In humid environments, moisture can infiltrate the material, decreasing insulation and lowering breakdown voltage. For applications in humid environments, moisture-resistant materials or protective treatments should be considered.

3. Voltage Fluctuations: In practical applications, electronic devices are often subject to voltage fluctuations or surges, which can cause instant breakdown. To counter this, selecting silicone thermal pads with a higher breakdown voltage ensures the material maintains sufficient safety in fluctuating voltage environments.

Production Process Improvement

Production process control has a significant impact on the breakdown voltage of silicone thermal pads. A refined production process can improve the internal structural stability of the material, enhancing electrical insulation performance:

1. Uniform Dispersion of Fillers: The distribution of thermal fillers in the silicone matrix directly impacts breakdown voltage. Uneven filler distribution can lead to localized conductive pathways, reducing breakdown voltage. Adopting efficient dispersion technology ensures even filler distribution, improving electrical performance.

2. Optimized Vulcanization Process: An optimized vulcanization process ensures structural stability. Control over vulcanization temperature and time is critical for the electrical performance of silicone thermal pads, enhancing both mechanical strength and breakdown voltage.

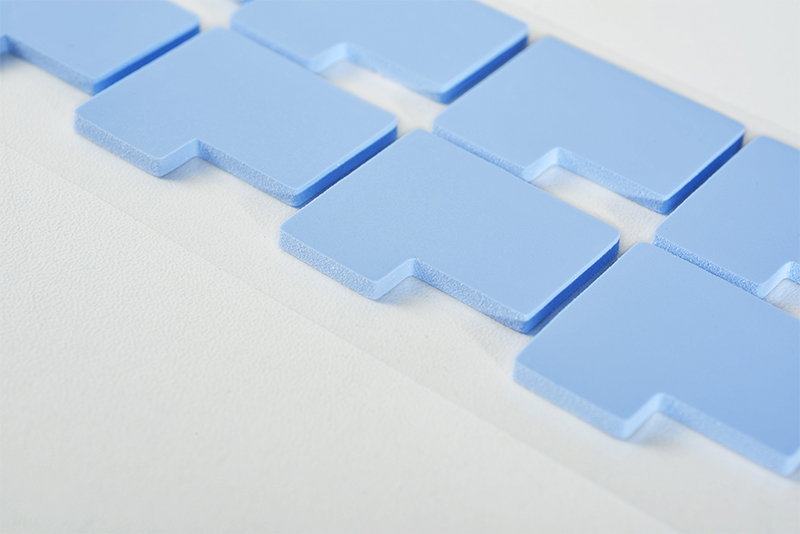

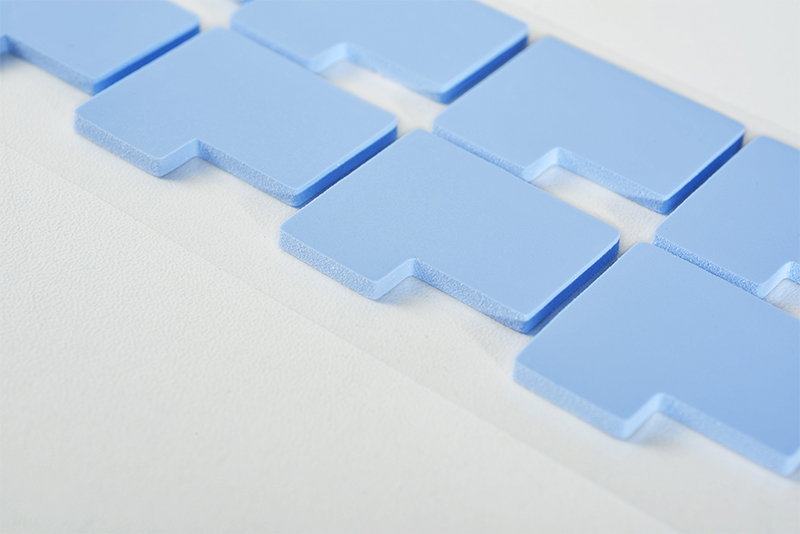

Surface Treatments and Composite Structures

Surface treatments and composite structures also offer effective solutions to improve breakdown voltage:

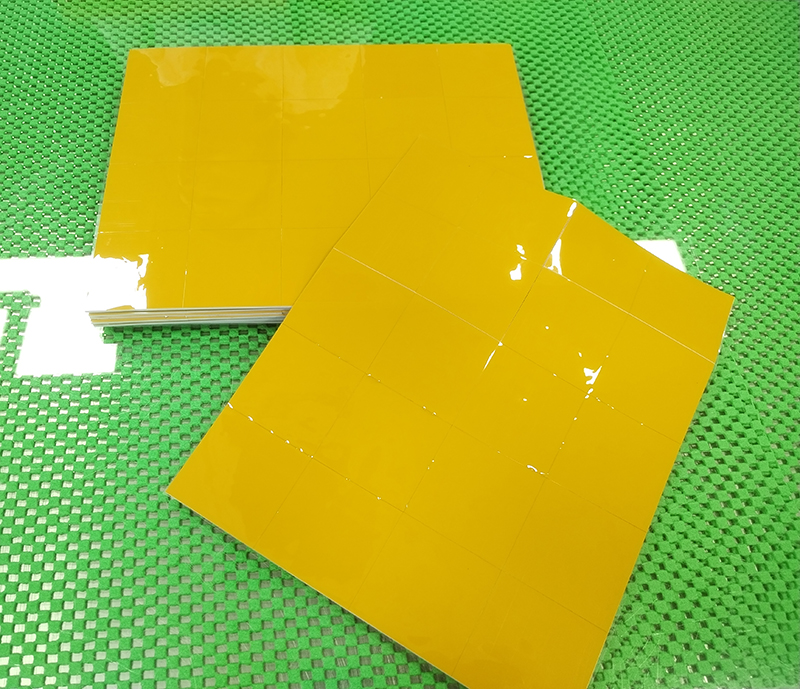

1. Surface Coating or Plating: Coating or plating the surface of silicone thermal pads enhances water resistance and resistance to electrical breakdown. Such surface treatments also improve moisture and oxidation resistance, extending the material's lifespan.

2. Composite Thermal Insulation Sheets: Adding a layer of thermal insulation sheet to the silicone thermal pad can further increase breakdown voltage. Thermal insulation sheets are usually made of materials with superior insulation properties, enhancing electrical insulation without compromising thermal conductivity.

3. Polyimide (PI) Film Technology: Polyimide (PI) film, widely used in high-temperature and high-voltage applications, is a highly insulating material. Laminating PI film onto the surface of silicone thermal pads significantly increases breakdown voltage, enabling the material to maintain excellent insulation in extreme electrical environments. PI film not only has high temperature resistance but also excellent mechanical strength and aging resistance, making it particularly suitable for high-temperature or humid conditions.

Conclusion

As a key parameter ensuring the electrical safety of electronic devices, the breakdown voltage of silicone thermal pads is influenced by various factors, including material formulation, thickness, environmental conditions, production processes, and surface treatments. In enhancing the breakdown voltage of silicone thermal pads, it is crucial to strike a balance between thermal and electrical performance by optimizing material composition, improving production processes, and incorporating composite structures to meet the demands of high-voltage, high-temperature, and high-humidity applications. In the future, with the continuous emergence of new materials and processes, the electrical insulation performance of silicone thermal pads will be further improved, providing more reliable protection for the safe and stable operation of electronic devices.

CN >

CN >