Efficient Heat Dissipation: Nfion Thermal Silicone Pads Safeguard AC-DC Power Modules

As modern electronic devices continue to upgrade and become more complex, AC-DC power modules, as the core components of energy conversion, face increasingly severe heat dissipation challenges. Increased power density, smaller sizes, and higher operating frequencies result in more heat being generated during operation. If this heat cannot be dissipated efficiently, it will lead to system performance degradation or even failure. Nfion Electronics provides thermal silicone pads with excellent thermal conductivity and reliable insulation properties, offering a perfect solution for the heat dissipation issues in AC-DC power modules.

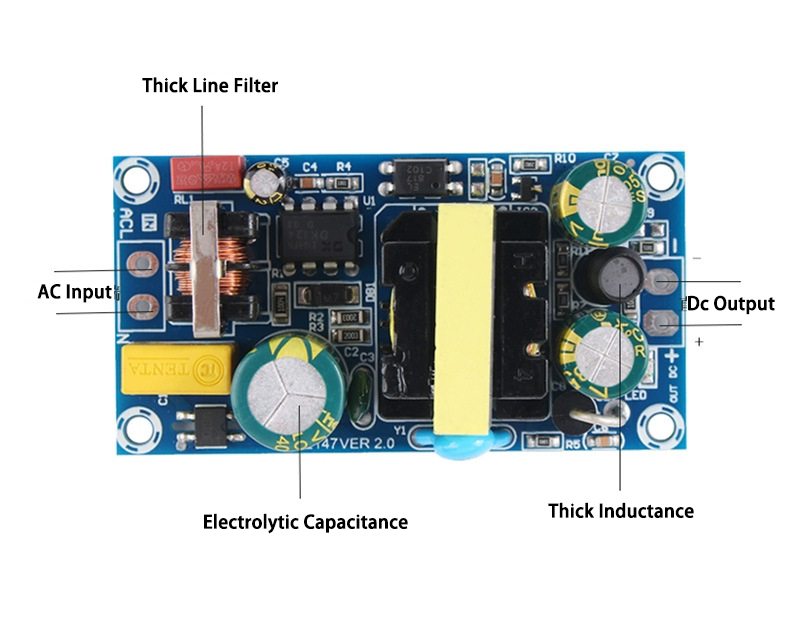

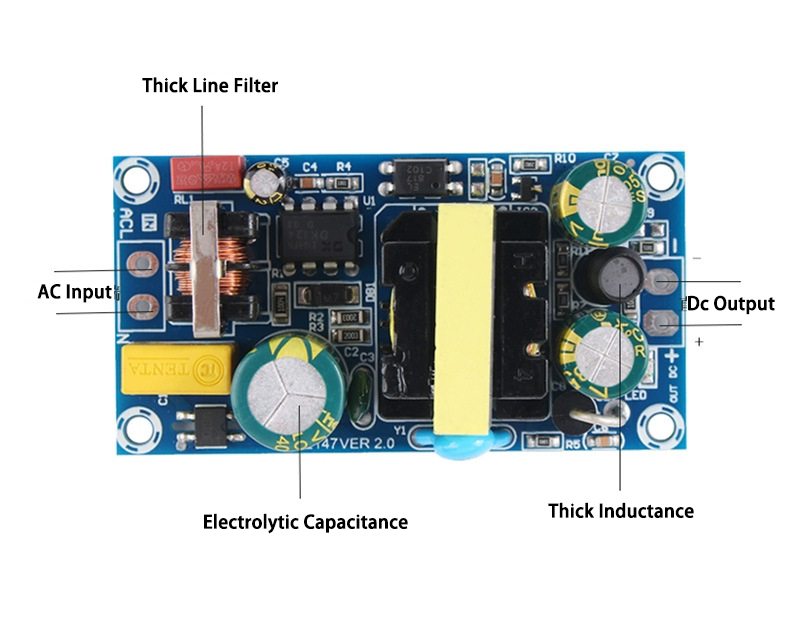

Core Issues of Heat Dissipation in AC-DC Power Modules

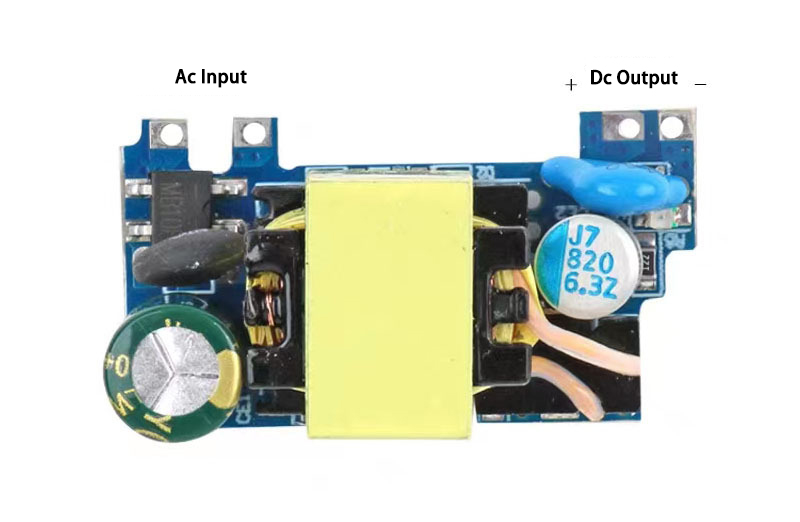

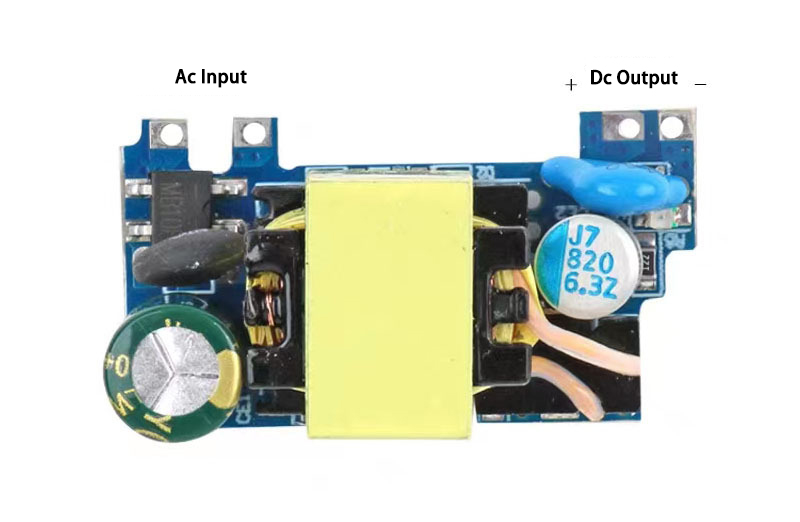

AC-DC power modules convert alternating current (AC) to direct current (DC), supplying stable power. During this conversion process, components like MOSFETs, rectifiers, and transformers generate heat due to internal currents and frequent switching actions. If this heat is not effectively dissipated, it will not only increase the component’s temperature, affecting performance but also accelerate aging and even cause thermal damage to the module.

Thus, efficient heat dissipation from the heat source is a key consideration in AC-DC power module design.

The Dangers of Heat Accumulation

The accumulation of heat in a power module can lead to the following problems:

1. Decreased component performance: High temperatures negatively impact the conductivity and switching speed of semiconductor components, reducing the overall module efficiency.

2. Accelerated component aging: Rising temperatures accelerate chemical reactions in electronic components, shortening their lifespan. Poor temperature control can significantly affect the reliability of long-running devices.

3. Increased risk of thermal failure: If the module’s temperature exceeds the tolerance limits of the components, thermal failure could occur, leading to shorts or even burning of the device.

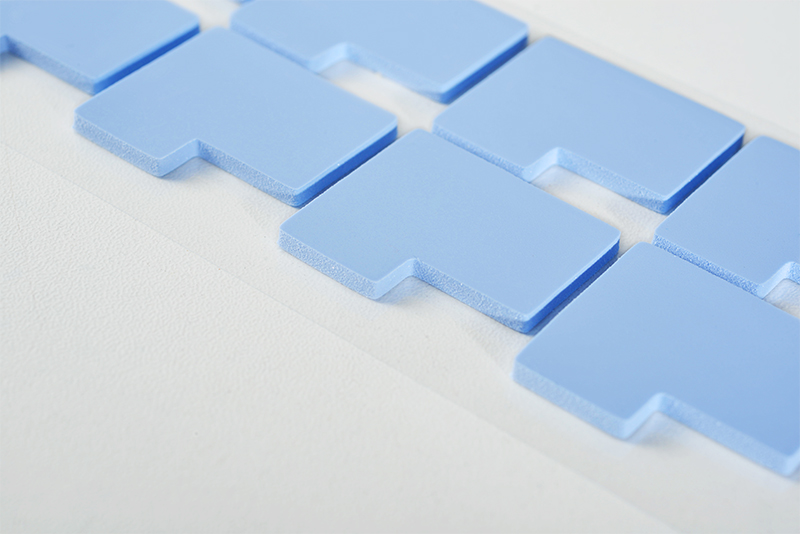

The Advantages of Nfion's Thermal Silicone Pads

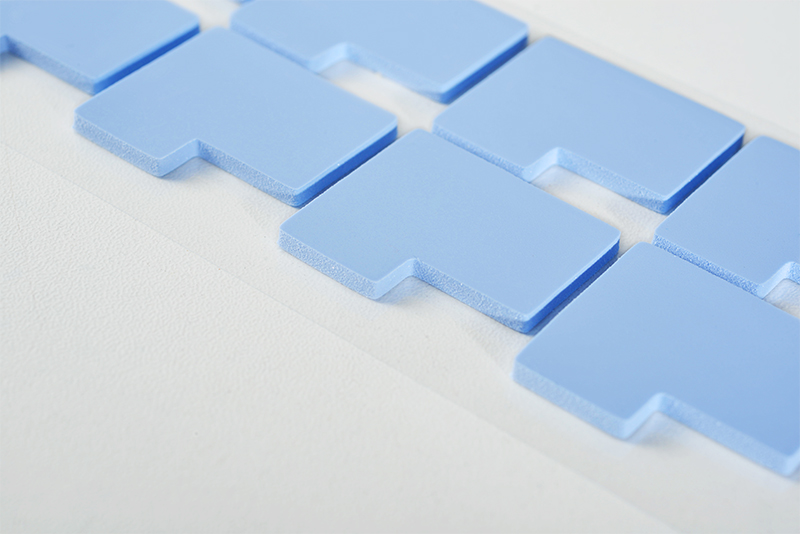

Nfion's thermal silicone pads are specifically designed to solve heat dissipation problems in electronic devices, especially for AC-DC power modules facing high power density and high-temperature conditions. Their main features include:

1. Excellent Thermal Conductivity

Nfion’s thermal silicone pads use high thermal conductivity fillers and flexible silicone base materials with a thermal conductivity of up to 3.0 W/m·K or higher, rapidly transferring heat from the heat-generating components to heat sinks or metal housings. Compared to traditional materials, thermal silicone pads provide more efficient heat transfer, significantly reducing the surface temperature of components.

2. Outstanding Electrical Insulation

In addition to thermal conductivity, the heat dissipation design of AC-DC power modules must ensure electrical insulation. Nfion’s thermal silicone pads offer excellent insulation with breakdown voltages exceeding 10kV, ensuring efficient heat dissipation while preventing electrical interference and short circuits between components, ensuring system safety.

3. Superior Flexibility and Compressibility

In the installation of AC-DC power modules, irregular gaps often exist between components. Traditional hard thermal materials cannot fully cover contact surfaces, leading to reduced thermal efficiency. Nfion’s thermal silicone pads possess excellent softness and compressibility, filling irregular gaps tightly, reducing thermal resistance, and enhancing heat transfer. Their flexibility also buffers mechanical stress, protecting components from damage.

4. Stable Long-Term Performance

Nfion's thermal silicone pads exhibit excellent high-temperature resistance and aging resistance, maintaining their thermal conductivity and insulation properties over the long term, even under continuous high-temperature or harsh conditions. This ensures the reliable long-term operation of AC-DC power modules.

Application of Nfion’s Thermal Silicone Pads in AC-DC Power Modules

Nfion’s thermal silicone pads are widely applied in various AC-DC power modules, especially in high-density and miniaturized power designs. In these modules, space is limited, and heat generation is concentrated, making efficient thermal materials essential. The thermal silicone pads can be flexibly applied in the following areas:

1. Between power components and heat sinks: Transferring heat from power components to heat sinks or enclosures.

2. Between PCBs and metal baseplates: Transferring heat from the PCB to the metal housing or other heat-dissipating parts, ensuring uniform temperature distribution.

3. In areas with concentrated heat sources: Such as transformers and rectifiers, where heat generation is concentrated, preventing local overheating through efficient heat transfer.

Conclusion

As electronic devices continue to evolve, the heat dissipation challenges faced by AC-DC power modules are becoming more acute. Nfion’s thermal silicone pads offer an excellent solution, providing superior thermal conductivity, electrical insulation, and flexibility, addressing heat management issues in modules and ensuring stable, efficient operation. By applying Nfion’s thermal silicone pads, the reliability and lifespan of AC-DC power modules are significantly enhanced, offering competitive technical support to the industry.

CN >

CN >