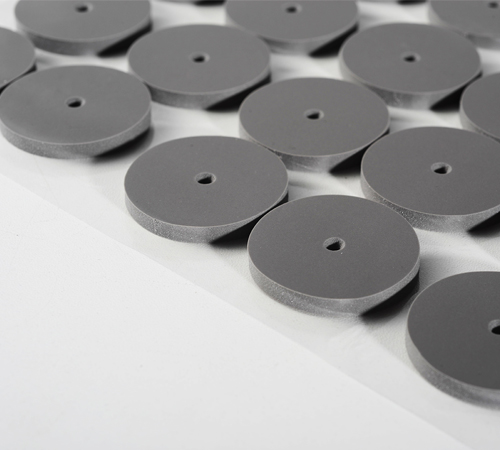

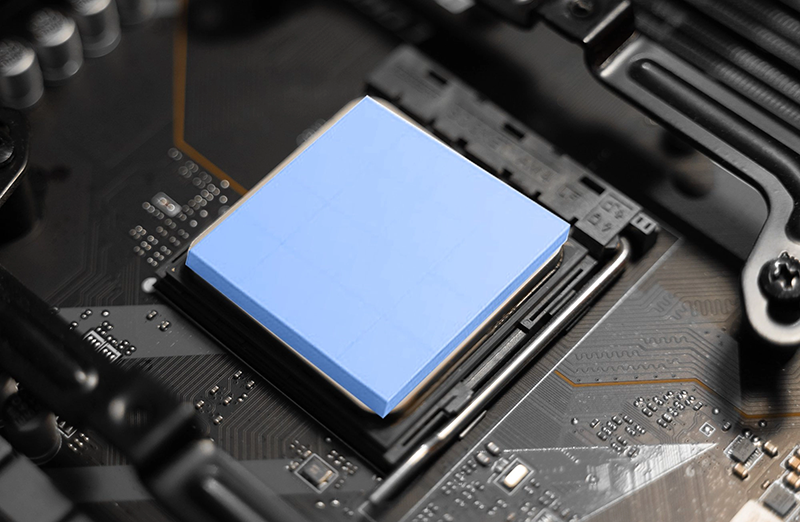

Thermal silicone pads, as an efficient thermal interface material, are widely used in electronic devices, LED lighting, and power modules that require high levels of heat dissipation. Their primary function is to effectively transfer heat generated by electronic devices to a heat sink or external environment, ensuring stable operation. However, during thermal conduction, thermal silicone pads may generate certain mechanical stress, especially under high-temperature or thermal cycling conditions. Does this stress affect electronic devices?

Working Mechanism of Thermal Silicone Pads

Sources of Stress and Influencing Factors

1. Installation Pressure: Applying adequate pressure during installation ensures proper contact between the pad and the device. However, excessive pressure may lead to deformation or damage to sensitive components (e.g., chips, ceramic capacitors).

2. Thermal Expansion and Contraction: Electronic devices experience temperature changes during operation. Since different materials have varying coefficients of thermal expansion, stress may occur between the silicone pad and the device. During high temperatures, the pad expands, exerting pressure on the device; as temperatures drop, the material contracts, generating reverse stress. Repeated thermal cycling may accelerate device aging.

3. Material Aging: Over time, the flexibility and elasticity of thermal silicone pads may diminish, reducing their ability to buffer stress and increasing mechanical stress on the device surface.

Impact of Stress on Devices

1. Structural Damage: Stress may cause mechanical damage to fragile electronic components, such as cracks in solder joints or substrate fractures. Such damage is often irreversible, potentially leading to device failure.

2. Reduced Thermal Conductivity: Poor contact or material performance changes due to stress may reduce heat conduction efficiency, increasing the device's operating temperature and affecting its stability.

How to Minimize Stress Impact

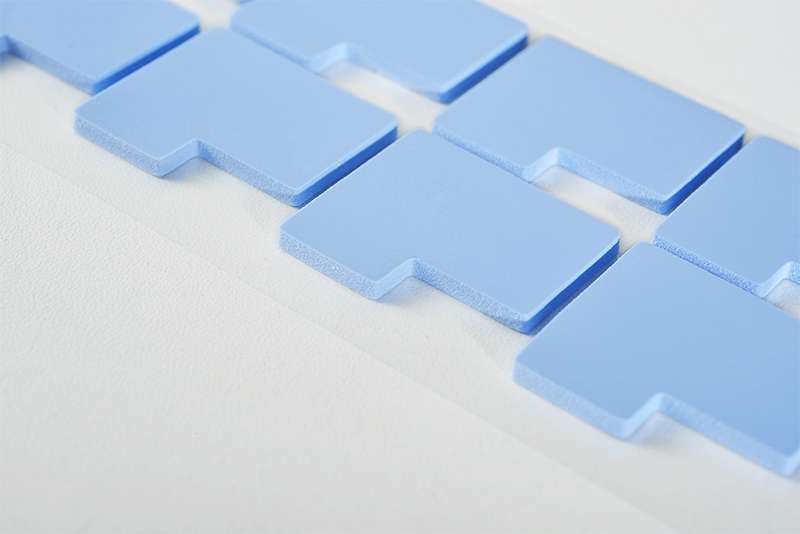

1. Selecting Appropriate Materials: Choose materials with suitable flexibility and compressibility according to the specific application to balance heat transfer efficiency and mechanical stress.

2. Optimizing Installation Methods: Control installation pressure to ensure proper contact without exerting excessive mechanical stress on the device. Avoid over-tightening or frequent adjustments to prevent cumulative stress.

3. Temperature Management: In high-temperature or thermal cycling environments, use thermally stable materials and design efficient heat dissipation systems to reduce temperature variations and stress generation.

4. Regular Inspection and Replacement: Periodically inspect the condition of thermal silicone pads in long-term, high-intensity environments and replace aging or deteriorating materials promptly to ensure proper device operation.

Conclusion

The stress generated by thermal silicone pads during heat transfer can indeed affect electronic devices, especially under improper installation or prolonged use. However, by selecting suitable thermal silicone pads and optimizing installation and heat dissipation design, the negative impact of such stress can be effectively minimized.

In conclusion, thermal silicone pads are a reliable thermal interface material, and as long as stress issues are considered and addressed during application, their impact on devices can be controlled within safe limits.

CN >

CN >