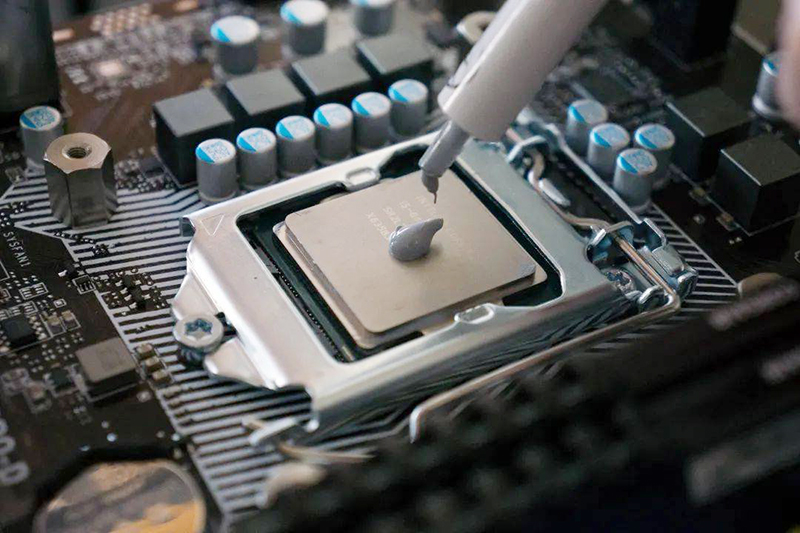

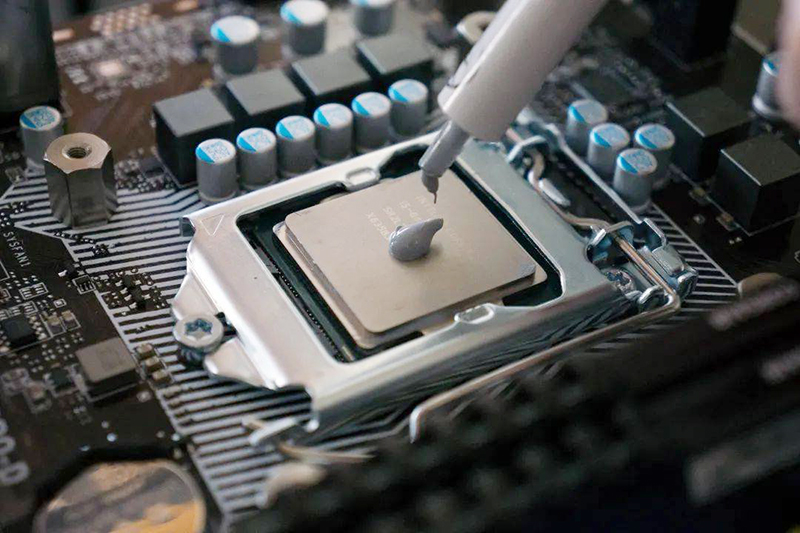

Thermal grease is widely used in the cooling systems of electronic devices and computer hardware. Its main function is to fill the microscopic gaps between heat-generating components and heat sinks, thereby improving thermal conductivity. However, during prolonged use, thermal grease may exhibit sedimentation and clumping, which not only affects its thermal performance but can also negatively impact the normal operation of the equipment. This article delves into the causes of thermal grease sedimentation and clumping and provides related preventive measures.

Composition and Characteristics of Thermal Grease

Thermal grease is primarily composed of base oil (such as silicone oil), thermal fillers (such as aluminum oxide, zinc oxide), and a small amount of additives. These components work together to provide good thermal conductivity and suitable viscosity. However, the physical and chemical properties of these different components vary greatly, which can lead to separation and sedimentation during long-term use.

Main Causes of Thermal Grease Sedimentation and Clumping

1. Compatibility Issues Between Base Oil and Fillers

The base oil and thermal fillers in thermal grease are not fully compatible when mixed, especially under high temperature or high load conditions. The different molecular movement rates of the base oil and fillers can cause separation. The base oil may seep out while the heavier fillers settle, eventually leading to clumping.

2. Temperature Cycling Effects

Electronic devices experience constant temperature changes during operation, especially high-performance computing devices, which undergo significant temperature fluctuations. Repeated temperature changes can cause thermal grease to expand and contract, exacerbating the separation between the base oil and fillers, leading to sedimentation and clumping.

3. Aging After Prolonged Use

Thermal grease can age during prolonged use, with the base oil potentially evaporating or undergoing chemical degradation, resulting in decreased viscosity and flowability. Over time, filler particles gradually lose their base oil coating and coagulate into clumps, affecting thermal performance.

4. External Environmental Factors

External environmental factors such as humidity and dust can also impact the stability of thermal grease. High humidity environments can cause thermal grease to absorb moisture, affecting its viscosity and flowability; dust particles entering the thermal grease can lead to redistribution and sedimentation of the fillers.

Preventive Measures

1. Selecting High-Quality Thermal Grease

Choosing high-quality thermal grease, particularly products with good compatibility between the base oil and fillers, can significantly reduce the risk of sedimentation and clumping. High-quality thermal grease typically undergoes strict quality control during production, resulting in better stability and durability.

2. Optimizing Equipment Cooling Design

Optimizing the cooling design of electronic devices to reduce temperature fluctuations and high-temperature areas can effectively extend the life of thermal grease. Properly designing the placement of heat sinks and fans to ensure rapid and efficient heat dissipation is key to preventing thermal grease aging.

3. Regular Maintenance and Replacement

For electronic devices running for extended periods, regularly checking the state of the thermal grease and promptly replacing it if clumping or performance degradation is observed is essential. Regular maintenance can ensure effective heat dissipation and prevent overheating issues caused by aging thermal grease.

4. Controlling the Usage Environment

Keeping the usage environment of electronic devices dry and clean, avoiding high humidity and dust intrusion, helps prolong the life of thermal grease. In industrial environments, it is advisable to take appropriate protective measures to minimize the impact of external factors on thermal grease.

Conclusion

The sedimentation and clumping of thermal grease result from a combination of factors, ranging from material properties to usage environment. By selecting high-quality thermal grease, optimizing cooling design, performing regular maintenance, and controlling the usage environment, sedimentation and clumping can be effectively prevented, ensuring the normal operation and longevity of electronic devices. Understanding and addressing these factors is crucial for improving the efficiency and reliability of heat dissipation in electronic equipment.

CN >

CN >