Why Use Thermal Silicone Pads Instead of Thermal Grease in LED Heat Dissipation?

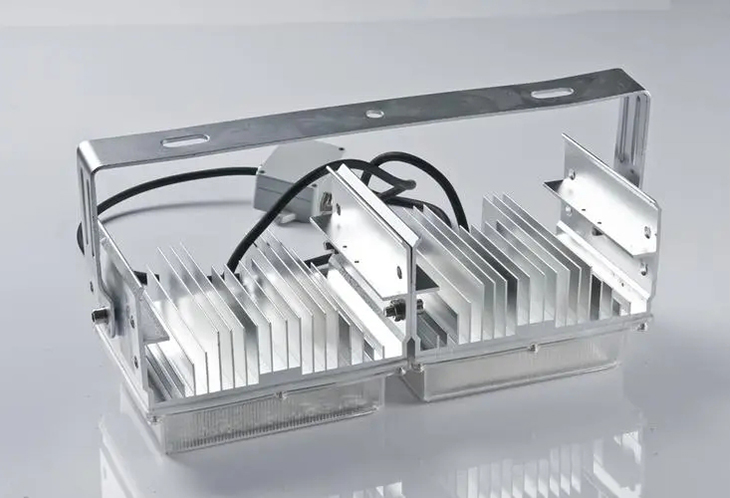

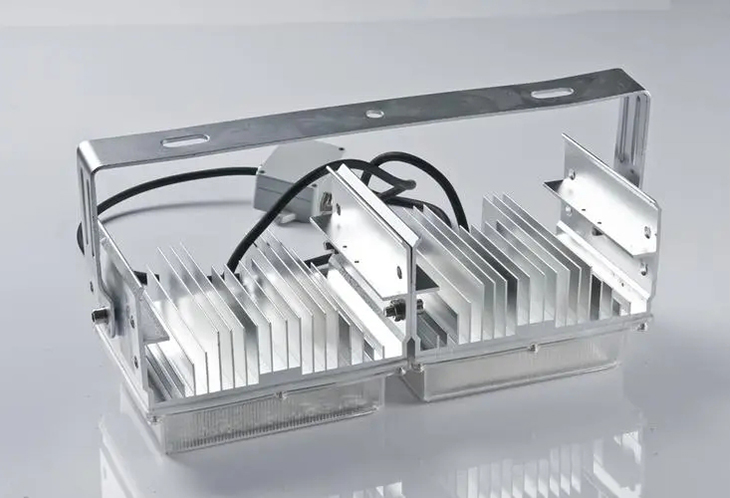

As LED technology advances, its application in lighting has become increasingly widespread. However, the heat generated by LEDs during operation, if not effectively dissipated, can impact their performance and lifespan. Therefore, addressing heat dissipation is a critical challenge in LED design. Selecting the right thermal material is crucial for enhancing the heat dissipation of LEDs. Among the various thermal materials available, thermal silicone pads have gradually become the preferred alternative to thermal grease. NFION delves into the reasons why thermal silicone pads are chosen over thermal grease in LED heat dissipation applications.

1. Thermal Performance and Stability

Thermal grease is a traditional thermal material, widely used for its excellent thermal conductivity. However, in practical applications, thermal grease has drawbacks such as high fluidity, ease of migration, and leakage, especially under high-temperature conditions. In contrast, thermal silicone pads offer high thermal conductivity while their solid-state structure ensures stability under various temperature conditions. Thermal silicone pads not only effectively fill the gaps between the LED and the heat sink, ensuring rapid heat transfer but also maintain long-term reliability, without performance degradation due to high temperatures or prolonged use.

2. Easy Installation and Maintenance

Using thermal grease requires precise application to ensure even coverage, demanding high technical skills from operators and often resulting in waste and contamination during installation. Thermal silicone pads, on the other hand, come in predetermined shapes and sizes, requiring only simple placement between the LED and the heat sink to complete the installation. This simplicity not only makes the process straightforward but also eliminates uncertainties associated with grease application. For large-scale production and assembly, thermal silicone pads significantly improve efficiency and reduce labor costs and time.

3. Environmental and Safety Concerns

Thermal grease often contains solvents and other chemicals that may impact the environment and human health over long-term use. With increasingly stringent environmental regulations, this becomes a significant drawback. Thermal silicone pads are typically made from environmentally friendly materials, free from harmful substances, and compliant with international environmental standards like RoHS and REACH. Moreover, their stable physical properties ensure they do not emit harmful gases, ensuring safety during use.

4. Long-term Reliability and Durability

Over prolonged use, thermal grease can dry out or harden, losing its thermal conductivity and thus impairing the LED's heat dissipation. Thermal silicone pads boast excellent weather resistance and durability, maintaining good thermal performance and physical properties even in harsh environments such as high temperature and high humidity. Their lifespan usually matches that of the LED, reducing maintenance frequency and replacement costs.

5. Cost-effectiveness

Although the initial cost of purchasing thermal silicone pads may be higher than thermal grease, their advantages in installation simplicity, maintenance costs, and long-term reliability make them more economically viable in the long run. Considering total cost, thermal silicone pads offer better economic value. Additionally, they reduce LED failures and replacements caused by poor heat dissipation, further lowering total ownership costs.

In summary, for LED heat dissipation applications, thermal silicone pads, with their superior thermal performance, ease of installation, environmental safety, long-term reliability, and cost-effectiveness, are gradually becoming the ideal choice over thermal grease. With ongoing technological advancements and deeper applications, thermal silicone pads will play an increasingly important role in the field of LED heat dissipation, aiding the development and popularization of LED technology.

CN >

CN >