In the assembly and maintenance of modern electronic devices, thermal grease serves as an indispensable medium for thermal conductivity, playing a vital role. Primarily used between components like CPUs and GPUs and heat sinks, it aims to fill minute gaps, enhancing heat transfer efficiency to ensure stable device operation. However, a common misconception surrounds the amount of thermal grease applied: is more necessarily better? This article delves into the consequences of excessive thermal grease application from a professional perspective, scientifically analyzing its impacts and outlining the correct application method.

The Mechanism of Thermal Grease

Firstly, understanding the fundamental function of thermal grease is essential. Composed primarily of silicone oil and fillers (such as zinc oxide or aluminum powder), it boasts excellent thermal conductivity and electrical insulation properties. When applied between a heat-generating component and a heat sink, it fills minor irregularities, establishing a continuous thermal conduction path that accelerates heat transfer from the chip to the heat sink. An ideal application is thin and even, maximizing thermal conductivity efficiency with minimal thickness.

Adverse Effects of Excessive Thermal Grease

While crucial for enhancing cooling performance, over-applying thermal grease can lead to several detrimental effects:

1. Reduced Thermal Conductivity Efficiency: Theoretically, thermal grease has a lower thermal conductivity than metal; thus, excessive amounts create a layer with higher thermal resistance between the heat source and the heat sink, hindering effective heat transfer and reducing overall cooling capability.

2. Physical Damage: Overflowing thermal grease, when heated, can seep into circuit board cracks or components, causing short circuits or corrosion, potentially damaging the board or surrounding elements severely.

3. Bubbles and Cavities: Thick applications tend to trap air bubbles during curing, which act as barriers to heat transfer, creating localized areas of increased thermal resistance and impairing cooling effectiveness.

4. Increased Maintenance Difficulty: Thermal grease requires periodic replacement to maintain optimal cooling. Over-application complicates not only the initial installation but also future cleaning and replacement processes, necessitating more time and effort.

5. Impact on Electrical Performance: Although thermal grease is inherently insulating, contact with sensitive areas on the motherboard, especially unprotected components, may still pose electrical risks.

Correct Thermal Grease Application Method

To avert these issues, proper application is imperative:

1. Preparation and Cleaning: Thoroughly clean the processor surface and heat sink base before applying thermal grease, removing old grease residue, dust, and impurities. Alcohol wipes can be gently used for this purpose.

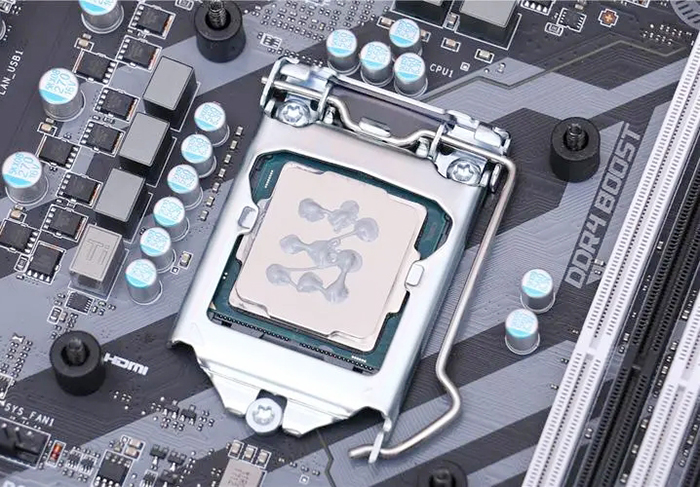

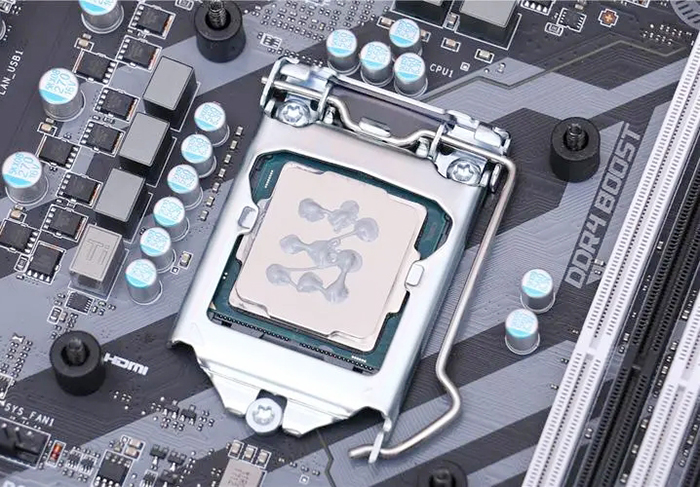

2. The Principle of Moderation: Ideally, apply thermal grease using the "rice grain" or "line" method. For most consumer-grade CPUs, a rice grain-sized amount suffices for the entire processor surface; in larger GPUs or extensive cooling interfaces, a thin line down the center, spread naturally by the pressure of the heat sink, is adequate.

3. Uniform Distribution: Gently use a hard card or a dedicated spatula to evenly spread the grease, ensuring a thin, consistent layer without lumps or voids.

4. Heat Sink Installation: After applying the grease, swiftly and smoothly install the heat sink, relying on its own pressure to evenly spread the grease. Then, follow the manufacturer's instructions to securely fasten screws.

Conclusion

Moderate application of thermal grease is pivotal to ensuring efficient cooling in electronic devices. Excess does not improve cooling but introduces a range of negative outcomes, from reduced thermal conductivity to direct physical harm to equipment. Therefore, mastering the correct application technique and meticulous attention to detail is fundamental for hardware enthusiasts and maintenance personnel alike. In the pursuit of peak performance, the seemingly insignificant yet critical step of thermal grease application must not be overlooked, ensuring every drop fulfills its intended purpose.

CN >

CN >