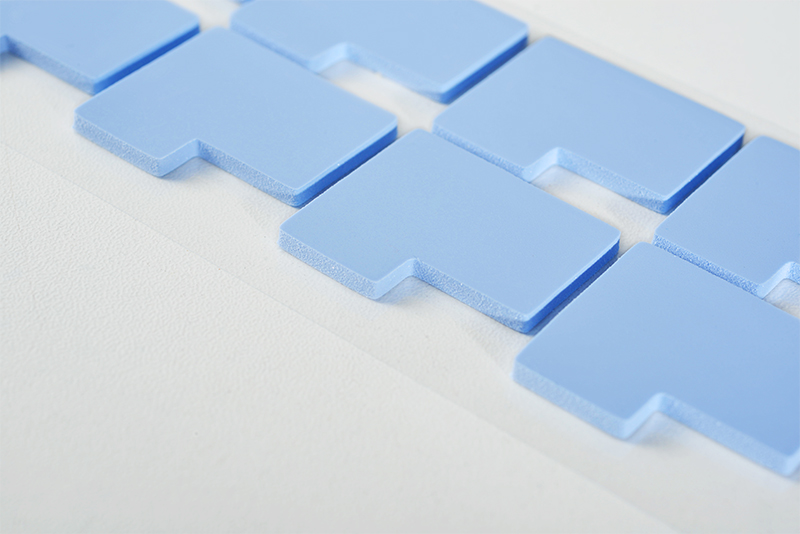

Does the Color of Silicone Thermal Pads Influence Their Performance?

Author:Nfion Thermal Pads Manufacturer

Date:2024-05-09 11:09:34

In today's era of rapidly advancing technology, thermal conductive silicone pads, as vital components in electronic device cooling solutions, have a direct impact on the stability and lifespan of these devices. When confronted with a myriad of thermal conductive silicone pad options on the market, beyond focusing on basic parameters such as thermal conductivity and temperature resistance, a seemingly trivial factor—the color of these pads—is often overlooked. Does the color of thermal conductive silicone pads actually influence their performance? This is a question worthy of thorough investigation.

Thermal conductive silicone pads are elastic materials with high thermal conductivity, proficient in heat transfer, reducing thermal resistance, and enhancing the cooling efficiency of devices. Typically, these pads come in a range of colors including white, gray, and black. Are there differences in performance and application among these differently colored pads?

From a physical properties perspective, the color of thermal conductive silicone pads is primarily determined by added pigments. These pigments themselves do not directly affect the thermal conductivity of the silicone pads. Hence, whether white, gray, or black, there is no fundamental difference in their heat transfer capabilities, as thermal performance primarily depends on the material properties and design, not the color.

However, color can influence other aspects. Firstly, it may affect visual perception and psychological interpretation of the pads. Different colors may impart different psychological cues, influencing judgments about their quality and performance. Black pads, for example, might be perceived as more professional and dependable, while white ones might seem cleaner and more hygienic.

Secondly, color may be relevant to the silicone pad's usage environment and application scenario. In contexts where neatness and aesthetics are prioritized, lighter-colored pads like white or pale shades might be more favored. Conversely, in environments with less stringent color requirements, darker pads such as black may have an advantage.

Moreover, color may be tied to the manufacturing process and cost of thermal conductive silicone pads. Pads of different colors may require distinct pigments and production methods, potentially resulting in cost variations. Pads with more unusual colors might command a higher price than those of standard hues.

For consumers, while color may not be the primary consideration, it cannot be entirely dismissed. Their focus lies more on key indicators such as thermal conductivity, reliability, and durability. Nevertheless, as an external attribute of the pads, color does play a role and can influence consumer choice in certain scenarios.

In practical applications, compatibility and coordination with other components matter. The combination of differently colored silicone pads with variously hued electronic components and heat sinks can yield different visual effects and overall aesthetic appeal. Therefore, when selecting silicone pads, considerations beyond performance and quality—such as color—should be taken into account to ensure the attractiveness and harmony of the entire system.

Additionally, we must not overlook the potential for unscrupulous vendors to exploit color to mislead consumers, claiming certain colors offer superior performance to inflate prices. Consumers must maintain rationality and vigilance, not falling prey to such marketing ploys but instead basing decisions on thorough product understanding and comparison.

From an industry development perspective, the diversification of thermal conductive silicone pad colors mirrors market demands and technological advancements. As personalization and diversity in product preferences escalate, so does the color spectrum of these pads, broadening consumer options and driving industry growth.

In summary, while the color of thermal conductive silicone pads does not directly affect their thermal performance, it can have implications in terms of visual perception, application environments, production processes, and costs. Consumers should consider all factors comprehensively, not just color. Similarly, the industry should enhance research and innovation in this area to meet the ever-increasingly diversified needs of consumers.

In future research, we can delve further into potential correlations between color and other performance aspects, exploring how optimizing color design can enhance the performance and application effectiveness of thermal conductive silicone pads. Additionally, studying the performance of differently colored pads in various environments and applications can provide a more scientific basis for practical use.

As technology progresses and our understanding of thermal conductive silicone pads deepens, we anticipate more comprehensive and profound research and comprehension of color-related issues. We look forward to a future market abound with high-performance, color-diverse silicone pads, offering more reliable and efficient support for various electronic devices and thermal management systems.

In conclusion, while the color of thermal conductive silicone pads is not the determining factor of performance, it indeed holds some influence in certain respects. By approaching this issue with a scientific mindset, recognizing the role and significance of color, while avoiding being misled by it, we can make better choices and utilize thermal conductive silicone pads more effectively, thus enhancing convenience and efficiency in our daily lives and work.

CN >

CN >