What Are the Key Uses of Silicone Thermal Grease?

Author:NFION

Date:2024-06-15 13:56:20

Silicone thermal grease, also known as thermal paste or thermal compound, plays a critical role in the realm of electronics and computing. It is a specialized material designed to enhance thermal conductivity between components, ensuring efficient heat dissipation and optimal performance.

Understanding Silicone Thermal Grease

Silicone thermal grease is composed of silicone oil combined with thermally conductive fillers such as metal oxides. This unique formulation provides a balance between thermal conductivity and electrical insulation. The primary purpose of this compound is to fill microscopic air gaps and irregularities between surfaces, thereby facilitating superior heat transfer.

Key Applications of Silicone Thermal Grease

1. Computing and Electronics

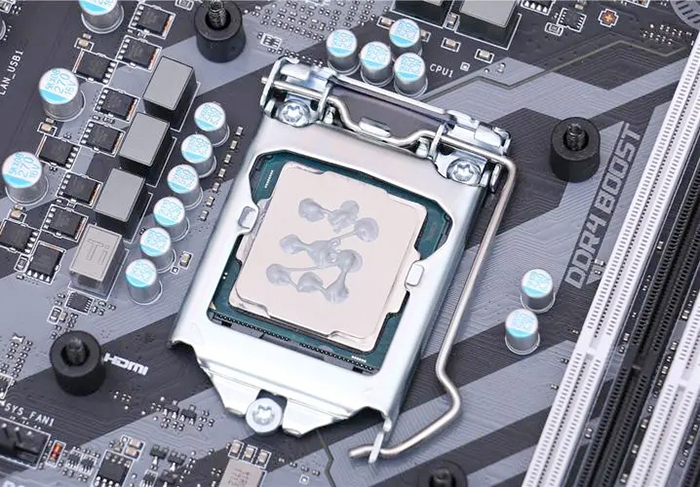

One of the most prominent applications of silicone thermal grease is in the computing industry. CPUs and GPUs generate substantial heat during operation. To maintain performance and prevent overheating, efficient heat dissipation is crucial. Silicone thermal grease is applied between the processor and the heat sink to ensure maximum thermal conductivity. This prevents thermal throttling, maintains system stability, and prolongs the lifespan of the components.

2. Power Electronics

In power electronics, devices such as transistors, diodes, and power modules also produce significant heat. Effective thermal management is essential to avoid thermal runaway and potential damage. Silicone thermal grease is used to enhance the thermal interface between power semiconductors and their heat sinks, ensuring efficient heat dissipation and reliable operation.

3. LED Lighting

LED lighting systems, known for their energy efficiency and long lifespan, can suffer from heat accumulation, which affects performance and longevity. Silicone thermal grease is utilized to improve thermal management in LED modules, helping to maintain optimal operating temperatures and extending the lifespan of the LEDs.

4. Automotive Electronics

Modern vehicles are equipped with numerous electronic systems, including engine control units (ECUs), infotainment systems, and advanced driver-assistance systems (ADAS). These components generate heat that must be managed effectively. Silicone thermal grease is applied to ensure efficient heat dissipation, thereby enhancing the reliability and durability of automotive electronics.

5. Telecommunications

Telecommunications equipment, such as base stations and network servers, operate continuously and generate substantial heat. Silicone thermal grease is used to maintain effective thermal management, ensuring uninterrupted operation and minimizing the risk of overheating-related failures.

Benefits of Silicone Thermal Grease

The widespread use of silicone thermal grease can be attributed to several key benefits:

1. Enhanced Thermal Conductivity

Silicone thermal grease significantly improves thermal conductivity between surfaces, reducing the thermal resistance and ensuring efficient heat transfer. This is essential for maintaining the performance and reliability of electronic components.

2. Electrical Insulation

While providing excellent thermal conductivity, silicone thermal grease also acts as an electrical insulator. This property is crucial for preventing electrical short circuits and ensuring the safe operation of electronic devices.

3. Easy Application

Silicone thermal grease is typically easy to apply and can be spread uniformly over surfaces. This ensures consistent thermal performance and reduces the risk of overheating due to improper application.

4. Durability and Stability

High-quality silicone thermal grease is designed to withstand various environmental conditions, including high temperatures and humidity. This durability ensures long-term performance and reliability in diverse applications.

Conclusion

Silicone thermal grease is an indispensable material in the field of electronics and computing, offering a critical solution for thermal management. Its applications span a wide range of industries, from computing and power electronics to automotive and telecommunications. By enhancing thermal conductivity and providing electrical insulation, silicone thermal grease ensures the optimal performance, reliability, and longevity of electronic components. Understanding its importance and proper application is essential for anyone involved in the design, manufacturing, and maintenance of electronic systems.

CN >

CN >