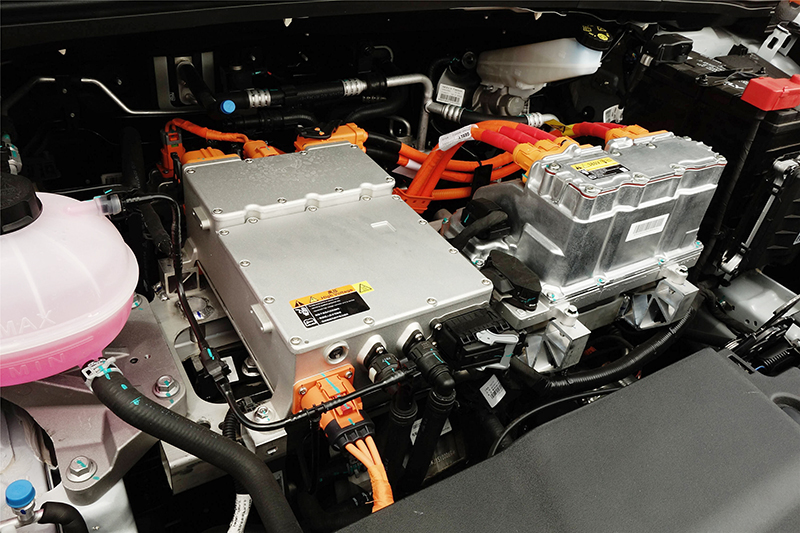

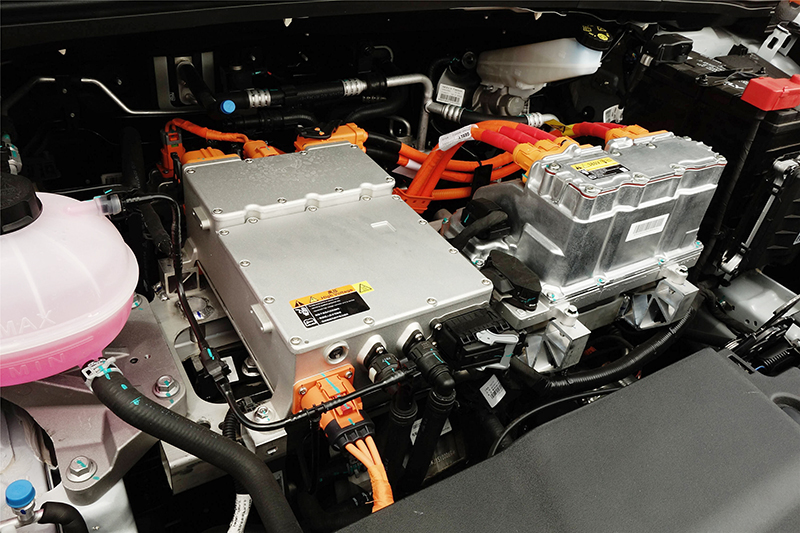

The application of thermal conductive silicone pads in On-Board Charger (OBC) for electric vehicles is primarily reflected in heat dissipation management and electrical insulation, ensuring the high efficiency, stability, and safety of the charger's operation.

As a critical component of an electric vehicle's energy replenishment system, the OBC converts external alternating current into direct current to charge the vehicle's battery. This process generates substantial heat, particularly within power semiconductor modules and other high-temperature electronic components. If this heat is not effectively dissipated, it can lead to overheating, affecting performance and lifespan or even posing potential safety hazards.

The application of thermal conductive silicone pads in OBC mainly involves:

1. Heat Dissipation Management:

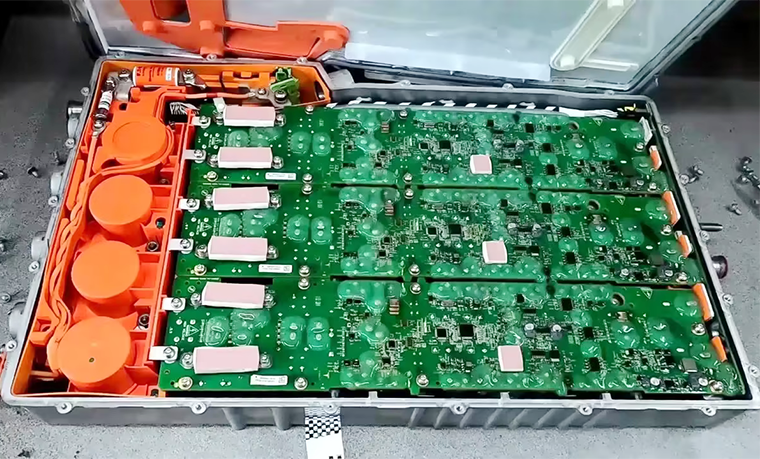

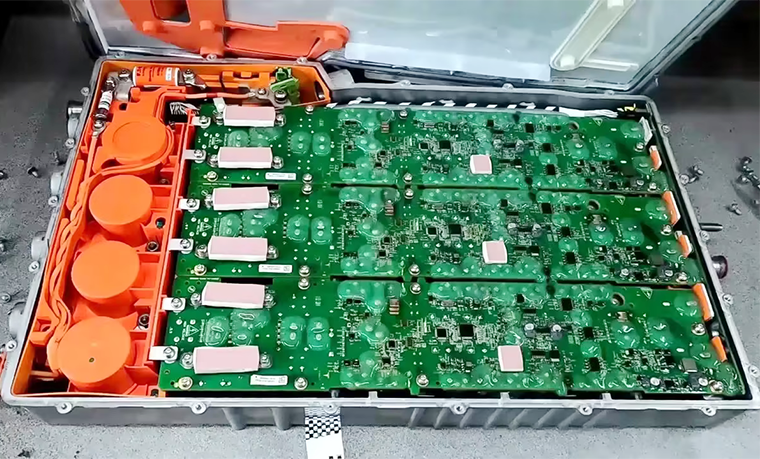

During operation, OBC generate considerable heat, especially from power electronic components like power semiconductor devices (such as IGBT and MOSFET), control chips, etc., which rapidly heat up due to high-power conversion. The thermal conductive silicone pad, with its excellent heat transfer properties, fills the gaps between these heat-generating elements and heat sinks or casings, creating an efficient thermal pathway to quickly dissipate the generated heat. This prevents overheating that could cause performance degradation or damage to the components.

2. Electrical Insulation:

Thermal conductive silicone pads not only offer high thermal conductivity but also provide good electrical insulation. In the complex electrical environment inside the OBC, they ensure effective electrical isolation between different PCB assemblies while facilitating efficient cooling, thus avoiding short-circuit risks.

3. Mechanical Buffering and Shock Absorption:

During vehicle operation, uneven road surfaces and bumps can cause vibrations and impacts on the OBC. The elastic nature of the thermal conductive silicone pads allows them to absorb and distribute these stresses to some extent, thereby protecting delicate internal components from damage.

4. Adaptability to Complex Environments:

OBC must operate reliably under various harsh conditions, including temperature fluctuations and humidity changes. High-quality thermal conductive silicone pads maintain stable performance over a wide temperature range and possess excellent weather resistance and chemical stability, meeting the demands of automotive applications.

Moreover, the thickness of thermal conductive silicone pads is adjustable, allowing for customization according to the actual distance between heat-generating elements and cooling devices, ensuring optimal contact area and pressure, thereby further enhancing cooling efficiency. Its ease of installation and handling also simplifies the production assembly process, reducing both production and maintenance costs.

In the context of the miniaturization and lightweight trend of OBC, thermal conductive silicone pads, being thin, flexible, and high-performance heat management solutions, better meet the requirements for compact layouts and contribute to more efficient space utilization and system integration.

Additionally, some thermal conductive silicone pads have strong self-adhesive properties, adhering firmly to the surface of heat-generating components without the need for additional fixing devices, enhancing product integrity and sealing, which helps prevent dust and moisture ingress, thus improving the working environment quality of the OBC.

In summary, thermal conductive silicone pads are a vital part of the thermal management solution for OBC, playing an indispensable role in extending the charger's service life and maintaining stable charging performance. Their application in OBC contributes to enhancing overall system thermal stability, extending operational life, ensuring safe operation, and optimizing the charger's overall design and efficiency.

Thus, selecting the appropriate thermal conductive silicone pad as a heat management material during the design and manufacture of OBC is crucial for ensuring the reliability and longevity of the charger's operation.

CN >

CN >