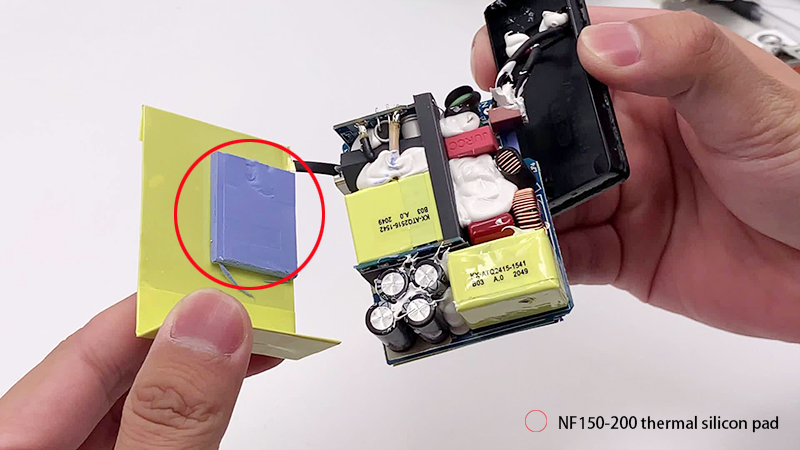

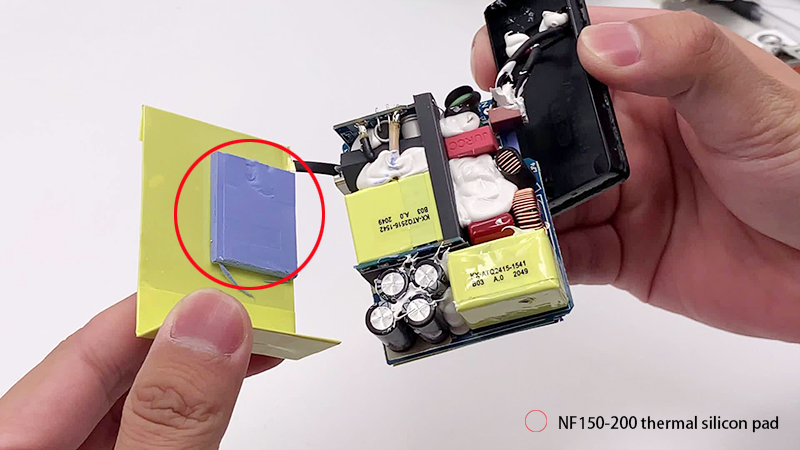

With the continuous progress of technology, high-power charging heads have become a must-have tool for charging modern electronic equipment. During the manufacturing process of high-power charging heads, thermal silicon pad plays a vital role. It not only improves charging efficiency, but also ensures the safety and stability of the charging process.

In high-power charging heads, heat-conducting silicon pads are mainly used for assisting heat dissipation. Because the high-power charging head will generate a lot of heat during the work process, if it cannot be dispersed in time, it will not only affect the charging efficiency, but also cause device damage or even fire. Therefore, the application of thermal silicon pad is particularly important.

Thermal conductive silicon pad plays a key heat dissipation effect in the application of high-power charging heads to ensure that charging equipment maintains safe, stable and longevity while maintaining efficient work. So what are the characteristics and advantages of thermal silicon pad in the application of high-power charging heads?

1. Thermal management function:

High-efficiency thermal conductivity: Thermal conductivity has a high thermal conductivity (such as 1.0W/m.K to 12.0W/m.k, or even higher), which can effectively put the internal components of the charging head (such as power management chips, transformers, rectifiers, etc. ) The generated heat is quickly passed to the heat dissipation structure (such as metal shell, heat sink, etc.). This helps reduce the temperature of the heat source and prevent hidden dangers from decreased performance due to overheating.

2. Gap filling:

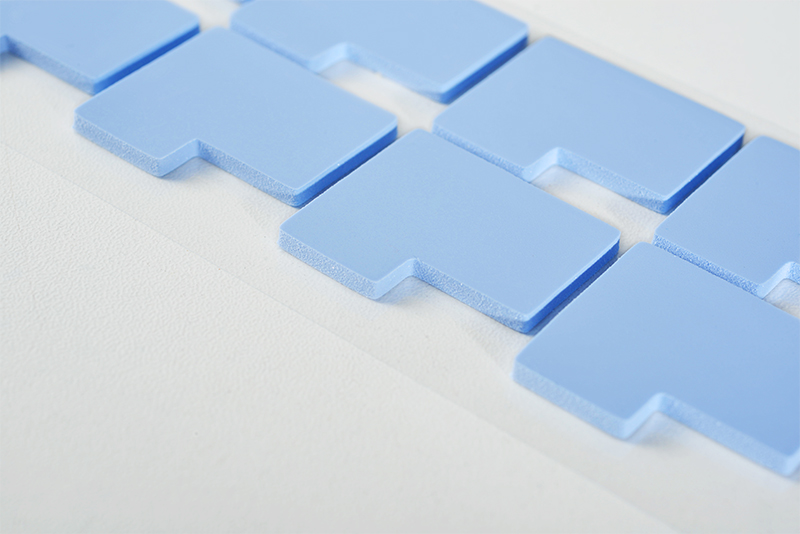

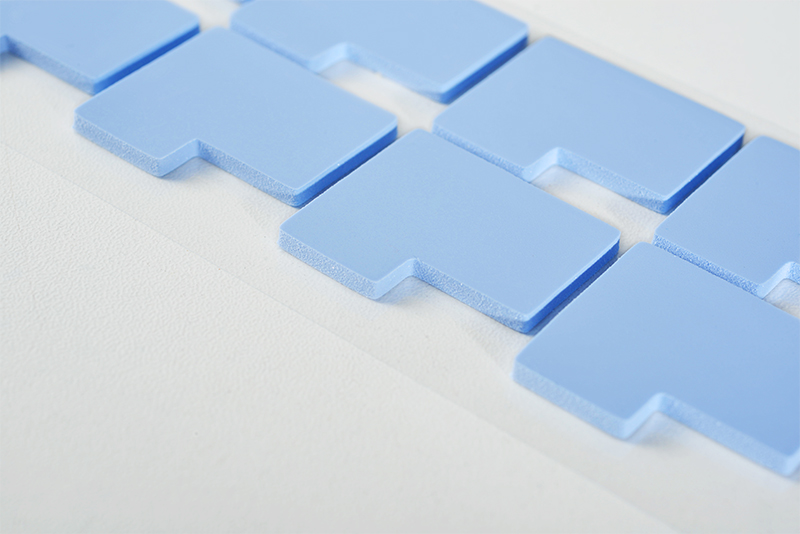

The space inside the high-power charging head is compact, and there may be a small air gap between components. Due to its soft and compressed characteristics, heat-conducting silicon sheets can closely fit between the thermal components and the heat sink, fill these irregular or tiny gaps, forming an effective thermal conductivity, reducing thermal resistance and improving the overall heat dissipation efficiency.

3. Insulation protection:

Thermal conductivity silicon pad has good electrical insulation performance. While ensuring efficient heat dissipation, it isolate components of different voltage levels, prevent the risk of short circuit or arc discharge, and ensure the electrical safety of the charging head.

4. Mechanical buffer and shock absorption:

The elastic heat-conducting silicon pad can absorb and alleviate the vibration and stress produced during the operation of the internal component, protect the physical impact of sensitive electronic components, and enhance the overall structure stability of the charging head.

5. Adaptability and craftsmanship:

Thermal conductive silicon pad can be cut into various shapes and sizes as needed to adapt to the complex structural layout in the high-power charging head. Its self-adhesion or the use of auxiliary adhesives can be easily installed and fixed without complex processes, which is conducive to assembly and maintenance in large -scale production.

6. Environmental tolerance:

High-quality heat-conducting silicon pad usually has a wide working temperature range (such as -40-200℃), which can withstand the temperature changes of the charging head under various environmental conditions (such as cold start, high temperature operation, fast charging and discharge, etc.). , Maintain stable thermal conductivity and physical form.

7. Compliance and certification:

For specific application scenarios such as vehicle chargers, thermal silicon pad may also need to meet specific flame retardant standards (such as UL 94 V-0) to ensure that when abnormal conditions occur, the flame spread can be effectively suppressed, which meets the safety requirements of automotive electronic equipment. Essence

In summary, with its excellent thermal conductivity, good insulation, highly adaptable flexibility, and easy processing, with its excellent thermal conductivity, good thermal conductivity, good insulation, adaptability, and easy processing The cooling challenge brought by high-power charging provides a reliable, economical and easy to implement solution. With the advancement of technological, the performance of thermal silicon pad has been continuously optimized, such as improving thermal conductivity, enhancing flame retardant, and developing low volatile environmental protection formulas to adapt to the charging equipment to higher power density, smaller volume, and rigorous environmental conditions development trend.

CN >

CN >