How much do you know about the application of thermal silicon pad in the router?

With the continuous development of science and technology, routers, as an important hub for family and corporate networks, their performance and stability are increasingly attracting people. In this process, the problem of heat dissipation has become one of the key factors to restrict the improvement of router. To solve this problem, thermal silicon pad is widely used in the heat dissipation system of the router, providing a strong guarantee for the stable operation of the router.

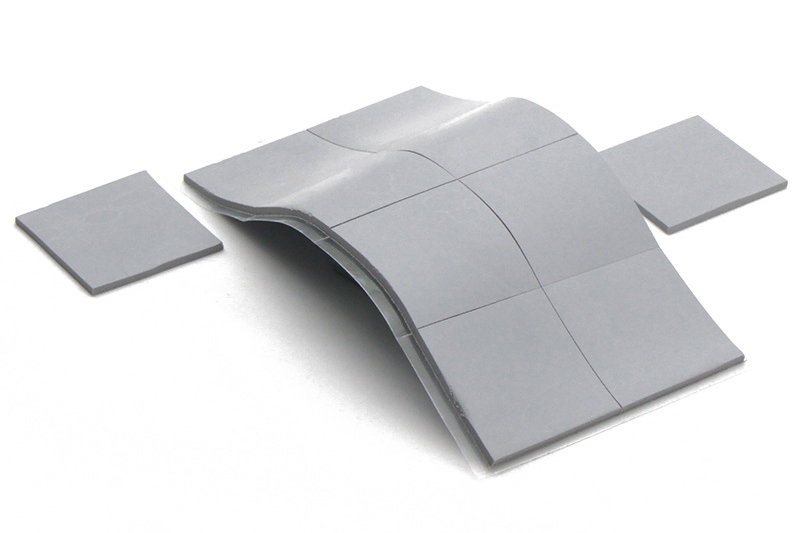

Thermal conductivity silicon pad is a high-performance thermal conductive material. It has good thermal conductivity and insulation performance. It can effectively pass the heat generated by the router to prevent heat from accumulating inside the router, thereby ensuring the normal operation of the router. At the same time, heat-conducting silicon pad also has certain elasticity and softness, which can well adapt to the complex structure inside the router and ensure the maximum heat dissipation effect.

The application of thermal silicon pad in the router mainly revolves around a large amount of heat generated inside the device to ensure that the router maintains stable temperature and good working performance during the continuous operation. The following are the specific aspects and application details of thermal silicon pad in the router:

1. Heating medium:

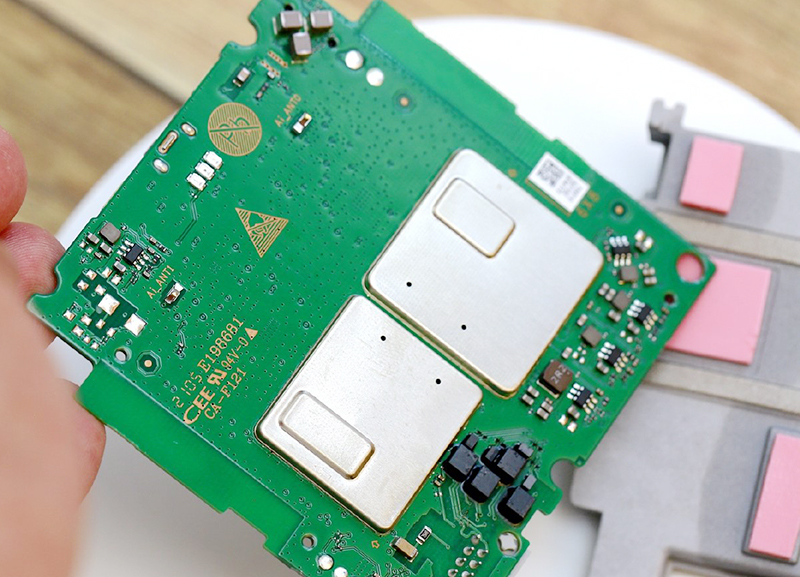

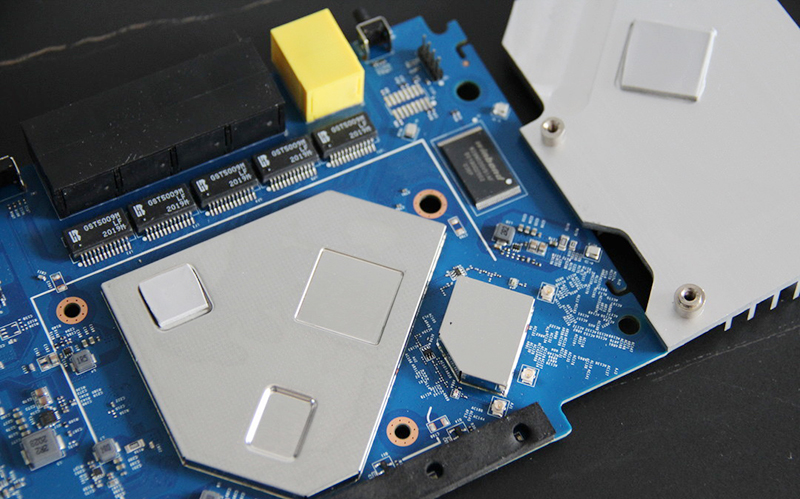

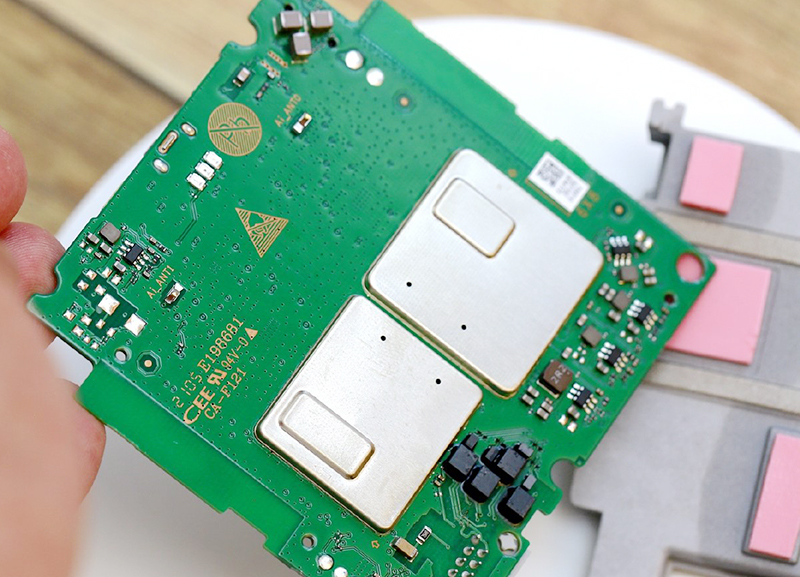

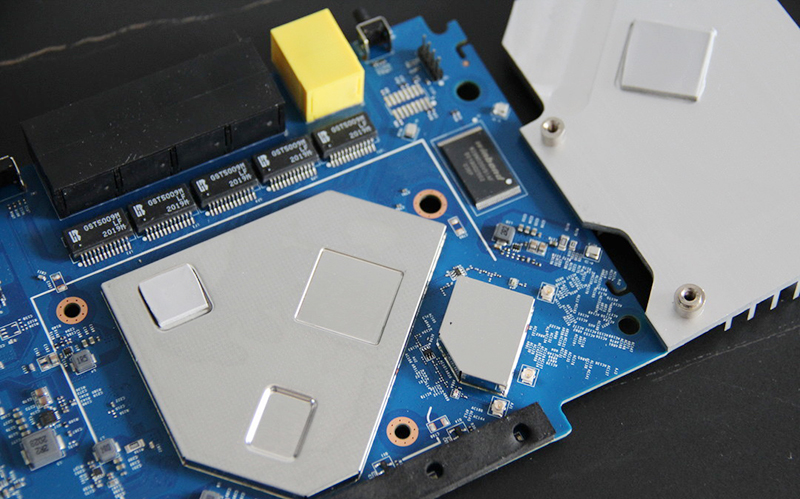

Heat transfer between thermal source and radiator: CPU, Wi-Fi chip, SOC, DDR memory, and switching chips such as CPUs, Wi-Fi chips, SOC, DDR memory, and switching chips will generate a lot of heat. Thermal conductivity silicon pad is placed between these thermal components and the heat sink or shell to act as a high-efficiency thermal conductivity. Its soft characteristics allow it to closely fit the heat of the heat hair and heat dissipation surfaces, reduce the air gap, reduce the thermal resistance, and make the heat quickly transmitted from the heating source to the heat dissipation system.

2. Fill the gap and surface adaptation:

Copy uneven surface: Because circuit board components, heat sinks, or shells may have tiny manufacturing or unevenness, thermal silicon pad has good flexibility and compression, can fill these gaps well, ensure the maximum heat contact area, Improve heat dissipation efficiency.

Seismic buffer: In addition to thermal conductivity, the silicon pad also provides a certain amount of shock absorption effect, protecting sensitive electronic components from damage caused by vibration or impact.

3. Flexibility of thermal management design:

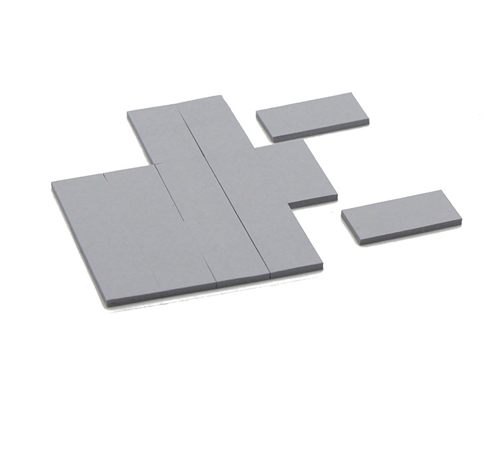

Adapt to compact space: As the volume of the router tends to miniaturize, the internal space layout is more compact. Due to the adjustment of the thickness and cutting of the thermal silicon pad, it can adapt to various complex space restrictions and facilitate engineers to carry out flexible thermal design.

4. Insulation and protection:

Electrical isolation: Thermal silicon pad has excellent insulation performance, which can prevent short circuits between components of different voltage levels and ensure the safe operation of equipment.

Anti-interference: In certain applications, thermal silicon pad may be used with metal shielding cover, which can not only help heat dissipation, but also play an electromagnetic shielding effect, reduce the electromagnetic interference of the internal component to the external environment or the sensitivity of external electromagnetic interference.

5. Specific application scenarios:

5G router antenna module heat dissipation: For the high power requirements of 5G communication routers and higher heat dissipation challenges, dedicated high-heat coefficient silicon pad (such as NF150-600,6.0W/m.K) is used for heat dissipation management of antenna module, and effectively concentrates. The heat generated quickly dispersed into the heat dissipation system.

6. System-level heat dissipation strategy:

Multi-point heat dissipation: The router may use the PCB board to heat the heat dissipation. The shield on the front chip is connected to the heat sink through the thermal conductive gel, and the back is attached to the heat-conducting silicon pad to achieve a comprehensive and multi-channel heat tutoring.

In summary, the application of thermal silicon pad in the router is not limited to simple thermal conductivity, but also involves space optimization, seismic protection, electrical isolation, and cooling demand for the development of specific technologies (such as 5G). Its multi-functional characteristics and flexibility in thermal design make it a key component in modern router cooling solutions.

CN >

CN >