In the application of power batteries, thermal silicon pad plays a vital role. With the rapid growth of the electric vehicle market, the performance requirements of power batteries are becoming stricter. As an efficient thermal management material, thermal conductivity silicon pad, its excellent thermal conductivity and stable chemical properties, make it play an irreplaceable role in thermal management of power batteries.

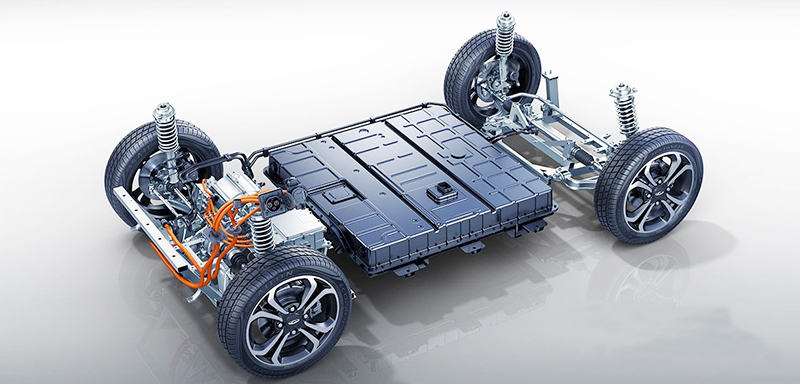

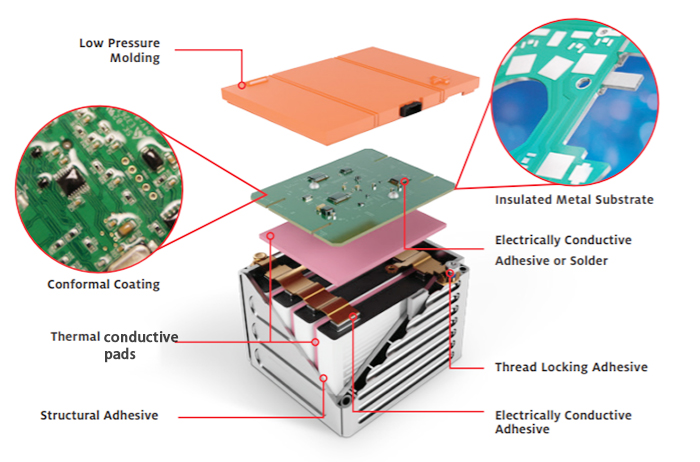

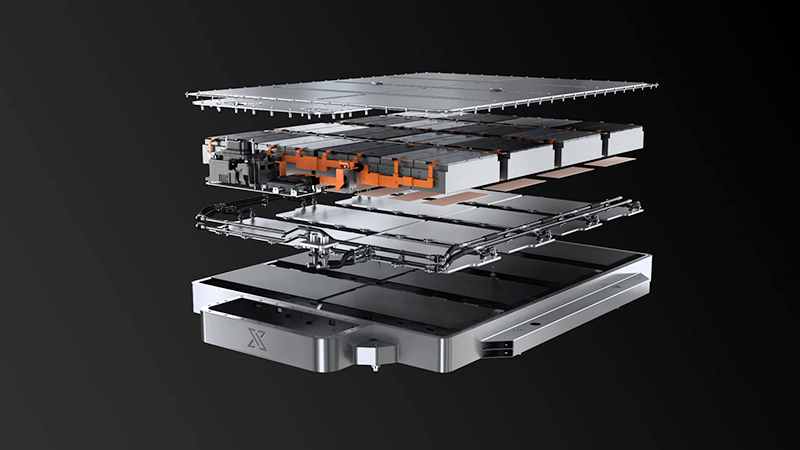

Temperature balance: Power batteries will generate a lot of heat during the working process, especially when fast charging or high power runtime. If these heat is not dispersed in time and effectively, the internal temperature of the battery may cause uneven temperature and local heat, which will affect the performance, safety and service life of the battery. Because of its good thermal conductivity, heating silicon pad is used inside the battery pack. It is attached between the battery monomer or between the battery module and the shell. (Such as aluminum shells or liquid cold plates, etc.), thereby helping maintain the temperature difference between the temperature between the parts of the battery pack to control the safe range, and it is usually required to not exceed 5℃.

Electrical safety: The thermal silicon pad is used as an insulation material and has good electrical insulation performance. It can prevent short circuits between different components inside the battery and ensure the electrical safety of the battery system. In addition, its chemical properties are stable, high-temperature and anti -aging, can resist chemical erosion in the battery working environment and provide additional protective layers.

Flexible design: For the power batteries of different models and structures, thermal silicon pad can be customized according to actual needs to customize the thickness, hardness, thermal conductivity coefficient to meet different heat dissipation requirements and space restrictions. In addition, some thermal silicon pads may also add special additives to enhance specific performance, such as improving refractory levels and improving compression -based transformation, etc., to meet the specific needs of power batteries in different application scenarios.

CN >

CN >