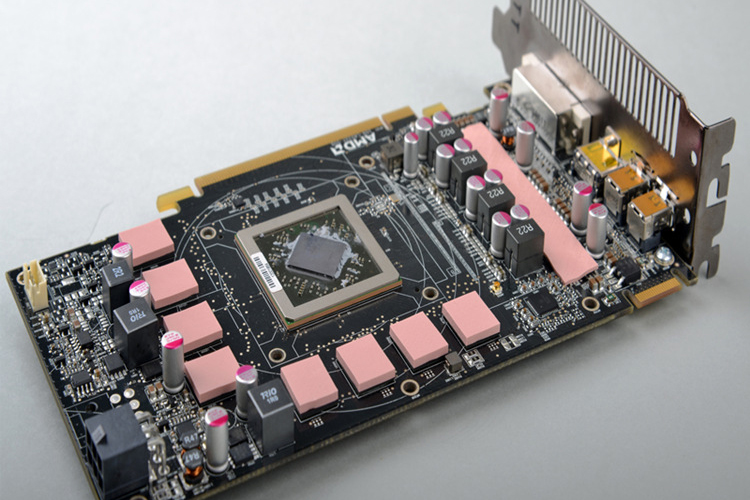

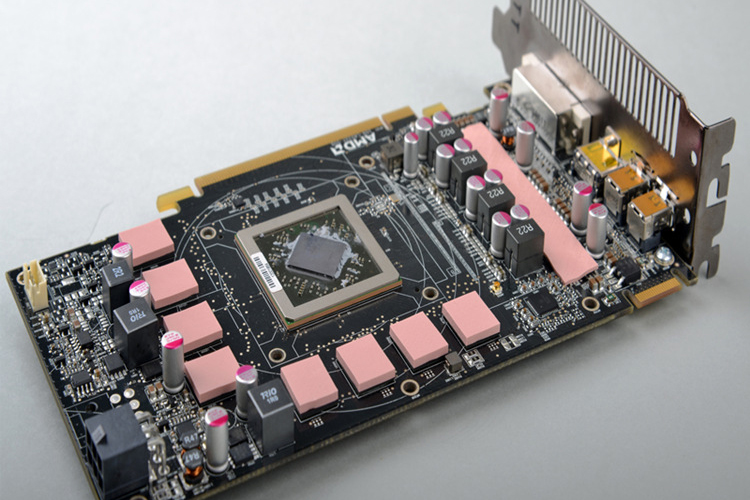

Thermal conductivity silicon pad is a high performance thermal material widely used in the field of electronic equipment heat dissipation. Due to its excellent thermal conductivity and good electrical insulation performance, thermal silicon pad is widely used in the connection between CPUs,GPUs,power and other heat sources to improve heat dissipation efficiency and ensure the stable operation of the equipment. This article will introduce the production process of thermal silicon pad in detail, including the steps of raw material preparation, mixing, molding, vulcanization, cutting and inspection and other steps.

1. Raw material preparation

The main raw materials of thermal silicon pad include silicone, heat -conducting gap fillers and additives. Among them, silicone is a matrix material, which is responsible for providing the elasticity and temperature resistance of silicon pad; thermal filler is responsible for improving the thermal conductivity of the silicon pad. Common thermal conductive fillers include metal oxides, graphite, carbon nanotubes, etc. The performance of silicon pads, such as plasticizers, sulfurizers, anti-aging agents,etc.

Before production, the raw materials need to be strictly inspected to ensure that its quality meets production requirements. At the same time, according to the production process and product performance requirements, the proportion of raw materials reasonably is to achieve the best product performance.

2.Mixture

Mixing silicone, heat conduction fillers, and additives is evenly mixed according to a certain proportion, which is a key step in the production of thermal silicon pad. During the mix, you need to choose the appropriate mud device, such as planetary mixer, vacuum mixer, etc. to ensure that the raw materials are fully mixed and uniform. At the same time, temperature and time need to be controlled during the mix to avoid heat degradation or oxidation of raw materials.

3. Molding

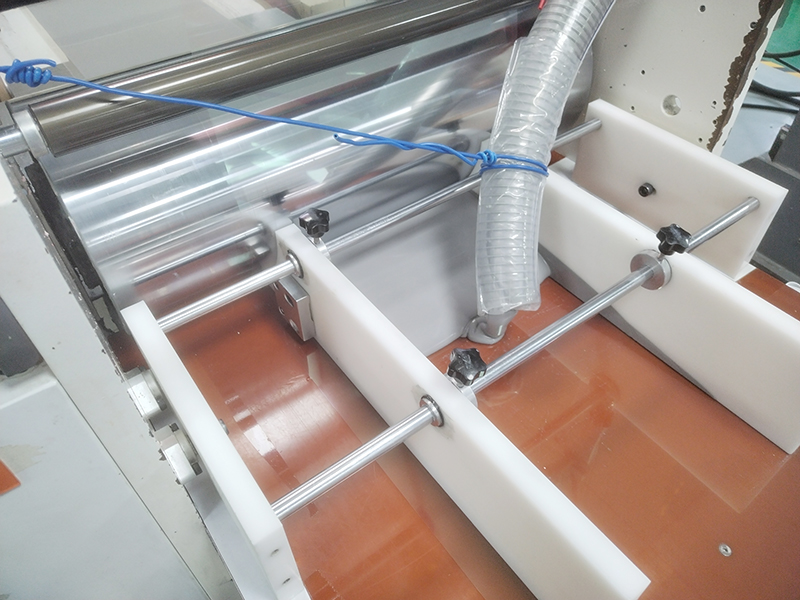

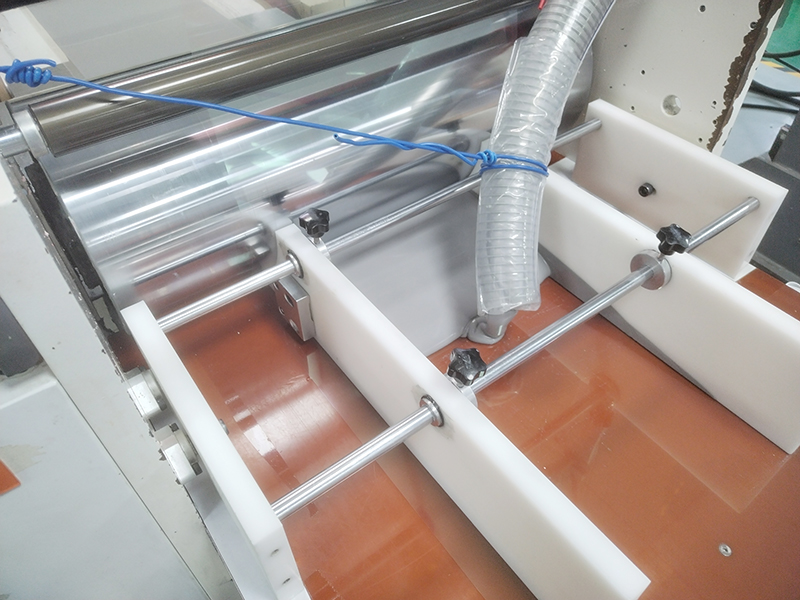

After the mix is completed, put the mixed materials into the molding equipment for molding operations. Common molding equipment include flat sulfur, injection molding machine, etc. During the molding process, the molding pressure, temperature and time need to be controlled to ensure the size and accuracy of the finished product and the uniformity of the internal structure.

4. Vulcanization

The formation of thermal conduction silicon pad needs to be sulfid to improve its mechanical properties and stability. During the process of vulcanization, the appropriate sulfur and sulfide are needed, such as vulcanization temperature, time, and pressure. After the vulcanization is completed, sufficient cooling is needed to avoid deformation or cracking of the product.

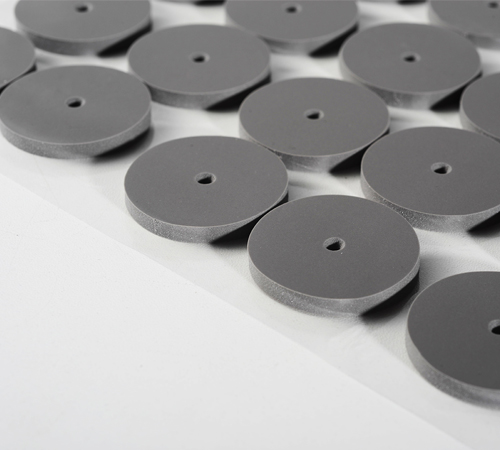

5. Cutting and testing

After the completion of vulcanization, thermal conductivity silicon pad needs to be cut to meet the needs of different customers. During the cutting process, you need to choose the appropriate cutting equipment and cutting process to ensure the size accuracy and appearance quality of the product. At the same time, it is necessary to pay attention to prevent defects such as burrs or cracks during cutting.

After the cutting is completed, it is necessary to strictly inspect the thermal silicon pad, including appearance inspection, size measurement, thermal conductivity testing, etc. Only the inspection products can be identified as a qualified product, enter the next process or sell them to customers.

6. Packaging and storage

Qualified thermal conduction silicon pad needs to be packed to protect the product from being damaged during transportation and storage. Common packaging methods include vacuum packaging, plastic bag packaging, etc. During the packaging process, you need to pay attention to avoid stress or friction of the product, so as not to cause damage or deformation.

After the packaging is completed, the heat -conducting silicon pad needs to be stored in a dry, cool, and ventilated place to avoid direct sunlight or high temperature environment. At the same time, it is necessary to regularly flip and check to ensure the quality and performance of the product.

In summary, the production process of thermal silicon pad includes steps such as raw material preparation, mixing, molding, vulcanization, cutting and inspection, and packaging and storage. During the production process, the parameters and quality requirements of each process need to be strictly controlled to ensure the performance and stability of the product to reach the best state. At the same time, it is necessary to continuously improve the production process and equipment, improve production efficiency and product quality, to meet the needs of customers and the development of the market.

CN >

CN >